Material cleaning equipment and material cleaning method

A technology for cleaning equipment and materials, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc. High performance and efficiency, low cost, simple and convenient wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

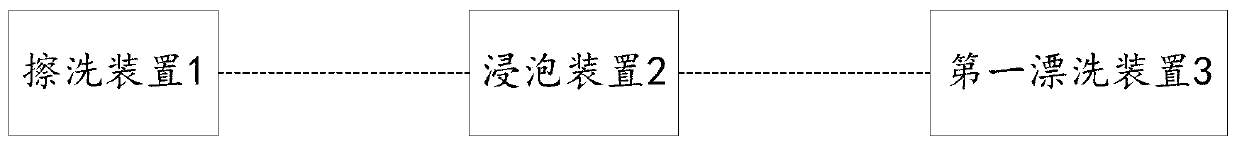

[0048] refer to figure 1 , which shows a structural block diagram of an embodiment of a material cleaning device of the present invention, which may specifically include:

[0049] The scrubbing device 1 is used for scrubbing the materials to be cleaned.

[0050]Wherein, the surface of the material to be cleaned may adhere to metal ions and mud, and the surface of the material to be cleaned may also adhere to other substances that can be scrubbed off. Specifically, the material to be cleaned may be a non-metallic material, such as silicon material.

[0051] The scrubbing device 1 can remove mud and other substances that can be scrubbed off the surface of the material to be cleaned.

[0052] The soaking device 2, the feeding end of the soaking device 2 is adapted to the discharge end of the scrubbing device 1, the soaking device 2 is used to hold the citric acid solution, and the soaking device 2 is also used to soak the scrubbed material in the citric acid solution.

[0053]...

Embodiment 2

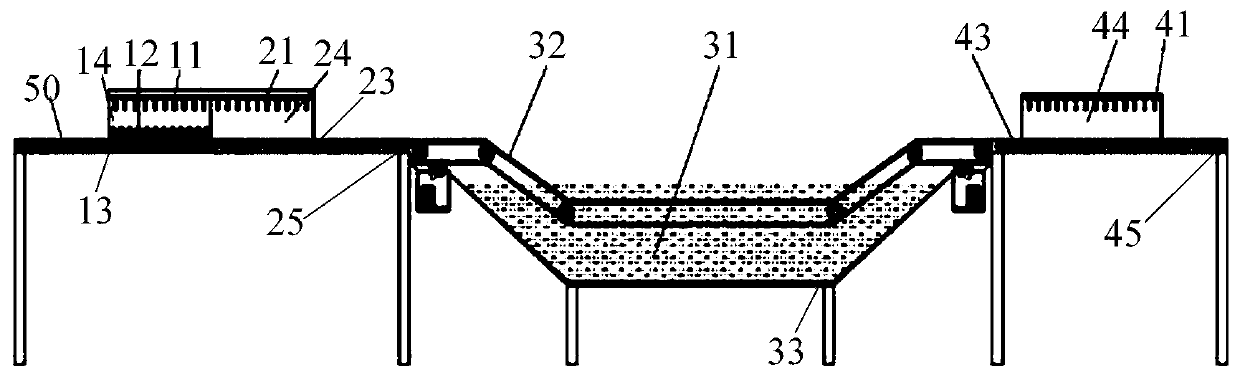

[0064] refer to figure 2 , which shows a structural block diagram of another material cleaning equipment embodiment of the present invention, which may specifically include:

[0065] The scrubbing device 10 is used for scrubbing the materials to be cleaned.

[0066] Wherein, the surface of the material to be cleaned may adhere to metal ions and mud, and the surface of the material to be cleaned may also adhere to other substances that can be scrubbed off. Specifically, the material to be cleaned may be a non-metallic material, such as silicon material.

[0067] Optionally, the scrubbing device 10 may use cleaning liquid to wet the material when scrubbing the material to be cleaned. Wherein, the cleaning liquid may be water, alcohol or the like.

[0068] The second rinsing device 20, the feed end and the discharge end of the second rinsing device 20 are respectively adapted to the discharge end of the scrubbing device 10 and the feed end of the soaking device 30, and the se...

Embodiment 3

[0099] refer to Figure 4 , which shows a flow chart of the steps of an embodiment of a material cleaning method of the present invention, which may specifically include the following steps:

[0100] S1, scrubbing the material to be cleaned.

[0101] Wherein, the surface of the material to be cleaned may adhere to metal ions and mud, and the surface of the material to be cleaned may also adhere to other substances that can be scrubbed off. Specifically, the material to be cleaned may be a non-metallic material, such as silicon material.

[0102] Step S1 can remove mud and other substances that can be scrubbed off the surface of the material to be cleaned.

[0103] S2, soaking the scrubbed material in a citric acid solution.

[0104] Step S2 can remove the metal ions on the surface of the scrubbed material.

[0105] Optionally, the concentration of the citric acid solution can be 5% to 50%, the temperature of the citric acid solution can be greater than or equal to 10 degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com