Atomic force microscope real-time drift compensation system and method based on vision sensing

An atomic force microscope and visual sensing technology, applied in scanning probe microscopy, measuring devices, instruments, etc., can solve problems that cannot be eliminated, complex structures, and narrow probe operation space, and achieve high-precision measurement and compensation, The effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings.

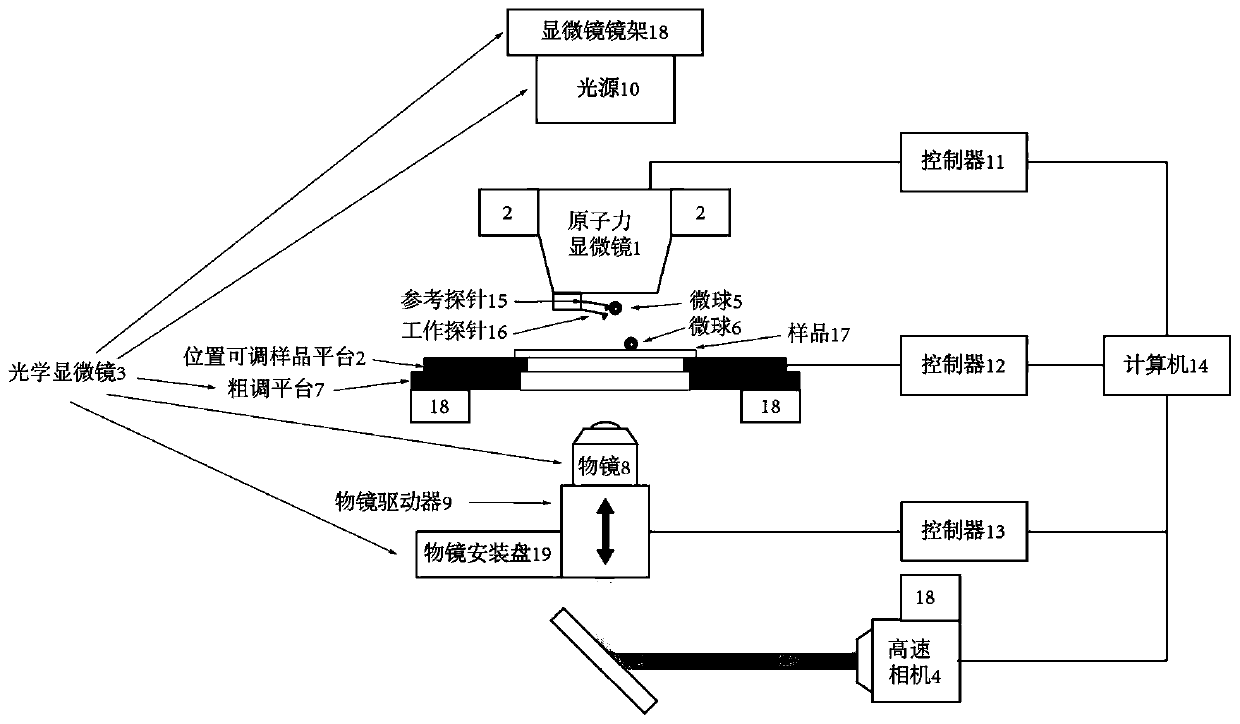

[0017] The real-time drift compensation system of the atomic force microscope based on visual sensing of the present invention mainly includes an atomic force microscope 1, a position-adjustable sample platform 2, an optical microscope 3, a high-speed camera 4, a microsphere 5, a microsphere 6, a rough adjustment platform 7, and an objective lens 8 , objective lens driver 9, light source 10, controller 11, controller 12, controller 13, computer 14, reference probe 15, working probe 16, sample 17, microscope frame 18, objective lens mounting plate 19. Wherein, the coarse adjustment platform 7 , the objective lens 8 , the light source 10 , the microscope frame 18 and the objective lens mounting plate 19 are the components of the optical microscope 1 .

[0018] Wherein, the light source 10 provides a light field of appropriate intensity for the system, and is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com