Pressure reducing valve with pressure chamber

A pressure chamber and pressure reducing valve technology, applied in the field of pressure reducing valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

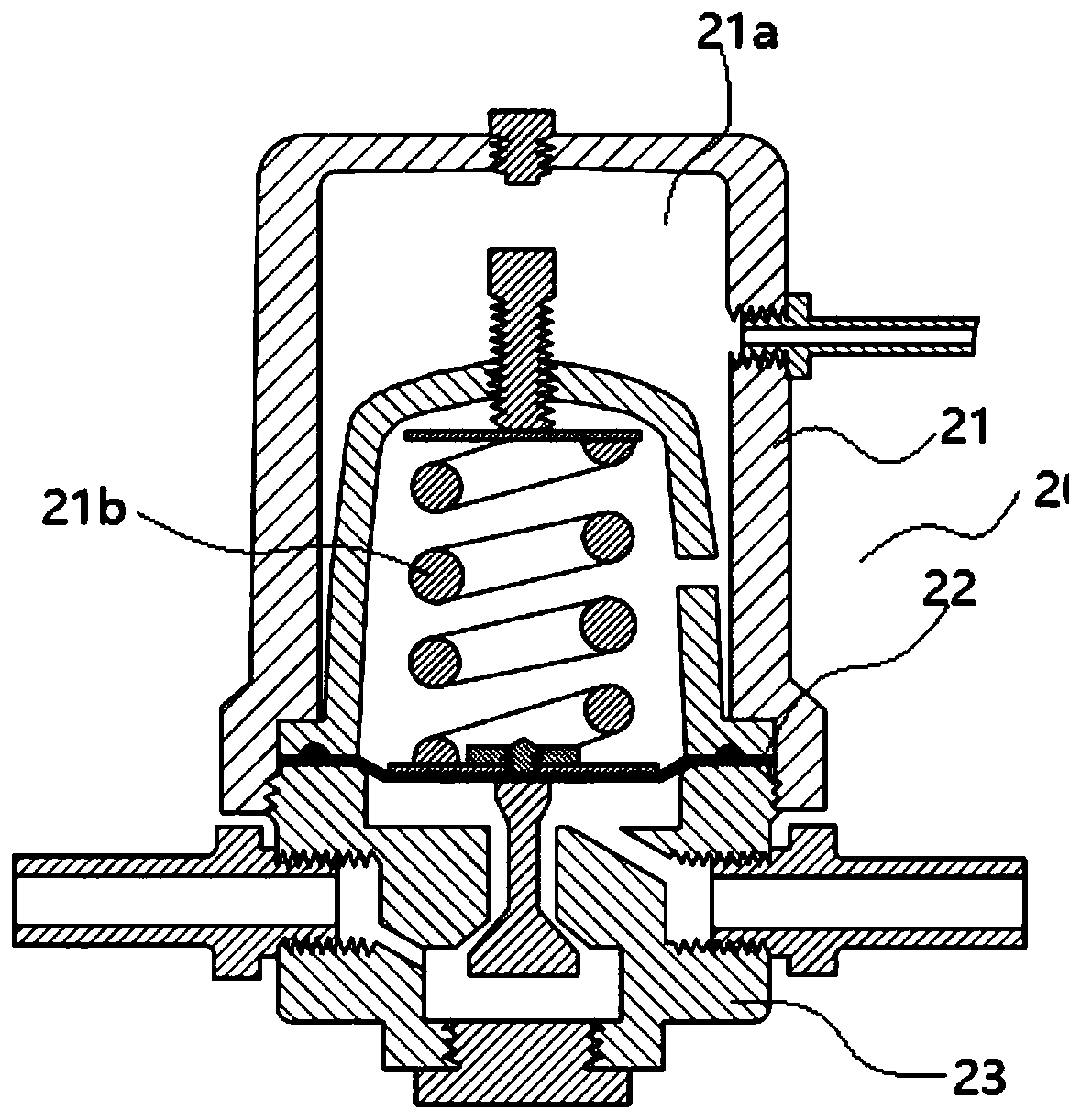

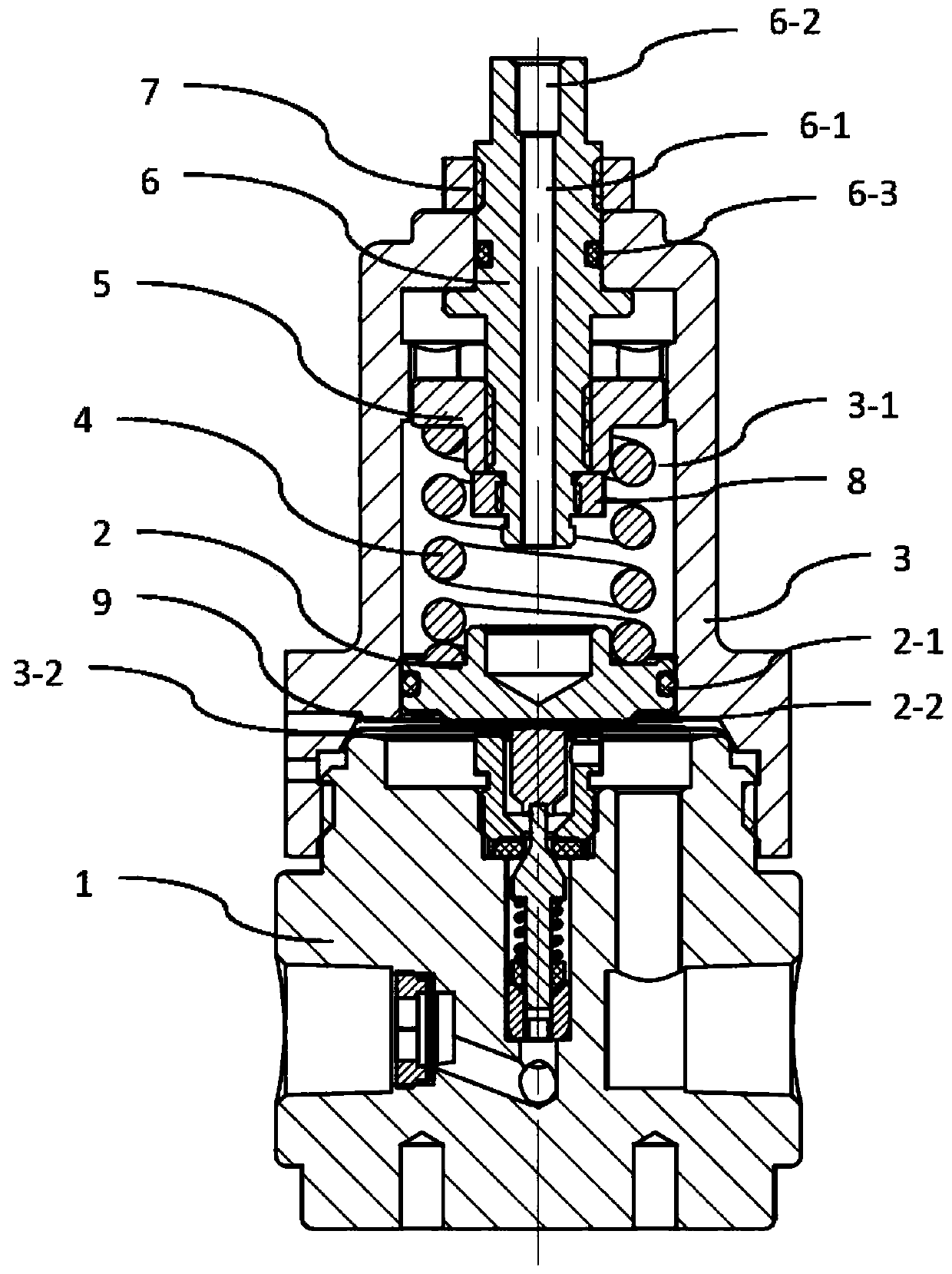

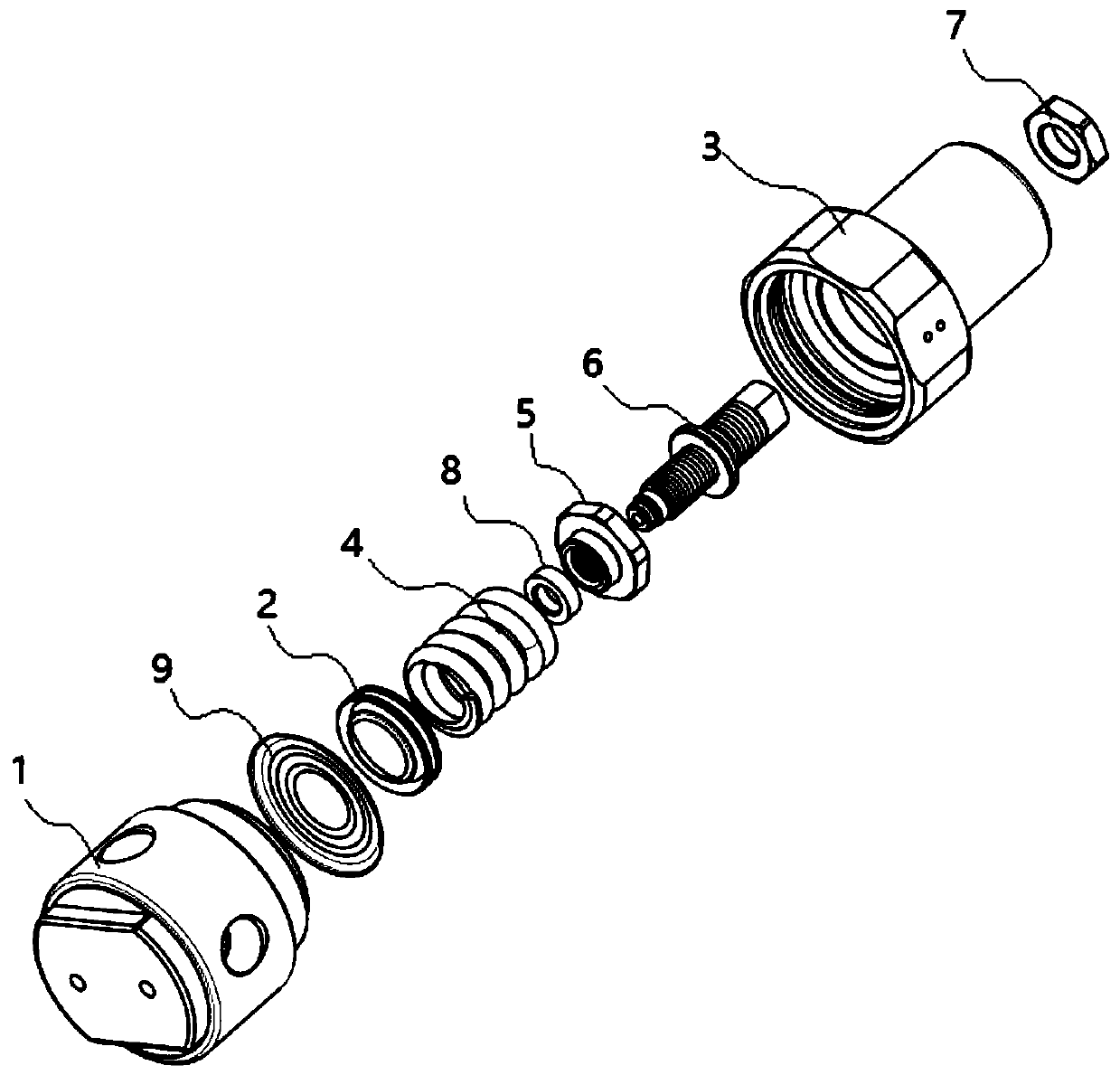

[0025] According to the structural characteristics of the diaphragm pressure reducing valve, a piston structure is added on the diaphragm in the pressure reducing valve, so that a pressure chamber is formed inside the pressure reducing valve, and the pressure of the pressure chamber is converted into a loading force through the piston. At the same time, the diaphragm is protected from the upper side, so that the diaphragm is only subjected to internal pressure and not external pressure, and the internal pressure acts on the piston structure to limit the protection. In this way, even if the diaphragm is broken, the working gas and the control gas are completely isolated, and the two gases do not interfere with each other. The piston acts as a spar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com