A method and system for treating waste rubber based on adding alkali

A technology of alkali treatment and lye solution, applied in sustainable manufacturing/processing, rayon recycling, final product manufacturing, etc., can solve the problems of unfavorable environmental protection and high cost, and achieve the effect of increasing the amount of recycling, reducing operating costs, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

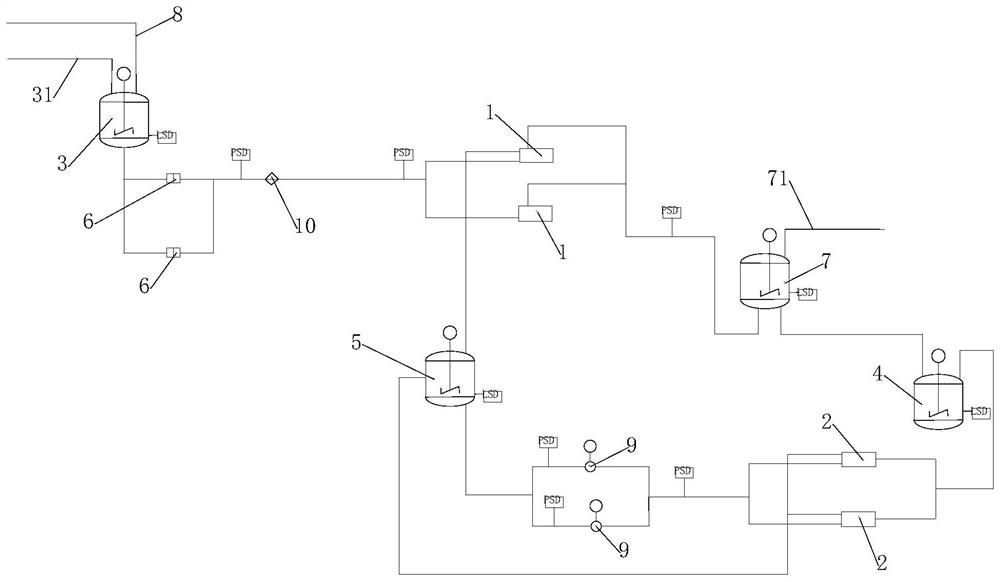

[0037] A kind of method of processing waste rubber based on adding alkali of the present embodiment specifically comprises the following steps:

[0038] S1, input the waste glue into the waste glue tank 3 through the lye delivery pipeline and stir to obtain the self-assembled dispersion Ⅰ. Fiber blocks, short fibers and flocs of different lengths can be seen under the microscope, and the glue is turbid;

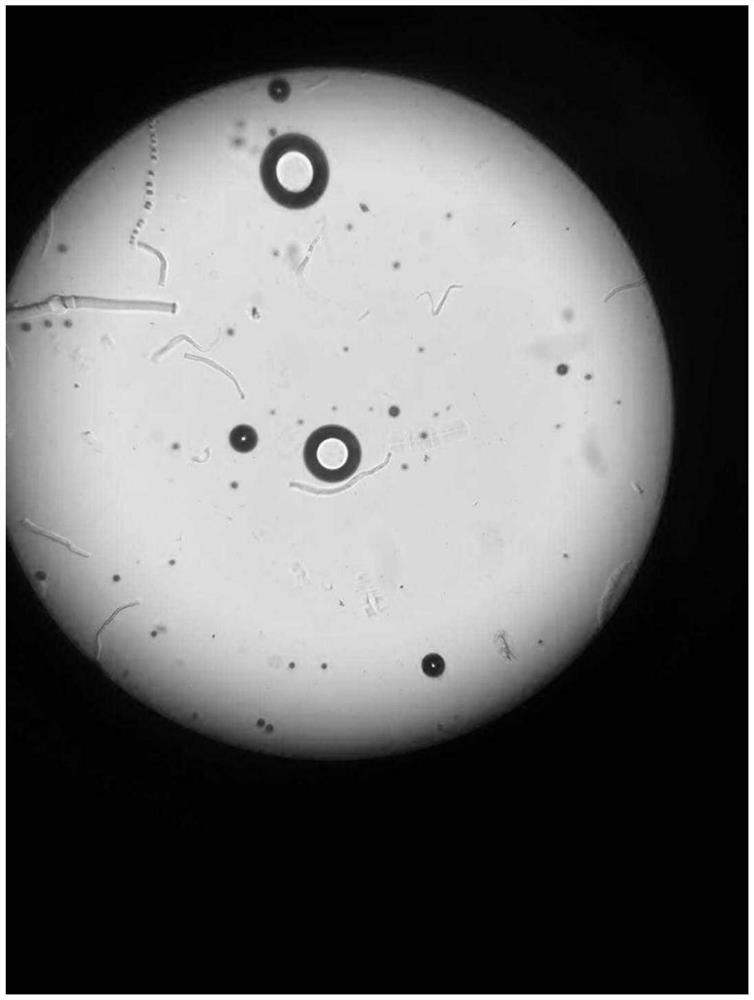

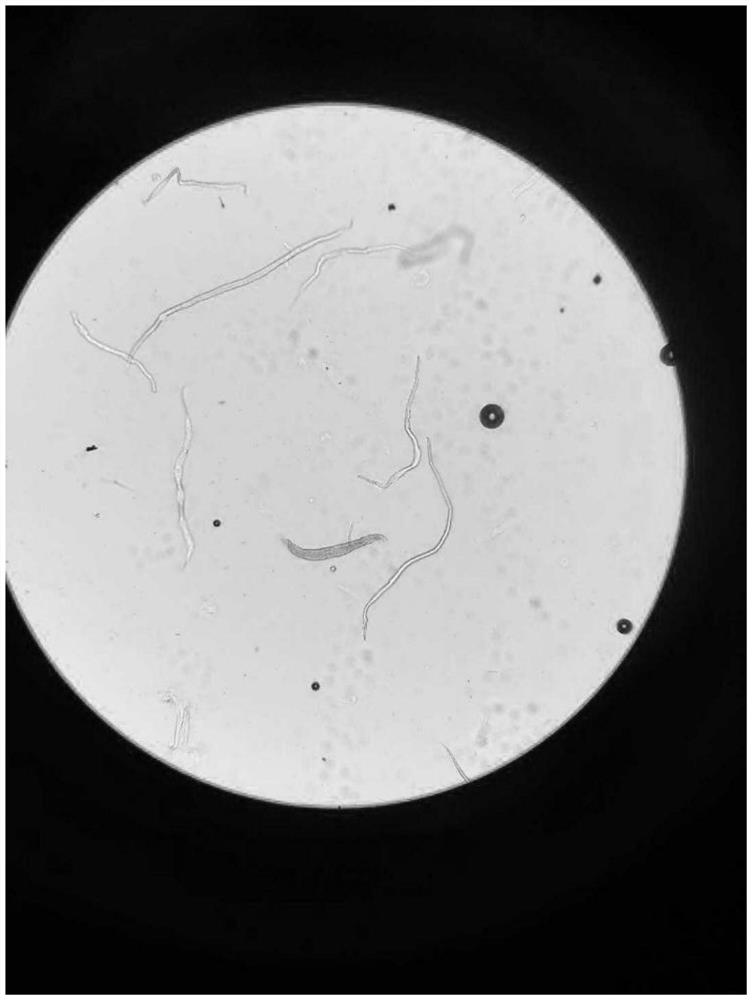

[0039] S2, adding high-concentration lye to the self-assembly dispersion I and stirring to obtain the self-assembly dispersion II, observing under a microscope that the fiber blocks, short fibers of different lengths and flocs dissolve rapidly, and the glue is clear; figure 2 as shown, figure 2 It is the breaking condition of cellulose under high-concentration lye (above 140g / L); image 3 It is the condition of cellulose breakage under low concentration of lye (below 140g / L). Compared figure 2 and image 3 It can be seen that the use of high-concentration lye can make ...

specific Embodiment approach 1

[0046] A method for treating waste rubber based on adding alkali, comprising the following steps:

[0047] S1, input the waste rubber into the waste rubber tank and stir, the stirring speed is 20rmp, and the stirring time is 15min, to obtain the self-assembly dispersion I;

[0048] S2, adding a sodium hydroxide solution with a concentration of 450g / L to the self-assembly dispersion I and stirring, the stirring speed is 20rmp, and the stirring time is 15min to obtain the self-assembly dispersion II; the self-assembly dispersion The concentration of II is 140g / L. The volume ratio of the self-assembly dispersion I to the lye is 3:0.8.

[0049] S3, filtering the self-assembly dispersion II.

specific Embodiment approach 2

[0051] A method for treating waste rubber based on adding alkali, comprising the following steps:

[0052] S1, input the waste rubber into the waste rubber tank and stir, the stirring speed is 22rmp, and the stirring time is 20min, to obtain the self-assembly dispersion I;

[0053] S2, adding a sodium hydroxide solution with a concentration of 430g / L to the self-assembly dispersion I and stirring, the stirring speed is 22rmp, and the stirring time is 20min to obtain the self-assembly dispersion II; the self-assembly dispersion The concentration of II is 150g / L. The volume ratio of the self-assembly dispersion I to the lye is 3:0.9.

[0054] S3, filtering the self-assembly dispersion II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com