Heating device for heat-not-burn smoking set

A heat-not-burn and heating device technology, which is applied in applications, tobacco, and smoker supplies, can solve problems such as uneven heating, large power consumption, and inconvenient operation, and achieve improved battery use efficiency, high power conversion efficiency, and convenience. The effect of cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

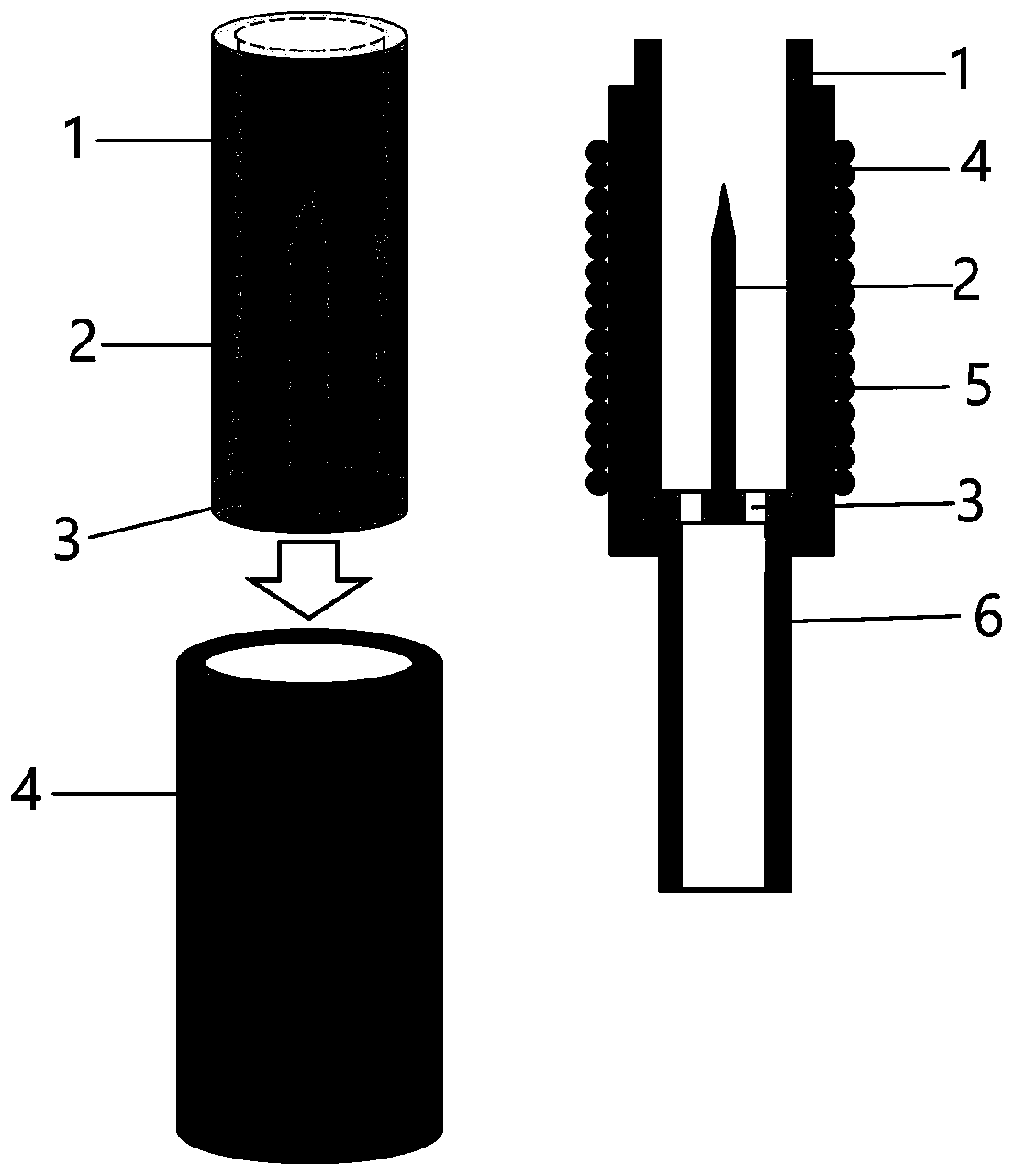

[0051] Embodiment 1: The heating device of the present invention for heating non-burning smoking utensils

[0052] The implementation mode of this embodiment is as follows:

[0053] The heating device includes a fixed cup 1, an electromagnetic induction heating element 2, an air flow channel 3, a heating chamber 4, an induction coil 5 and a device bracket 6; 3. An electromagnetic induction heating element 2 is fixedly installed in the middle of its bottom parallel to its side wall; an induction coil 4 is installed close to the outer wall of the heating chamber 4; the bottom of the heating chamber 4 is connected to the device bracket 6;

[0054] Wherein: the fixed cup 1 is a cylindrical cup with an inner diameter of 4.5mm, and its upper end surface exceeds the upper end surface of the heating cavity 4 . The heating chamber 4 is a hollow cylindrical chamber with an inner diameter of 2.5mm; the fixed cup 1 and the heating chamber 4 are made of ceramic materials sold by Yixing Ji...

Embodiment 2

[0060] Embodiment 2: The heating device of the present invention for heating non-burning smoking utensils

[0061] The implementation mode of this embodiment is as follows:

[0062] The heating device includes a fixed cup 1, an electromagnetic induction heating element 2, an air flow channel 3, a heating chamber 4, an induction coil 5 and a device bracket 6; 3. An electromagnetic induction heating element 2 is fixedly installed in the middle of its bottom parallel to its side wall; an induction coil 4 is installed close to the outer wall of the heating chamber 4; the bottom of the heating chamber 4 is connected to the device bracket 6;

[0063] Wherein: the fixed cup 1 is a cylindrical cup with an inner diameter of 6.0mm, and its upper end surface exceeds the upper end surface of the heating cavity 4 . The heating chamber 4 is a hollow cylindrical chamber with an inner diameter of 3.8 mm; the fixed cup 1 and the heating chamber 4 are made of glass materials sold by Shanghai S...

Embodiment 3

[0069] Embodiment 3: The heating device of the present invention for heating non-burning smoking utensils

[0070] The implementation mode of this embodiment is as follows:

[0071] The heating device includes a fixed cup 1, an electromagnetic induction heating element 2, an air flow channel 3, a heating chamber 4, an induction coil 5 and a device bracket 6; 3. An electromagnetic induction heating element 2 is fixedly installed in the middle of its bottom parallel to its side wall; an induction coil 4 is installed close to the outer wall of the heating chamber 4; the bottom of the heating chamber 4 is connected to the device bracket 6;

[0072] Wherein: the fixed cup 1 is a cylindrical cup with an inner diameter of 8.0mm, and its upper end surface exceeds the upper end surface of the heating cavity 4 . The heating chamber 4 is a hollow cylindrical chamber with an inner diameter of 1.2 mm; the fixed cup 1 and the heating chamber 4 are high-temperature plastic materials sold by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com