Preparation method of reversed polarity AlGaInP quaternary LED chip

A technology of LED chips and LED epitaxial wafers, applied in the field of optoelectronics, can solve the problems of low output matching rate, unstable process, long manufacturing process of quaternary LED chips, etc., and achieve high matching rate and high matching rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a reverse polarity AlGaInP quaternary LED chip, comprising:

[0041] (1) Prepare the P-side ohmic contact layer and the current blocking layer sequentially on the P-side of the reverse polarity AlGaInP quaternary LED epitaxial wafer by conventional methods; the reverse polarity AlGaInP quaternary LED epitaxial wafer includes the GaAs substrate sequentially from bottom to top , barrier layer GaInP, opaque epitaxial layer, N-type AlGaInP layer, reverse polarity quaternary LED epitaxial layer;

[0042] (2) The epitaxial wafer generated in step (1) is bonded to a single crystal conductive Si substrate or a sapphire substrate by a conventional bonding process;

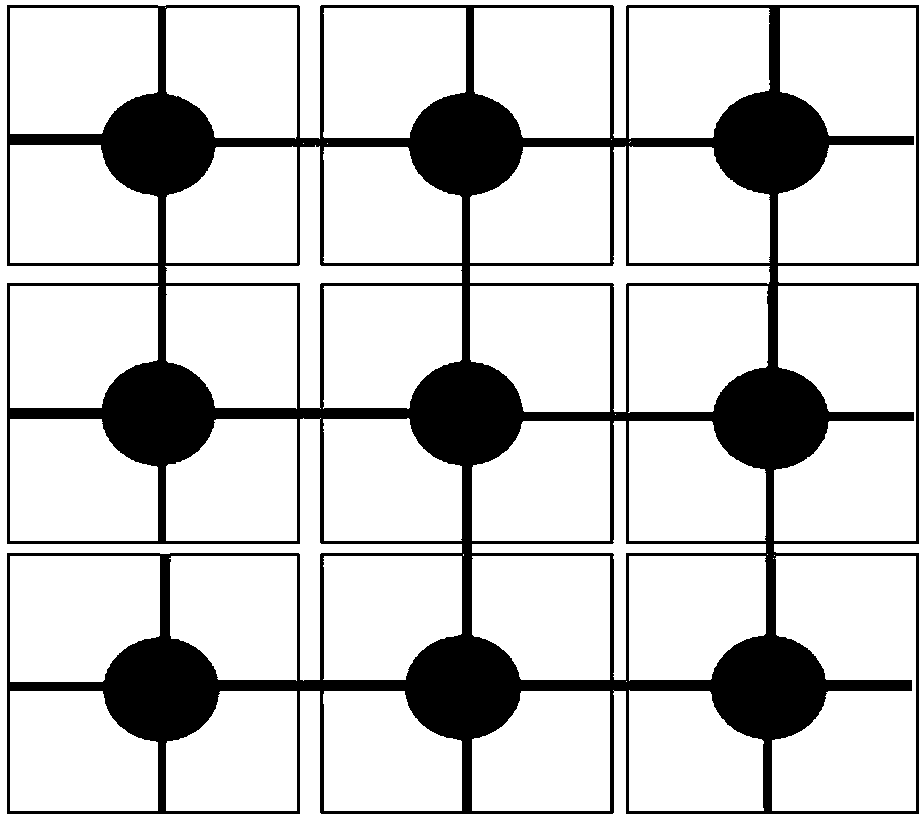

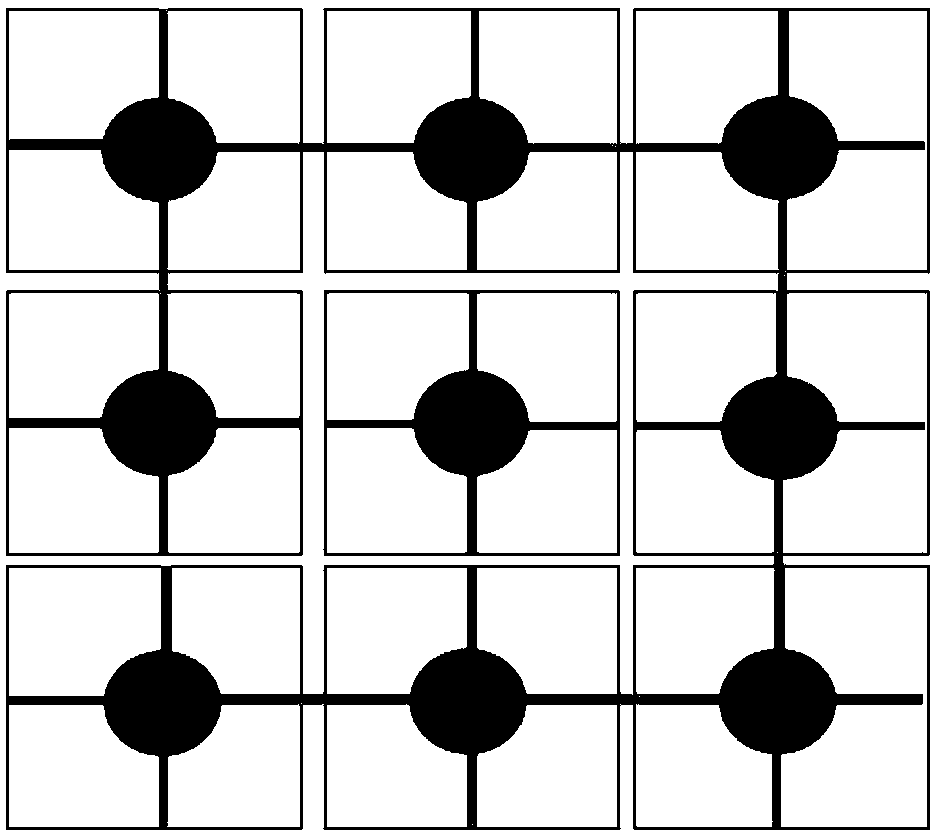

[0043] (3) Use a conventional GaAs substrate etching solution to etch and remove the GaAs substrate, use a conventional GaInP etching solution to etch away the epitaxially grown barrier layer GaInP, and prepare an N-side ohmic contact electrode pattern on the opaque epitaxial layer, and the N-s...

Embodiment 2

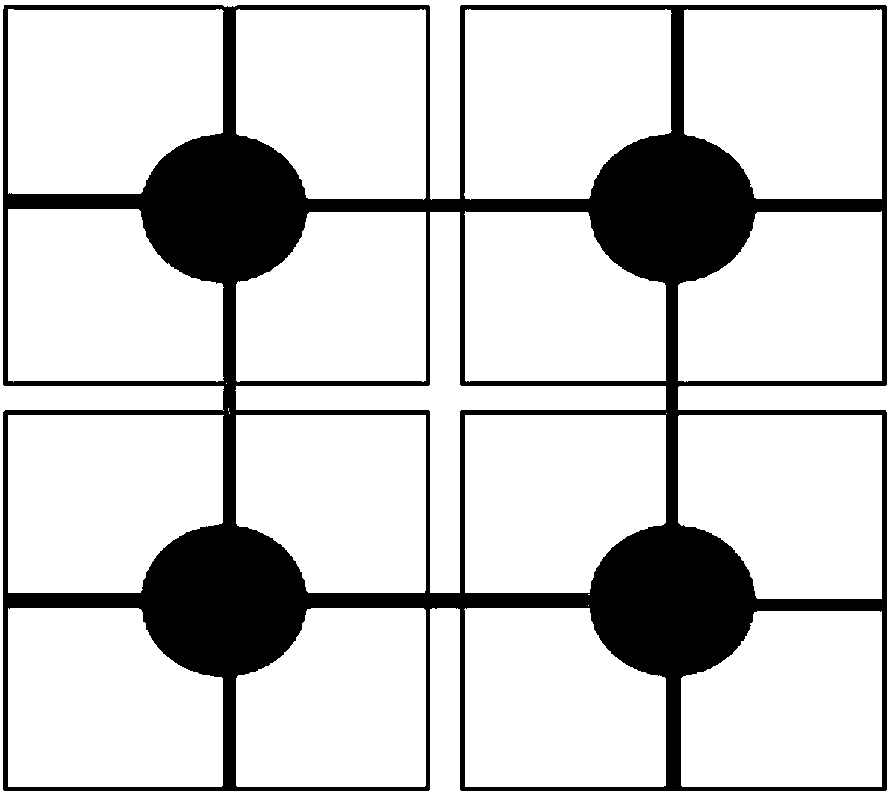

[0056] According to the method for preparing a reverse polarity AlGaInP quaternary LED chip described in Example 1, the feature is that the interval period between the centers of two adjacent small units is 80-150 μm. The width of the linear electrode pattern is 8-15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com