Controlled nucleation during freezing step of freeze drying cycle using pressure differential ice crystals distribution from condensed frost

A nucleation and ice crystal technology, applied in the directions of drying gas arrangement, drying, drying machine, etc., can solve problems such as increasing the inhomogeneity between bottles of freeze-dried products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

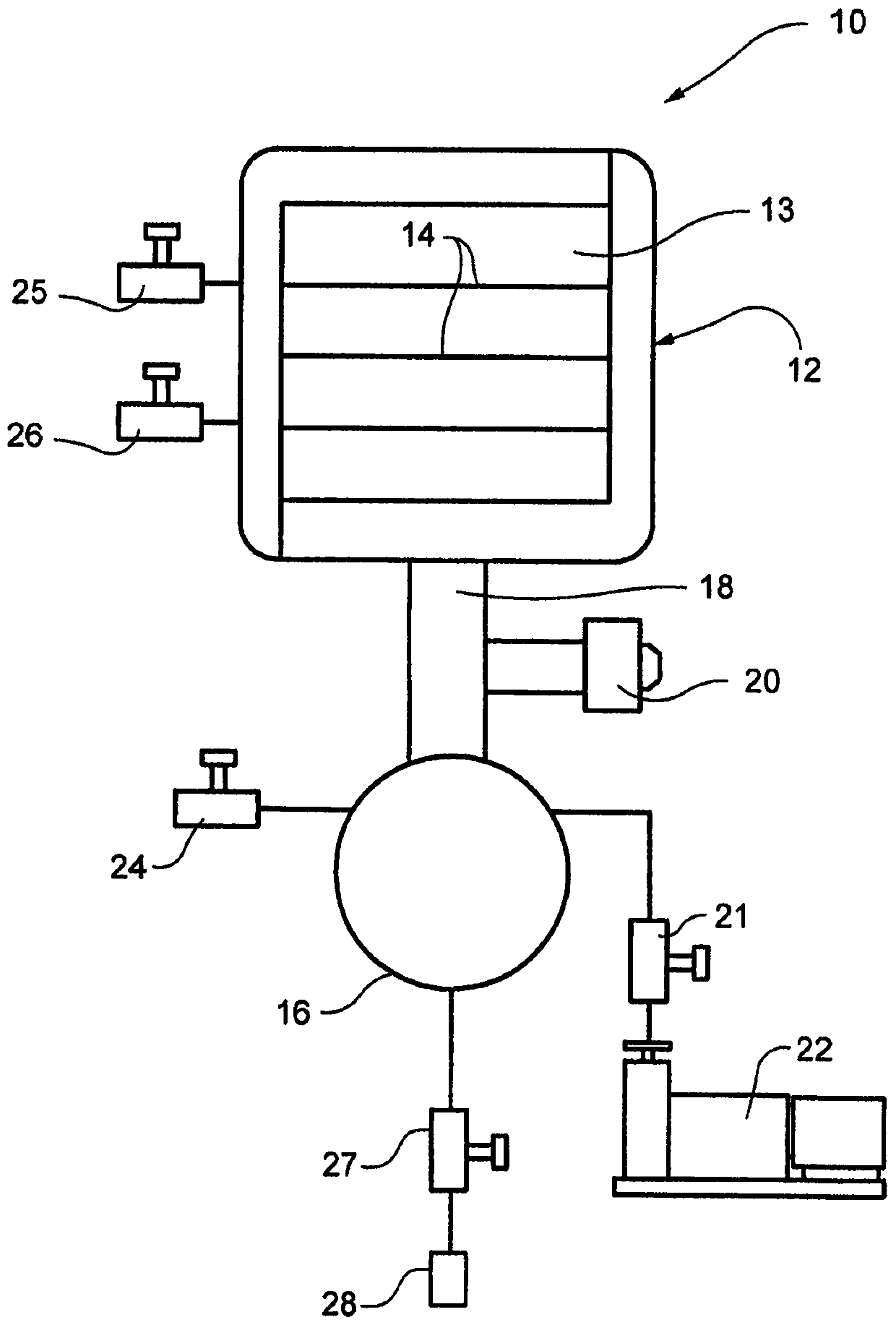

[0021] as in figure 1 As shown, the apparatus 10 for carrying out the method of the present invention comprises a lyophilizer 12 having one or more shelves 14 for supporting vials of product to be lyophilized. The condensation chamber 16 is connected to the lyophilizer 12 through a vapor port 18 having an isolation valve 20 of any suitable configuration between the condensation chamber 16 and the lyophilizer 12 . Preferably, the isolation valve 20 is constructed as a bi-directional sealed vacuum.

[0022] The vacuum pump 22 is connected to the condensing chamber 16 by a valve 21 between them and of any suitable configuration. Condensate chamber 16 has fill valve 24 and vent valve 27 and filter 28 with any suitable structure, and freeze dryer 12 has control valve 25 and release valve 26 with any suitable structure.

[0023] As an illustrative example, the operation of apparatus 10 according to one embodiment of the method of the present invention is as follows:

[0024] 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com