Tobacco sheet filter stick, composite filter stick and manufacturing method thereof

A technology of tobacco sheet and manufacturing method, applied in directions such as tobacco, smoke oil filter element, application, etc., can solve the problems of not mentioning the technology of compound connection of tobacco fiber and acetate fiber, and the undisclosed problem, and achieves low environmental temperature and humidity requirements, reducing Miscellaneous, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

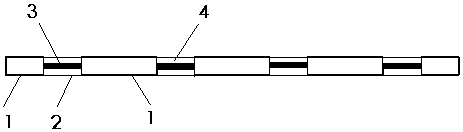

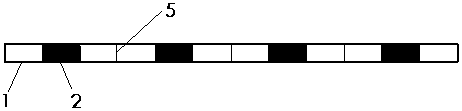

[0041] Such as figure 1 The tobacco sheet composite filter rod shown has a filter element made of tobacco sheet, and the tobacco sheet is a paper sheet made of pulp containing tobacco fiber and acetate fiber, and the pulp may contain wood fiber. The tobacco fiber or wood fiber is treated with lignin peroxidase preparation.

[0042] The ends of some of the tobacco fibers are bonded to the ends of some of the acetate staples.

[0043]Tobacco flake filter element or filter rod is cut into slices containing tobacco flakes in the axial direction, and then spliced together in the axial direction with the filter slices containing tobacco flakes and ordinary cigarettes, and wrapped with the same forming paper around the periphery.

[0044] The manufacturing method of the tobacco sheet filter rod has the following process steps:

[0045] 1) Swelling treatment: Soak the short filaments of cellulose acetate in a small amount of acetone or acetic acid solvent to make the cellulose ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com