Train phase separation passing converter

A technology of over-phase splitting and converters, applied in the field of over-phase splitting, can solve problems such as difficulty in governance and cost of governance, asymmetric distribution of three phases, and impact on normal operation of trains, etc., to improve auxiliary heat dissipation performance, improve heat dissipation performance, and facilitate The effect of assembling extensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

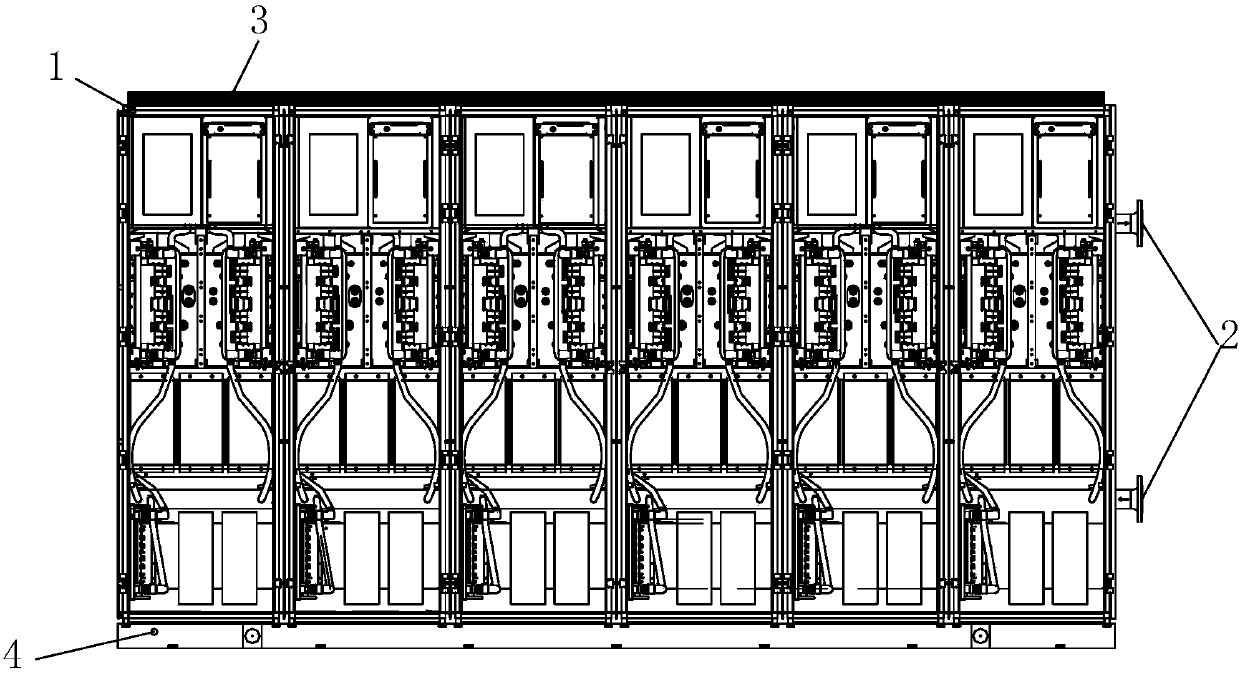

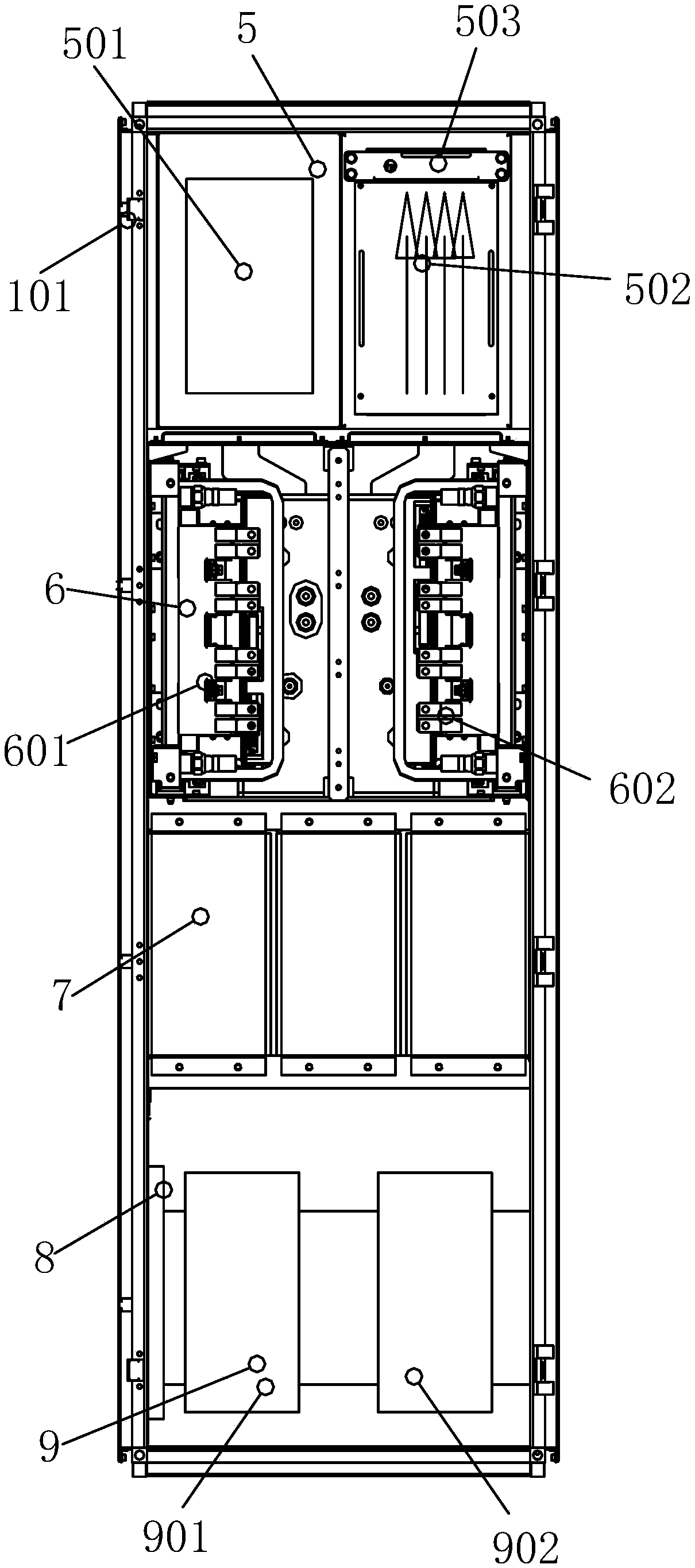

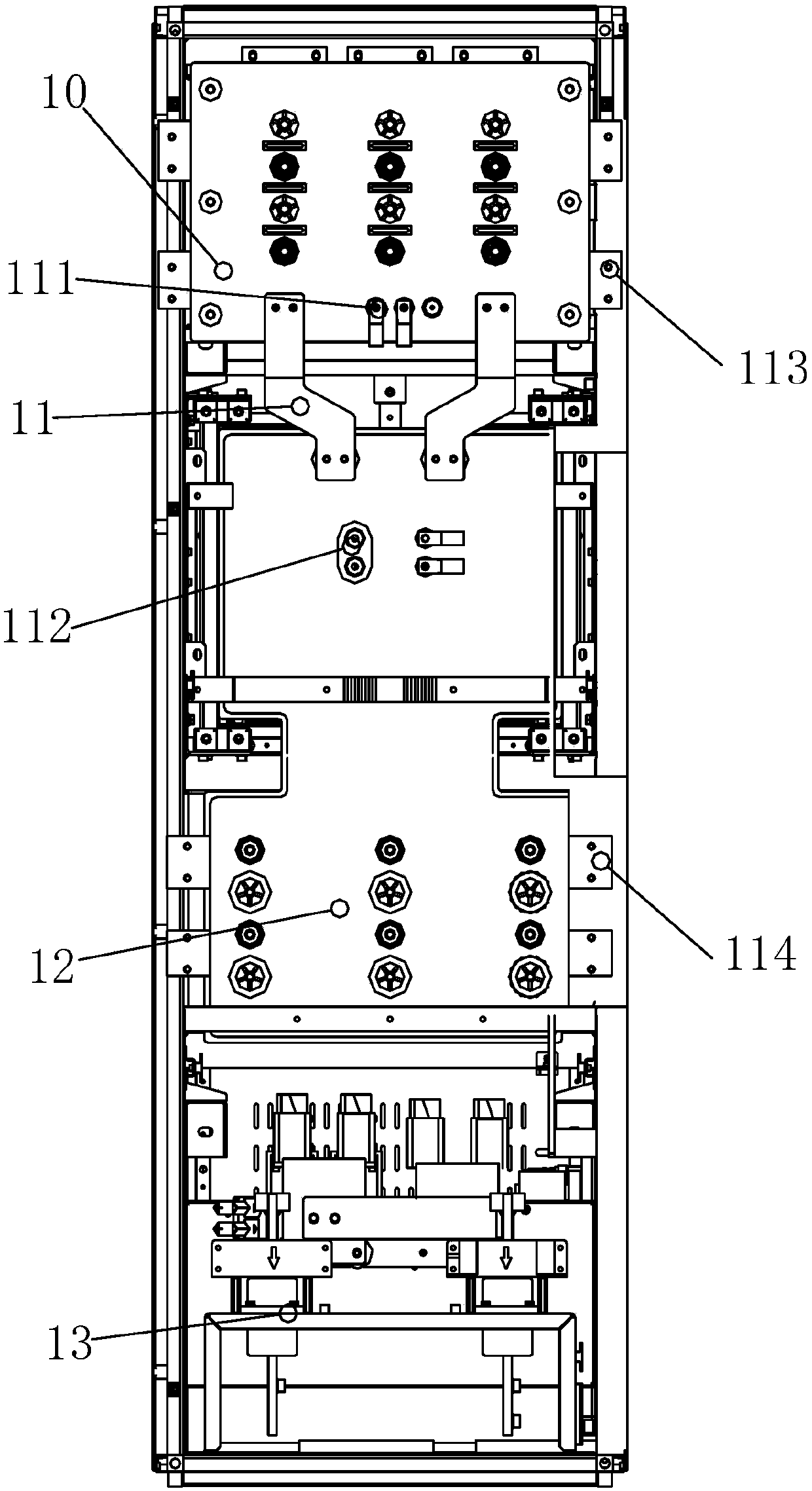

[0031] Such as Figure 1 to Figure 8 As shown, the train over-phase converter of this embodiment includes a base 4 and a plurality of unit cabinets 1, and a plurality of unit cabinets 1 are installed side by side on the base 4, and each unit cabinet 1 has the same structure; the unit cabinet 1 includes a cabinet body 101. Electric control component 5, power module component 6, support capacitor 7, discharge resistor component 8, contactor component 9, resonant capacitor 14 and wiring component 13; cabinet 101 is provided with multiple support beams 103, electric control component 5 , the power module assembly 6, the support capacitor 7 and the contactor assembly 9 are installed on the support beam 103 of the cabinet 101 from top to bottom, the resonant capacitor 14 is installed side by side with the electric control assembly 5 and is located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com