Method and system for measuring flow rate of homogeneous gas-liquid mixed two-phase flow based on ert

A gas-liquid mixing and flow measurement technology, applied in the direction of volume/mass flow, liquid/fluid solid measurement, measurement flow/mass flow, etc. generated by electromagnetic effects, can solve the problems of poor real-time performance, complicated operation and low precision, and achieve The effect of good real-time performance, high measurement accuracy and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] For example, the mechanical seal of a rocket engine, when working in a low-temperature and high-speed environment, the friction will cause two-phase flow in the fluid medium. At this time, the performance of the mechanical seal will change greatly, and the traditional single-phase flow theory is no longer applicable. However, The traditional two-phase flow test technology is cumbersome, the measurement process is troublesome, the result accuracy is low, and the real-time performance is poor. The present invention proposes a homogeneous gas-liquid mixed two-phase flow flow test based on ERT after innovation and research. methods and systems.

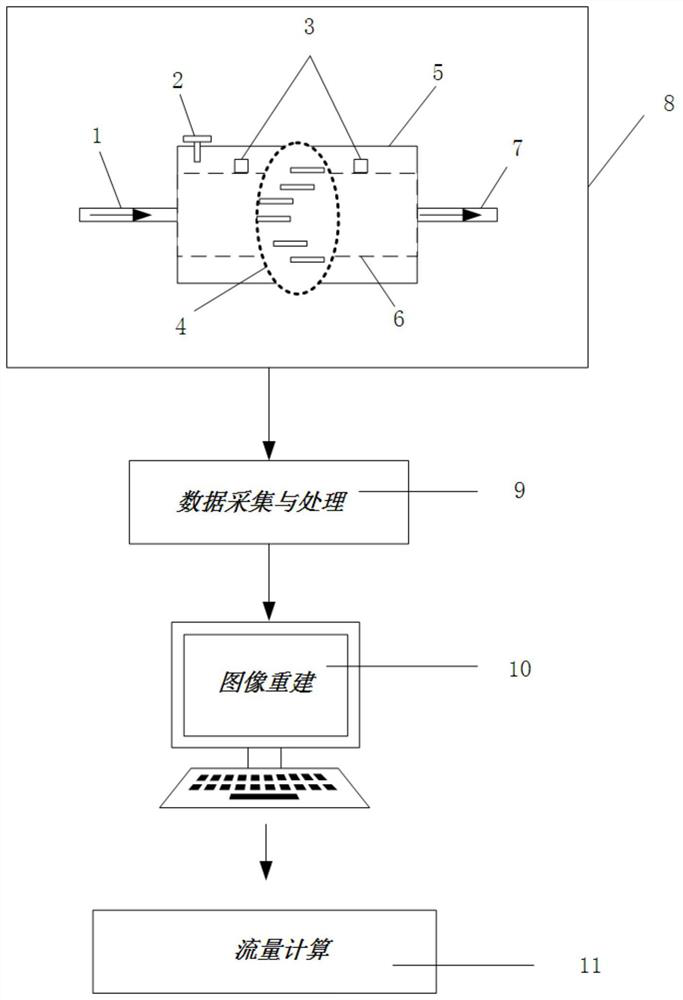

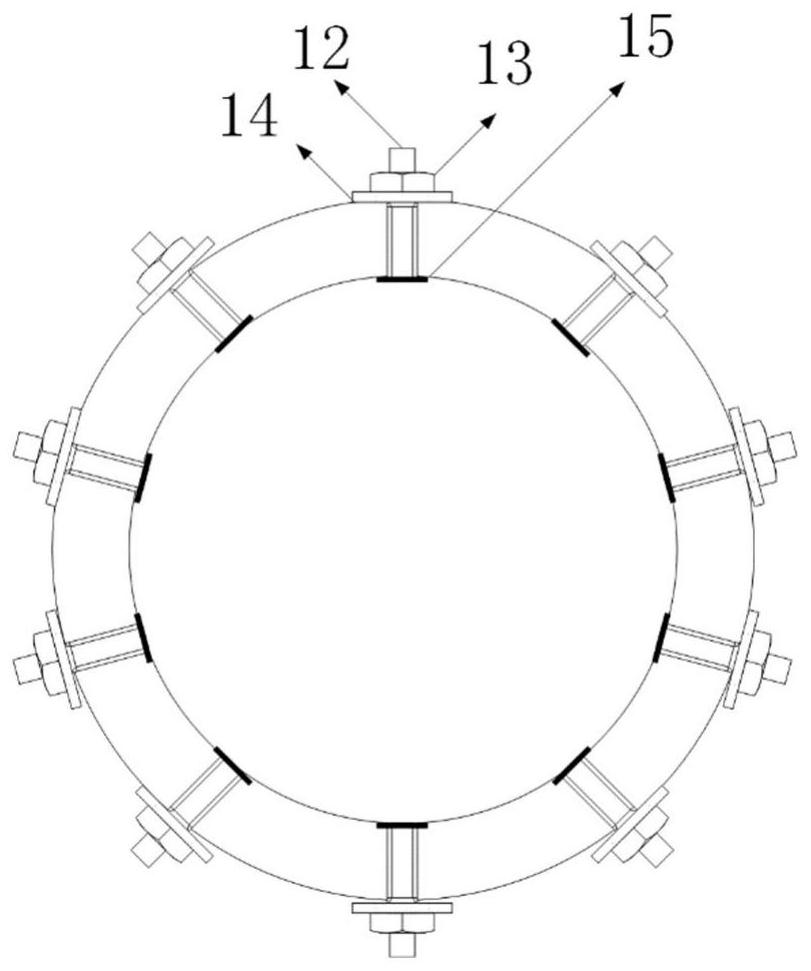

[0029] The invention is an ERT-based flow test method for homogeneous gas-liquid mixed two-phase flow, which defines the liquid phase as a continuous phase and the gas phase as a discrete phase. In the working place where homogeneous gas-liquid mixed two-phase fluid is usually provided with an inlet pipe, a central pipe and an outl...

Embodiment 2

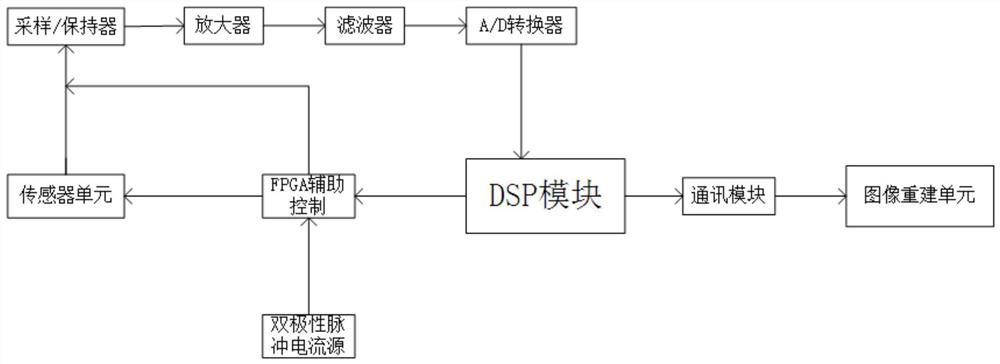

[0037] The homogeneous gas-liquid mixed two-phase flow flow testing method based on ERT is the same as embodiment 1, the RBF (radial basis) neural network described in the step (4) of the present invention, its network structure is a three-layer forward network: input layer, hidden layer and output layer. Among them, there is a nonlinear relationship between the input layer and the hidden layer, and a Gaussian function is used to transform from the input layer to the hidden layer, and the data is mapped to a high-dimensional space, and there is a linear relationship between the hidden layer and the output layer. The input is multiple sets of voltage data reflecting the gas-liquid mixed two-phase flow pattern measured by the electrode array. After the voltage data preprocessing, training, verification, testing, and image filling steps, the output is the reconstructed two-phase flow pattern image. . The present invention uses RBF (radial basis) neural network to reconstruct the...

Embodiment 3

[0039] The ERT-based homogeneous gas-liquid mixed two-phase flow flow test method is the same as that of Embodiment 1-2, and the flow calculation described in step (5) of the present invention is specifically the flow calculation method of the homogeneous gas-liquid mixed two-phase flow:

[0040] (5.1) Calculation of continuous phase (liquid phase) flow q 1 =s·(1-α)·v; where s is the area of the sensitive field (cross-sectional area of the inner pipe), and α is the mixing ratio, that is, the ratio of the discrete phase (gas phase) to the area of the sensitive field (cross-sectional area of the inner pipe), v is the velocity of homogeneous gas-liquid mixed two-phase flow.

[0041] (5.2) Calculate the discrete phase (gas phase) flow rate q 2 =s·α·v; where s is the area of the sensitive field (cross-sectional area of the inner pipe), α is the mixing ratio, that is, the ratio of the discrete phase (gas phase) to the area of the sensitive field (cross-sectional area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com