Normal-position turning device for railway vehicle testable track wheel

A technology for railway vehicles and rail wheels, which is applied to turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of large tool holder size, complicated installation and use, and difficulty in popularization and use, and achieve simple turning repair and light weight , The effect of high power output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

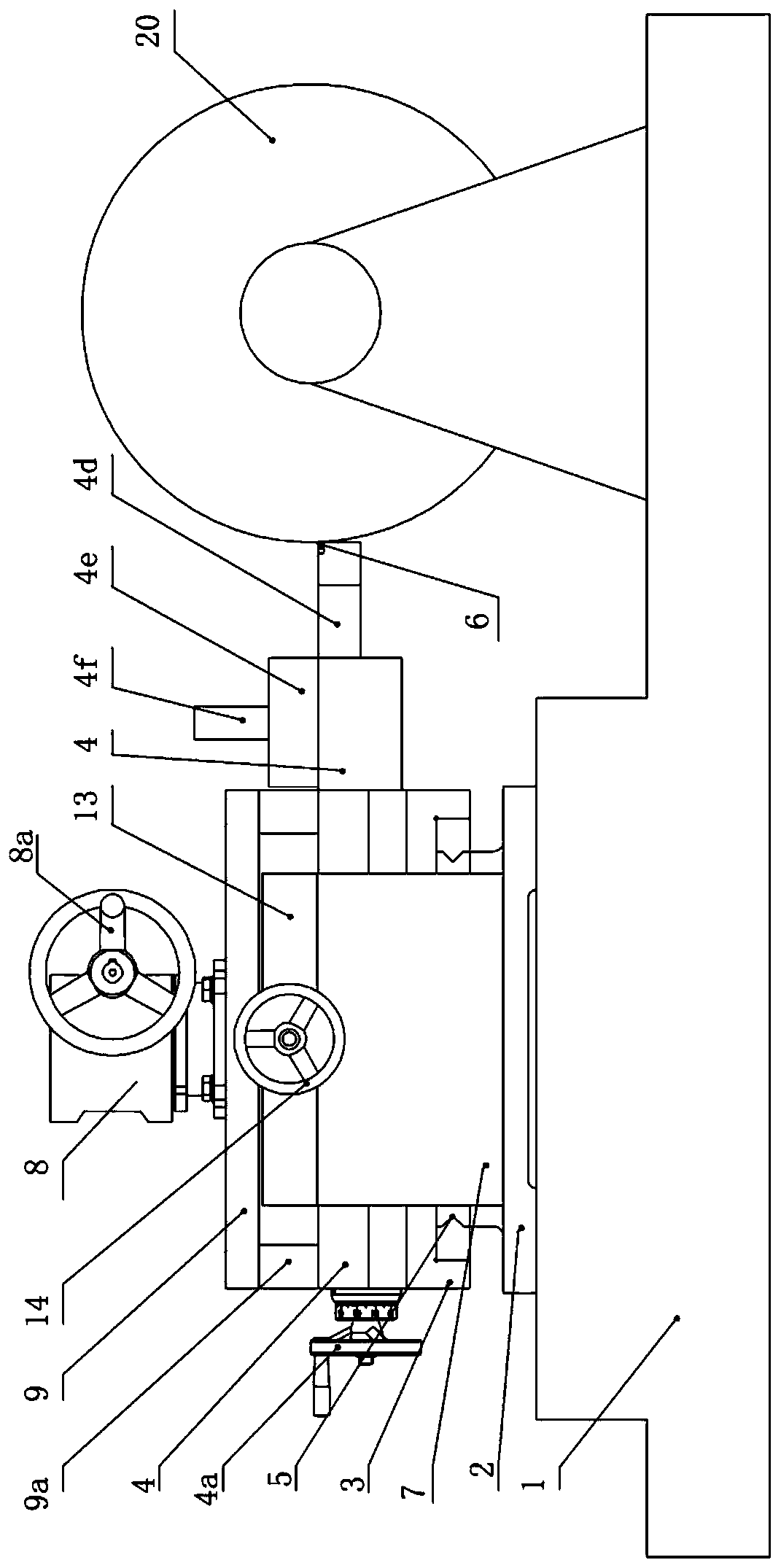

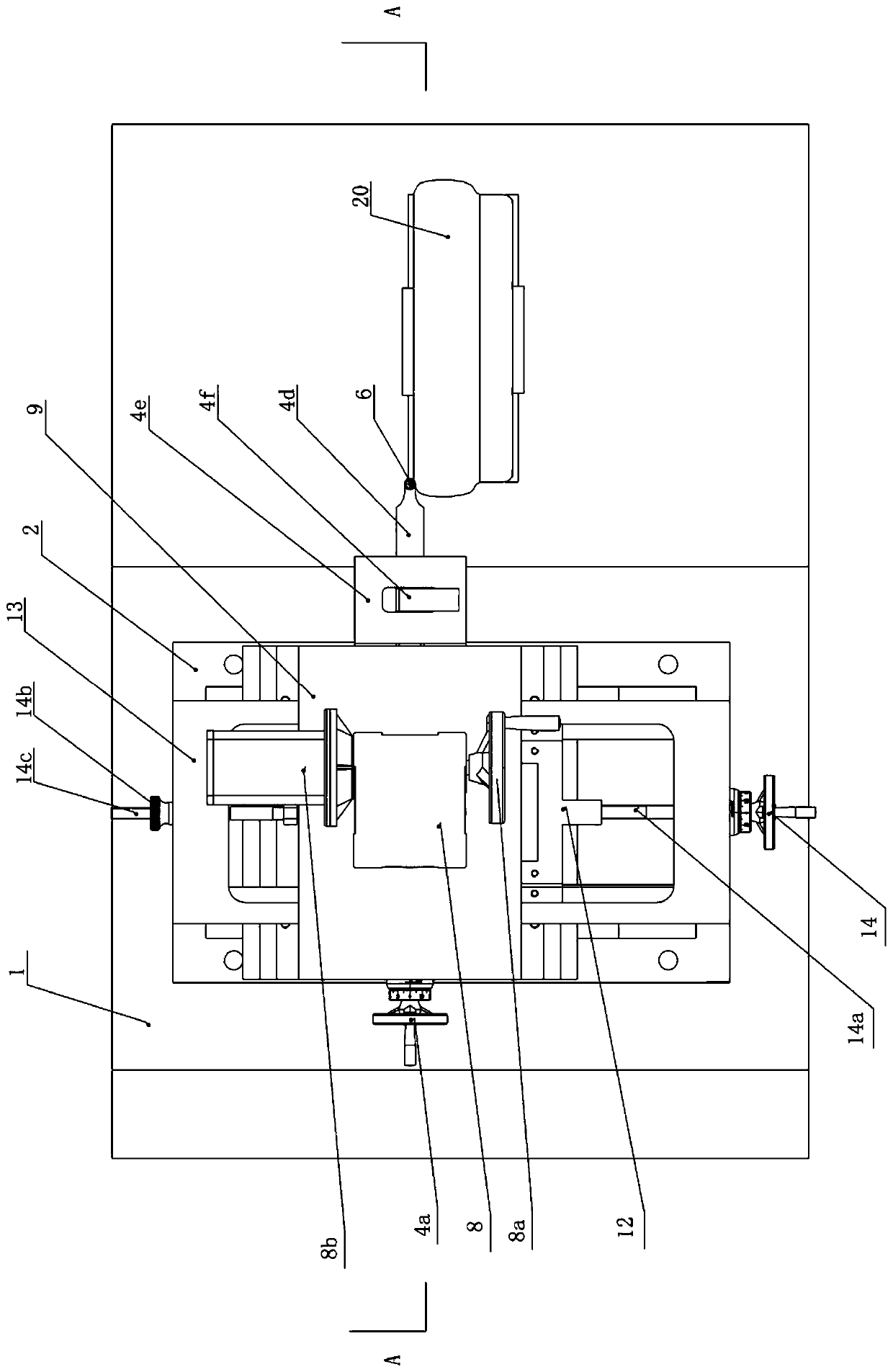

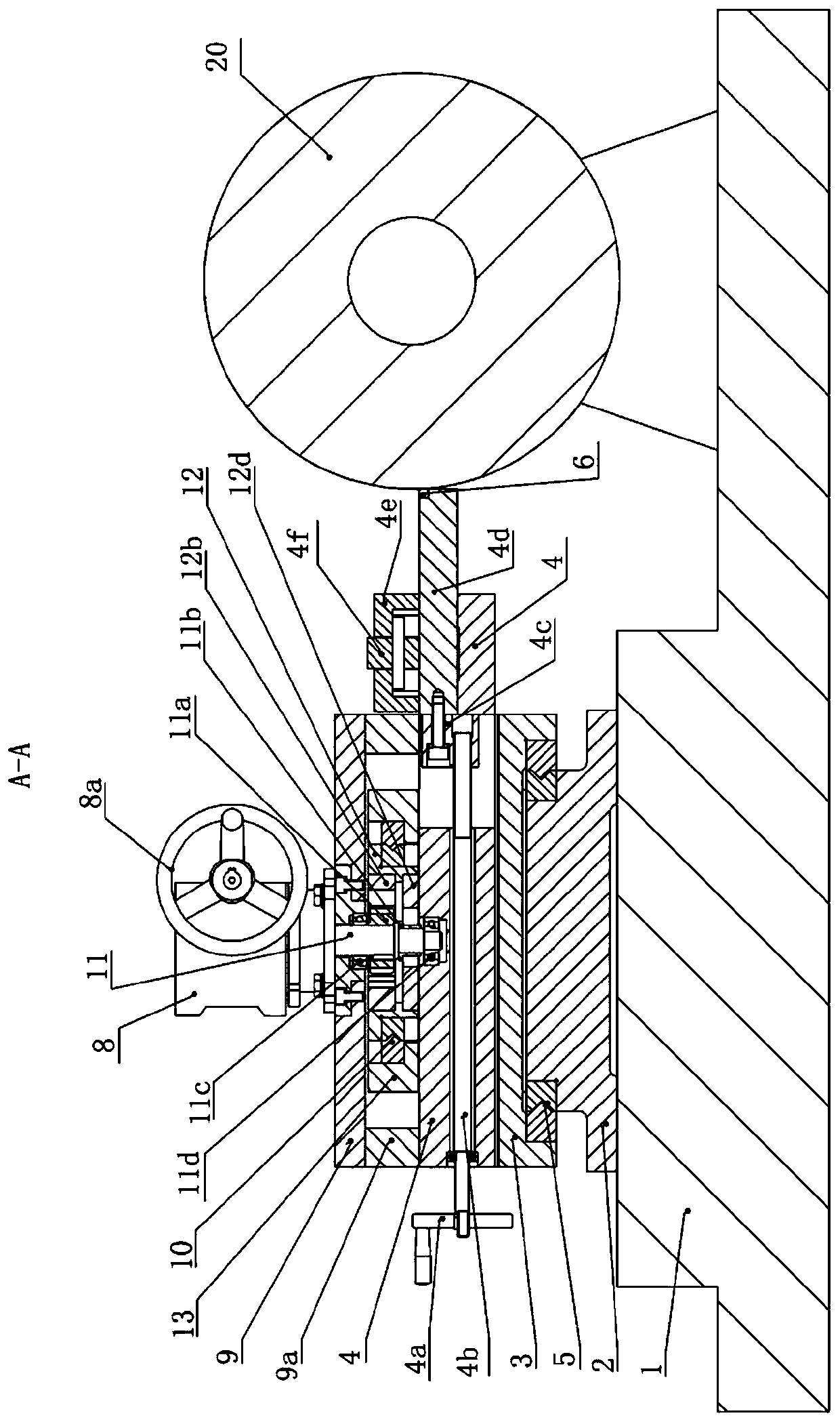

[0040] Figure 1-3 Shown, a kind of specific embodiment of the present invention is, a kind of in-situ turning device of rail wheel of railway vehicle test bench, comprises: the rail wheel base 1 of rail vehicle rolling test bench, the right part of rail wheel base 1 installation Rail wheel 20 is characterized in that:

[0041]The upper left part of the track wheel base 1 is equipped with a two-dimensional mobile platform, the upper part of the two-dimensional mobile platform is a horizontal mobile platform 4, the middle part is a vertical mobile platform 3, and the bottom part is a base plate 2;

[0042] In the transverse through hole of described transverse mobile platform 4, be provided with feed screw mandrel 4b, cutter bar connecting block 4c and turning tool bar 4d successively from left to right; The knife hand wheel 4a is connected, the screw thread at the right end of the feed screw 4b matches the threaded hole of the knife bar connecting block 4c, the right end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com