A split-and-hanging wire-type walking clamping mechanism for transmission line inspection robots

A technology for inspection robots and power transmission lines, which is applied in the directions of overhead lines/cable equipment, manipulators, manufacturing tools, etc., can solve the problems of lateral offset distance and complex obstacle-crossing methods of line inspection robots, and achieves reduction of lateral offset distance, The effect of simplifying the way of crossing obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

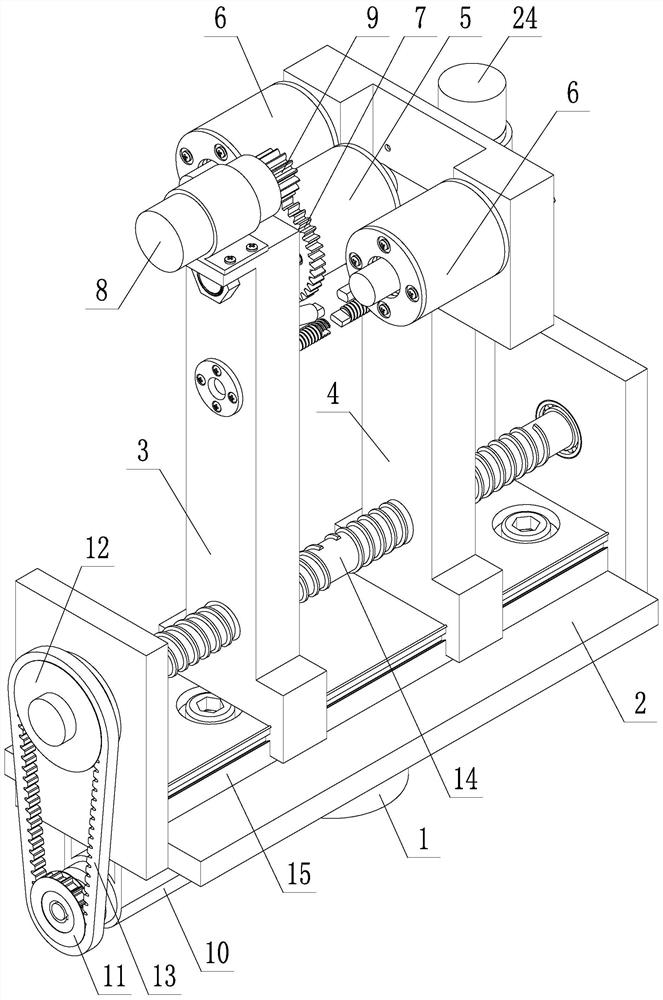

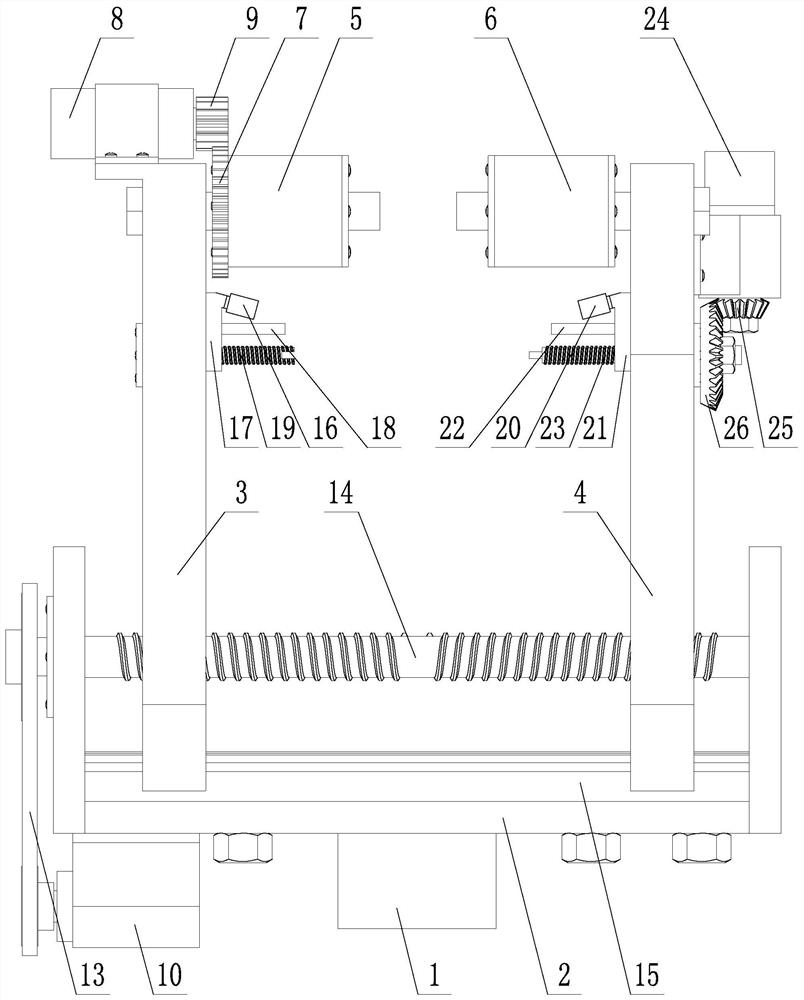

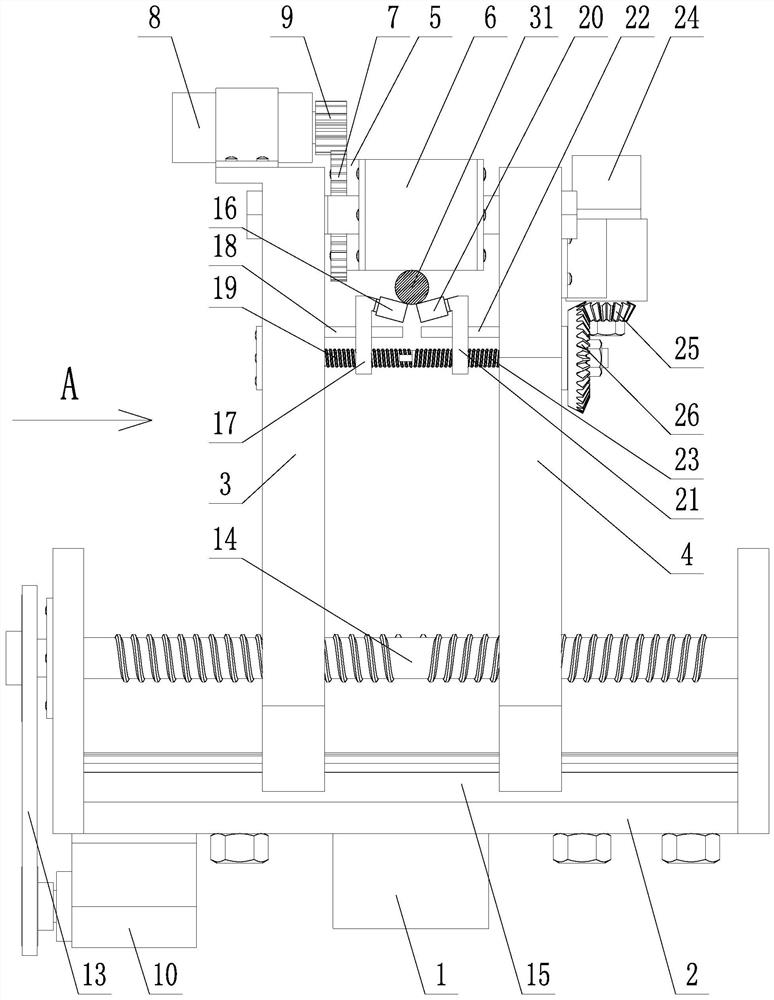

[0020] like Figures 1 to 6 As shown in the figure, a split-line-type walking and clamping mechanism for a power transmission line inspection robot includes an arm joint 1, a base 2, a first pillar 3, a second pillar 4, an active traveling wheel 5 and a driven traveling wheel 6; The arm joint 1 is fixedly mounted on the bottom of the base 2, and the first pillar 3 and the second pillar 4 are vertically installed on the base 2; A driven gear 7 is fixed on the wheel 5; a walking drive motor 8 is arranged on the top of the first support 3, and a driving gear 9 is installed on the motor shaft of the walking driving motor 8, and the driving gear 9 is in phase with the driven gear 7. Meshing; the number of the driven running wheels 6 is two, the two driven running wheels 6 are horizontally installed on the upper end of the second pillar 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com