Forward-reverse-forward three-stage drilling mechanical rock breaking and shaft sinking method

A raise well drilling rig and forward technology, which is applied in the direction of reverse well sinking, well sinking, shaft equipment, etc., can solve problems such as construction of large-diameter shaft shafts, and achieve the effect of high degree of mechanization and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

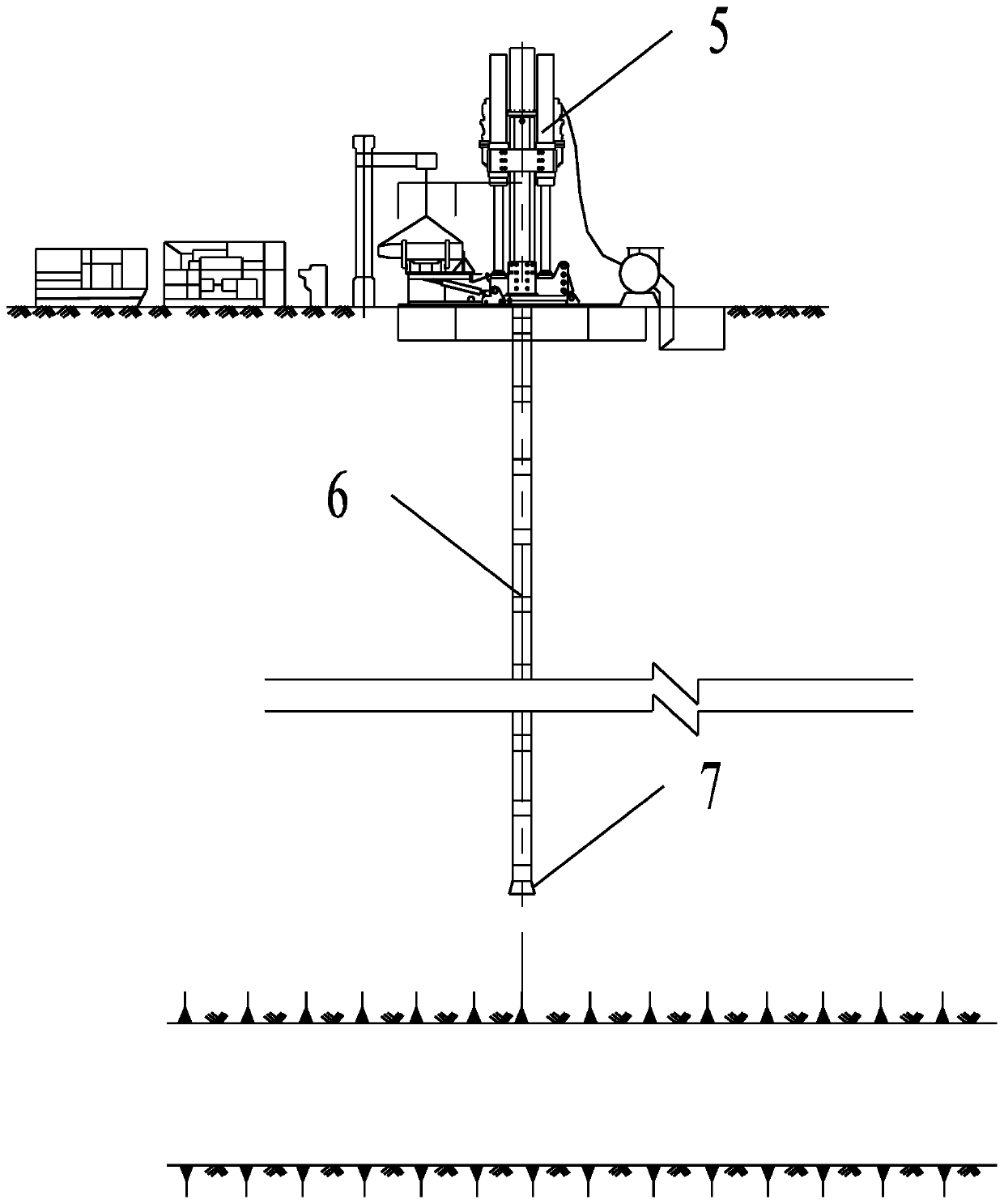

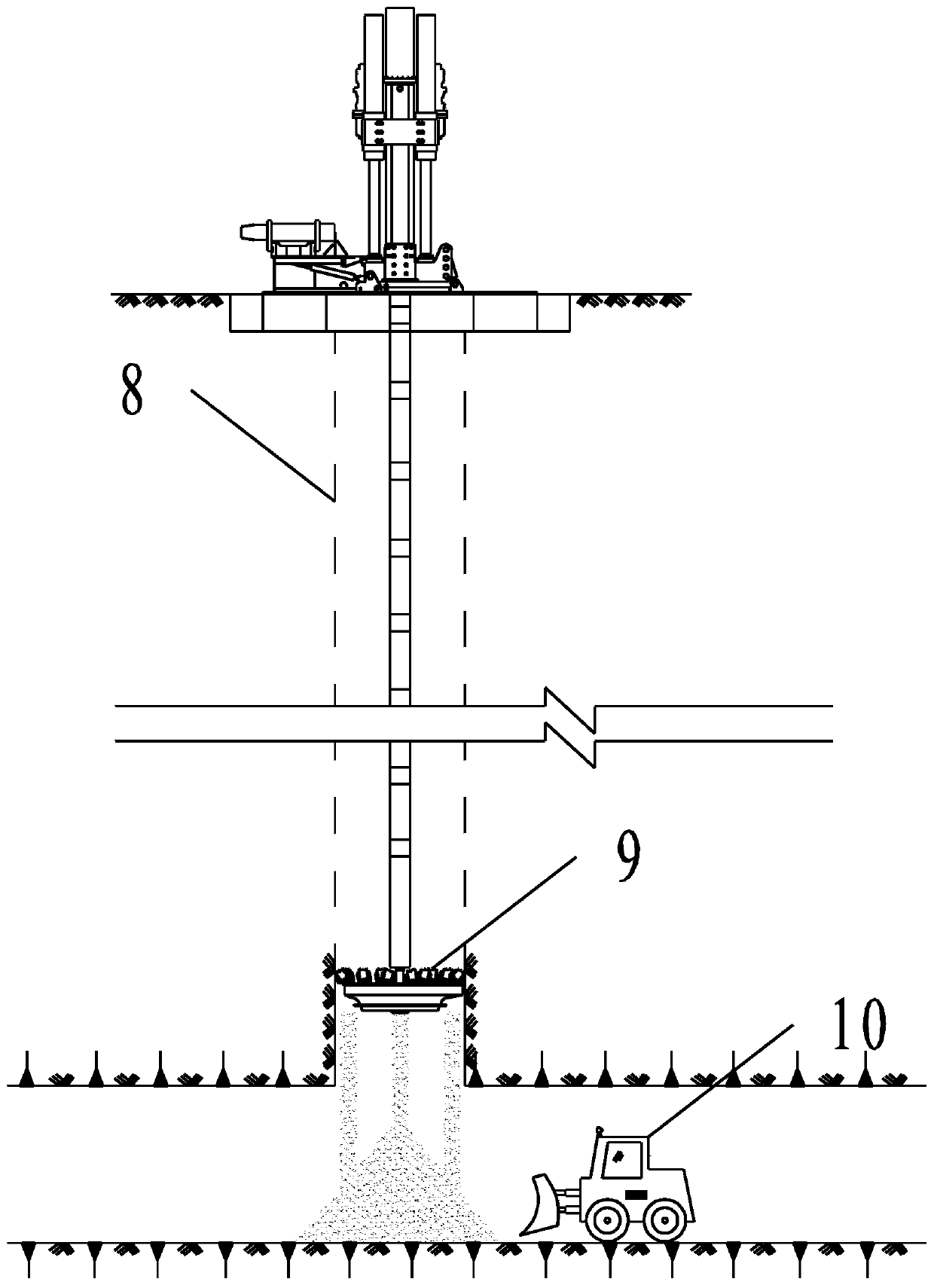

[0031] Forward-reverse-forward three-stage drilling mechanical rock-breaking drilling method:

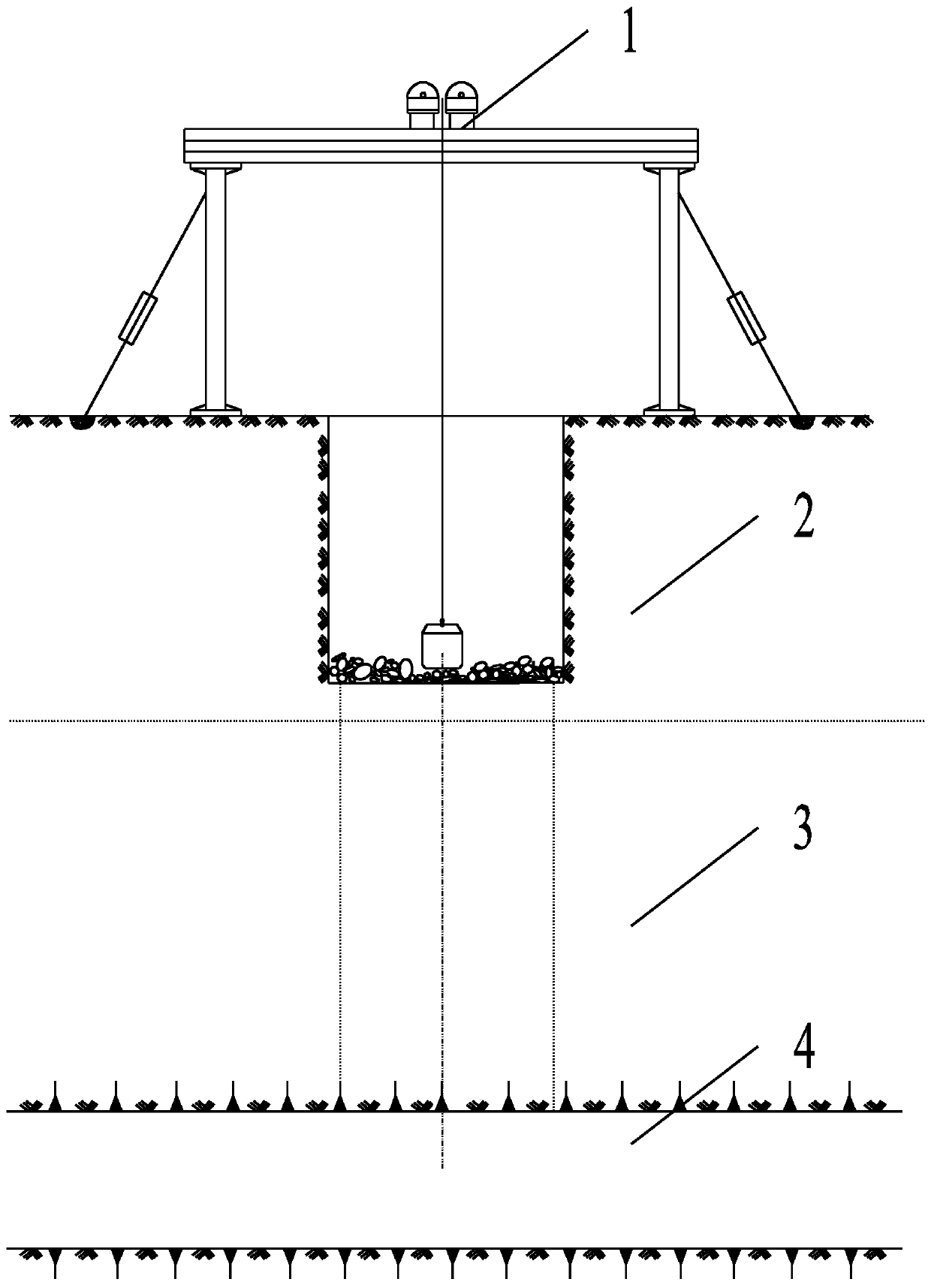

[0032] (A) Wellbore excavation preparations, such as figure 1 shown.

[0033] (A-1) Using the roadway or tunnel that has been formed by the shaft, in the upper horizontal roadway or tunnel, based on the intersection of the axis of the shaft and the axis of the upper horizontal roadway or tunnel, and according to the maximum weight and volume of a single piece of equipment used, design Auxiliary tunnel to reach the required section;

[0034] (A-2) According to the weight and volume of the tunneling equipment, install the lifting equipment steel structure 1;

[0035] (A-3) Carry out lock opening excavation and support, and construct a concrete foundation that meets the requirements of the raising drilling rig equipment; the lock opening is excavated from the unstable topsoil layer 2 to the stable rock 3, pouring well wall concrete, constructing the drilling rig foundation, and pre- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com