Flat battery and electronic device

A technology for plate-shaped batteries and battery cores, applied in battery circuit devices, batteries, small flat batteries/batteries, etc., can solve the problems of complex sealing structure, unstable potential, weak bonding, etc., and achieve improved mechanical strength and improved Adhesive strength, easiness of potential fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

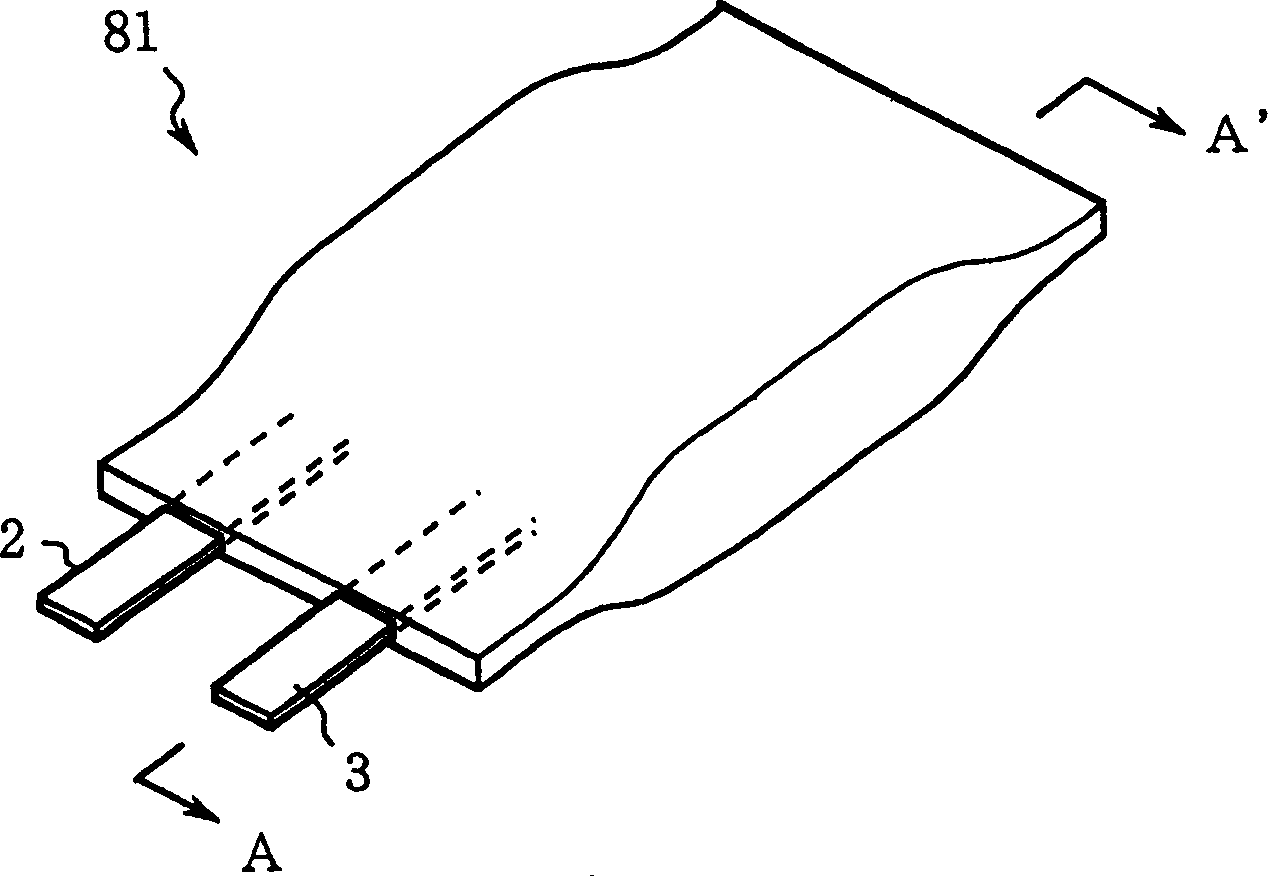

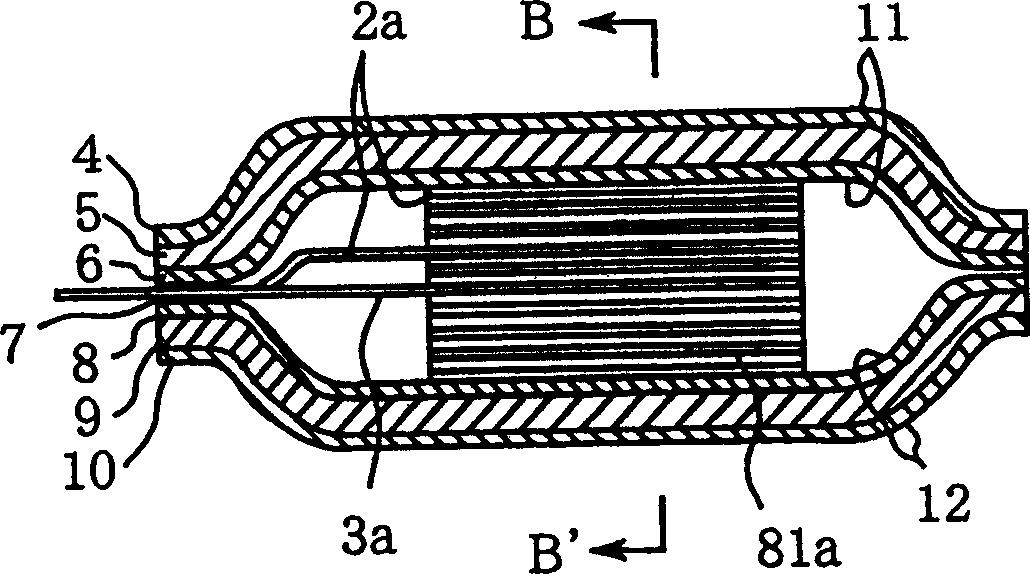

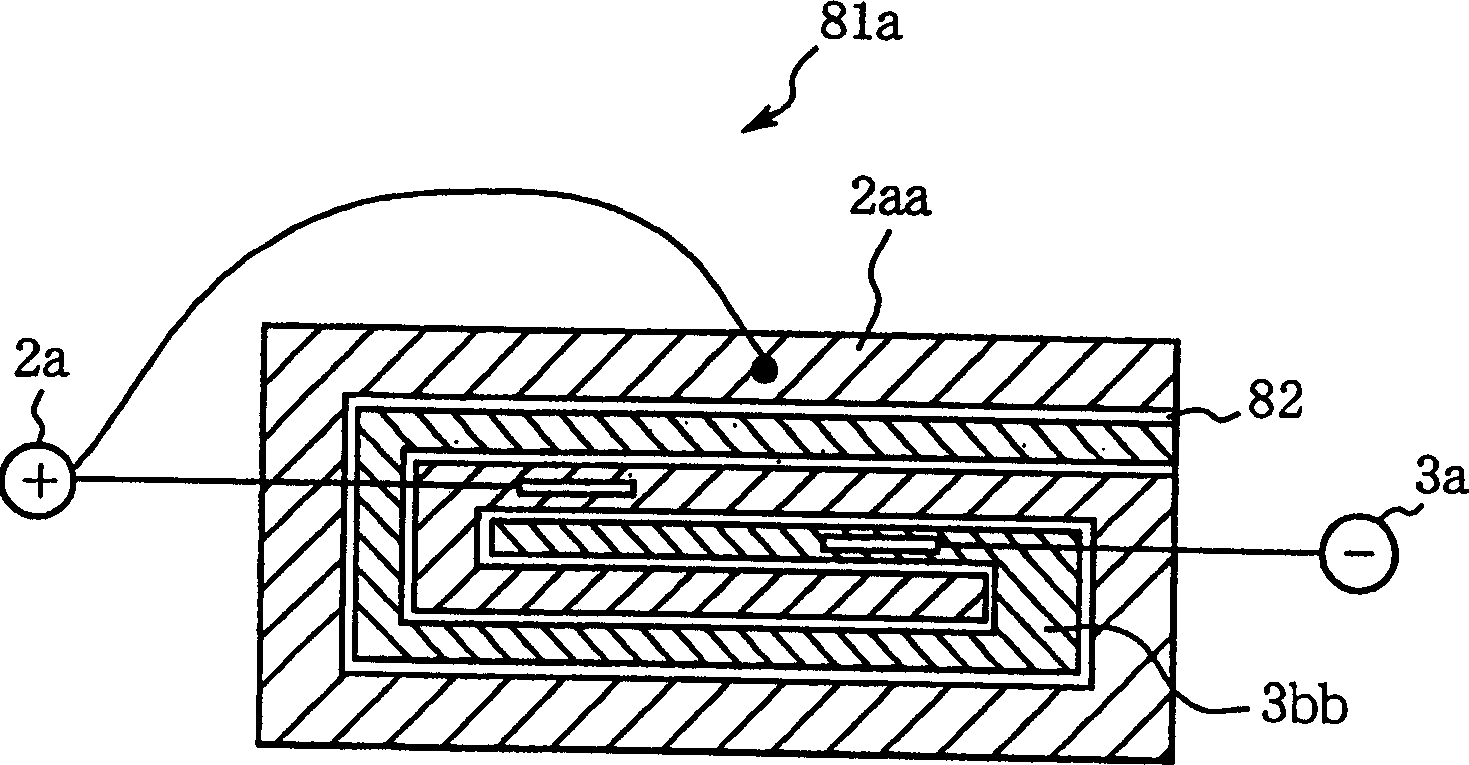

[0097] Figure 4 It is a perspective view showing a plate-shaped battery capable of replenishing or releasing battery energy, such as a nickel-cadmium battery, a nickel-metal hydride battery, and a lithium-ion battery formed in Embodiment 1 of the present invention, Figure 5 is along Figure 4 The cross-sectional view taken on the line C-C', Figure 6 is along Figure 4 Cross-sectional view taken along line D-D'.

[0098] 1 in the figure is a thin plate-shaped battery formed of nickel-cadmium batteries, nickel-hydrogen batteries, lithium-ion batteries, etc., 1a is a battery core, which is used as an internal battery of the plate-shaped battery 1; 21, 20 are positive electrode leads and negative electrode leads, They serve as the input and output terminals of the plate-shaped battery 1; 4, 10 are polymer resins such as polyethylene, polypropylene, polyethylene terephthalate; 5, 9 are metal foils made of metal materials such as aluminum; 11 is a skin sheet that is laminated w...

Embodiment approach 2

[0112] Figure 9 It is a cross-sectional view showing a plate-shaped battery formed in Embodiment 2, which corresponds to the case of the lamination structure shown in the outer skin sheets 11 and 12 described in Modification 2. In the figure, 101 is a connecting portion formed by the positive electrode lead 21 on the extraction hole 19 and a conductor such as the metal foil 5 in the laminated film. Naturally, the negative electrode 20 side also adopts the same structure.

[0113] Below, refer to Figure 9 On the lead wire 21, until the surface of the lead wire is exposed, the outer skin sheet 11 constituting the casing on the box-type electrode is opened to form a take-out hole 19, and the connecting portion 101 is formed here, and is welded, contacted, and the like. The lead wires 21 are electrically connected to the metal foil 5 in the skin sheet 11 forming the laminated film. Therefore, the electric energy input or output of battery, can not be taken out from the box-ty...

Embodiment approach 3

[0117] Figure 10 is a perspective view showing a plate-shaped battery formed in Embodiment 3 of the present invention, Figure 11 is along Figure 10 The cross-sectional view taken along the E-E' line. Among the figure, 16 is on the sheath sheet 11,12 that is electrically connected with positive electrode 21, leads such as aluminum from metal foil 5,9; 23 is the metal foil in laminated film, is to extend from metal foil 5,9 to the side of the housing.

[0118] If the plate-shaped battery 1 formed in Embodiment 3 is used, as Figure 10 As shown, when the metal foils 5, 9 in the laminated film are connected with the positive electrode lead 21 drawn out from the battery core 1a by means of the lead wire 16, it is outside the case, not inside the battery case, and the lead out of the case is drawn out. The L-shaped metal foil 16 is electrically connected to the positive electrode lead 21 . This connecting portion is a position where the position of the metal foil 16 such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com