A cross-sectional rock formation sampling device for studying biofossil belts

A biofossil and sampling device technology, applied in the field of geological exploration equipment, can solve the problems that cannot satisfy the research of biofossil belts, and achieve the effects of reducing vibration, ensuring integrity, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

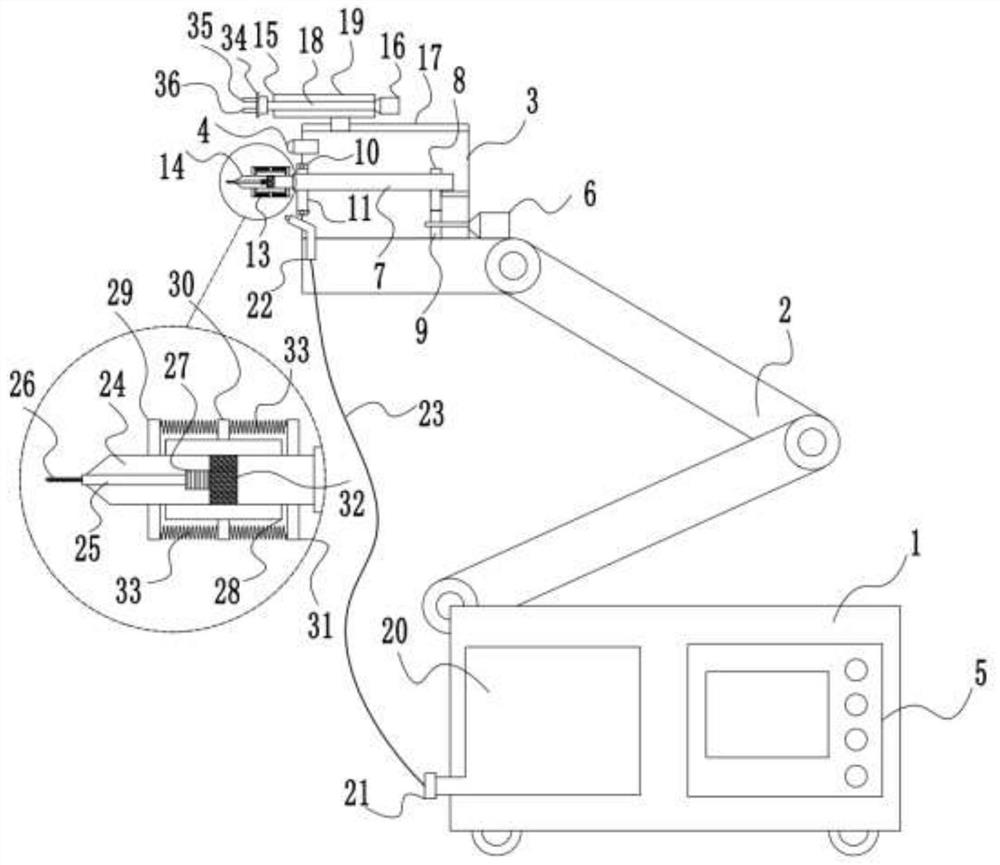

[0036] Such as figure 1 As shown, a section rock sampling device for studying biofossil belts includes a base 1, an elevating ladder 2 and a box 3 arranged on the top of the elevating ladder 2, and a power drive mechanism, a drilling mechanism, The sampling mechanism and the visual sensor 4, the base 1 is equipped with a display controller 5 electrically connected to the power drive mechanism, the drilling mechanism, the sampling mechanism and the navigation mechanism; the visual sensor 4 is arranged in front of the box body 3 between the drilling mechanism and the sampling mechanism on the side. Vision sensor 4 is a commercially available product, optional

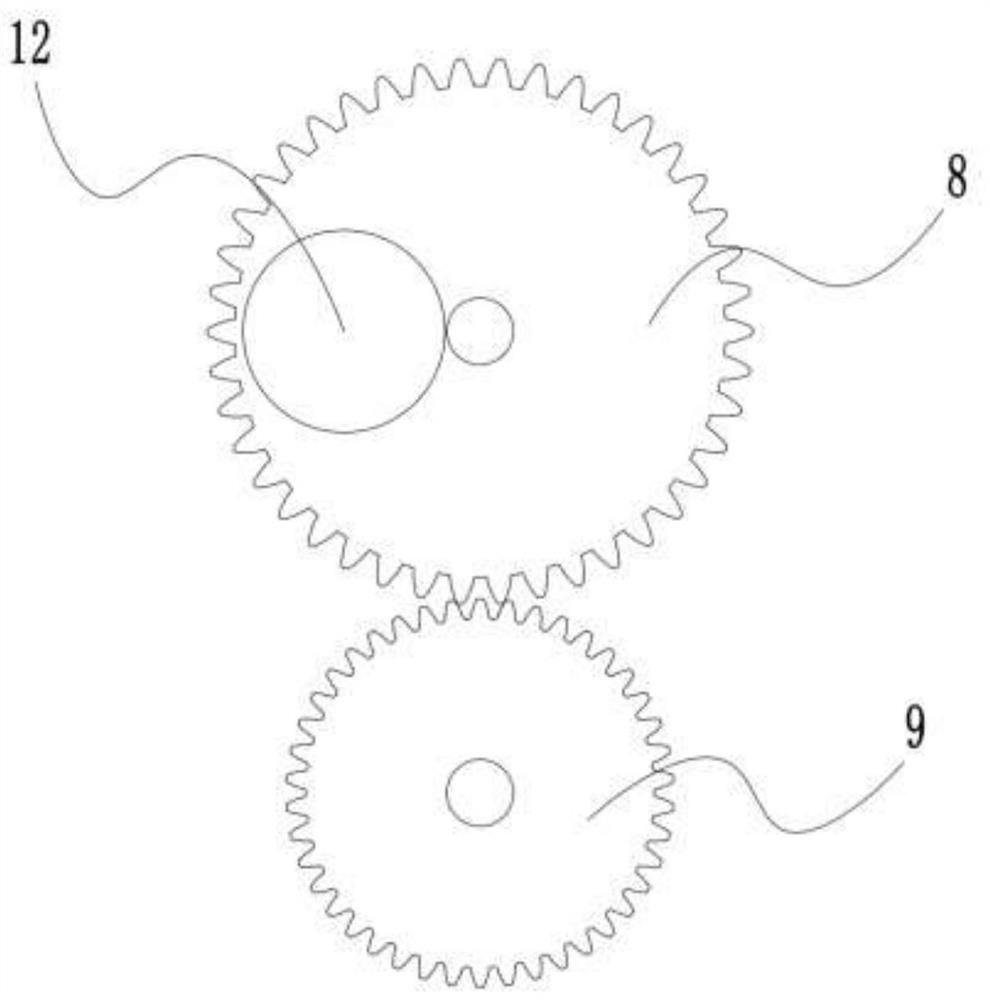

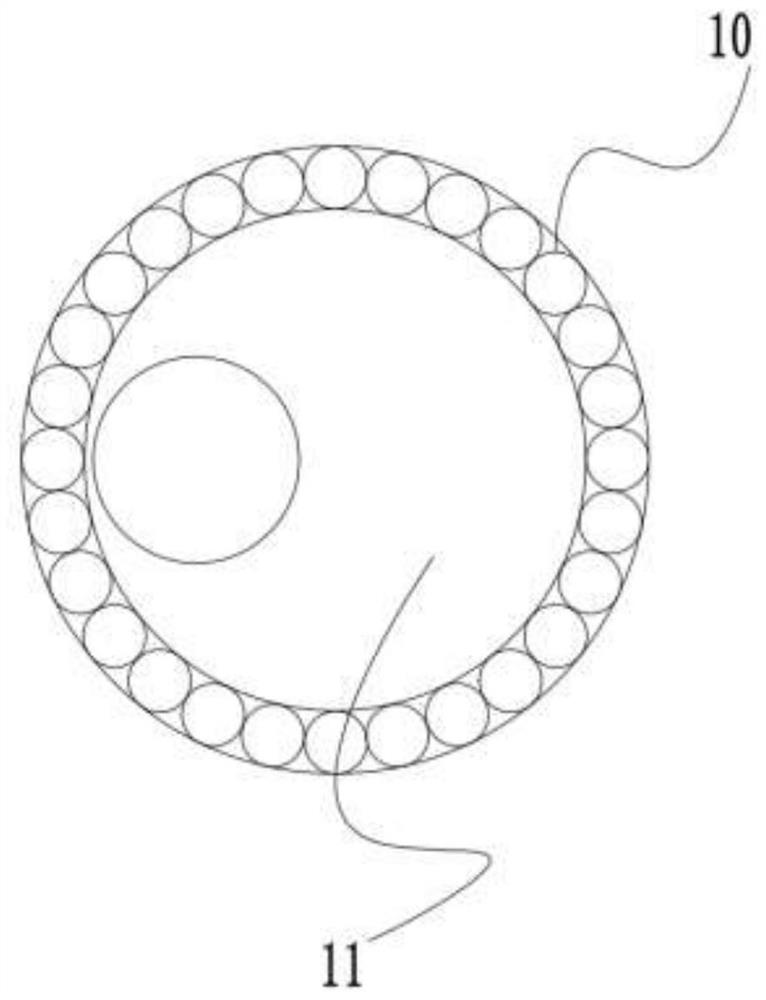

[0037] Such as figure 1 As shown, the power drive mechanism includes a drive motor 6, an electrohydraulic rod 7, a large gear 8, a pinion 9, and a rotary bearing 10. On the side wall of the box body 3, such as image 3 As shown, a turntable 11 is installed in the rotating bearing 10, and the pinion 9 is installed at t...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, the difference is:

[0048] (1) The drill bit 26 is a twist drill, the diameter of the drill bit 26 is 8 mm, and the length is 15 cm.

[0049] (2) if Figure 5 As shown, the pre-tightening buffer mechanism 32 includes a buffer rubber hemisphere 1 38, a buffer rubber hemisphere 2 39 and a connecting spring 40. 40 is connected between the interiors of buffer rubber hemisphere one 38 and buffer rubber hemisphere two 39. The two planar ends of buffer rubber hemisphere 1 38 and buffer rubber hemisphere 2 39 are in close contact with the hollow drill barrel 24 rear end of small electric drill 14 and the front end of electro-hydraulic rod 7, and the knob can be fully screwed up. Can also play the effect of anti-slip and anti-loosening, the spherical surfaces of buffer rubber hemisphere 1 38 and buffer rubber hemisphere 2 39 are opposite, which can improve the buffer space, and connecting spring 40 is used to play the eff...

Embodiment 3

[0053] This embodiment is basically the same as Embodiment 1, the difference is:

[0054] (1) The drill bit 26 is a twist drill, the diameter of the drill bit 26 is 9 mm, and the length is 17 cm.

[0055] (2) In S2, the electrohydraulic rod 7 advances at a constant speed at a feed rate of 30 cm / min.

[0056] (3) In S3, the drill bit 26 is driven by the electro-hydraulic rod 7 while maintaining its rotation and at the same time moves at a circumferential speed of 30 cm / min until it connects hole A to hole D.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com