A kind of automatic composite technology process method of cup-shaped mask

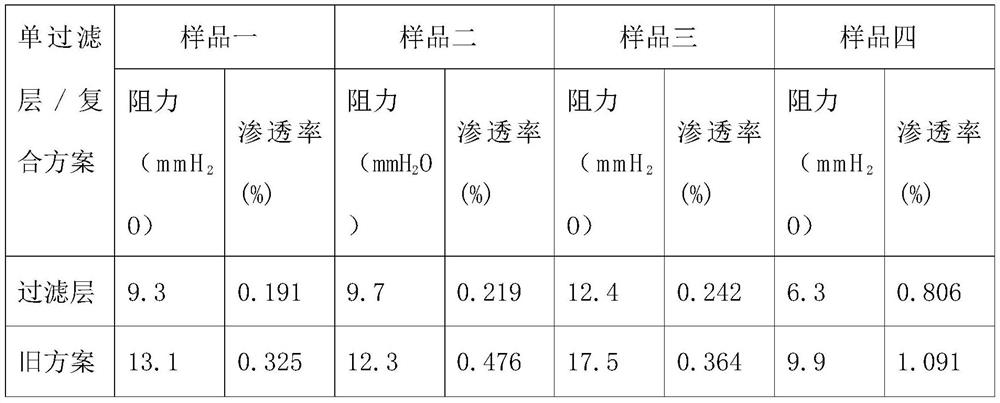

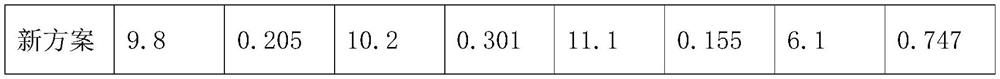

A process method and composite technology technology, which is applied in the field of automatic composite technology for cup-shaped masks, can solve the problems of unstable filtration efficiency, low efficiency, and electrostatic decay cycle damage, and achieve the goal of not reducing filtration efficiency, high efficiency, and low resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present invention provides a technical solution: a cup-shaped mask automatic composite technology process, comprising the following steps:

[0028] S1, mold preparation and material preparation, prepare the mold required for the composite process, clean the mold, adjust the mold parameters to appropriate values, and prepare the materials required for the composite process, including; The inner layer of the mask and the outer layer of the mask;

[0029] S2, material loading, fix the roll material of the middle filter layer on one side of the mold, and the roll material can be rotated in the mold; pull the head of the middle filter layer to the other side of the lower mold, and reserve a certain length of material at the head of the mold, The required length and size range is 12-15cm;

[0030] S3, the filter layer is finalized, and the upper mold cores are dropped one by one. There are two ways to choose the falling direction. Method 1: the falling direction is from ...

Embodiment 2

[0041] The present invention provides a technical solution: a cup-shaped mask automatic composite technology process, comprising the following steps:

[0042] S1, mold preparation and material preparation, prepare the mold required for the composite process, clean the mold, adjust the mold parameters to appropriate values, and prepare the materials required for the composite process, including; The inner layer of the mask and the outer layer of the mask;

[0043]S2, material loading, fix the roll material of the middle filter layer on one side of the mold, and the roll material can be rotated in the mold; pull the head of the middle filter layer to the other side of the lower mold, and reserve a certain length of material at the head of the mold, The required length and size range is 12-15cm;

[0044] S3, the filter layer is finalized, and the upper mold cores are dropped one by one. There are two ways to choose the falling direction. Method 1: the falling direction is from o...

Embodiment 3

[0055] The present invention provides a technical solution: a cup-shaped mask automatic composite technology process, comprising the following steps:

[0056] S1, mold preparation and material preparation, prepare the mold required for the composite process, clean the mold, adjust the mold parameters to appropriate values, and prepare the materials required for the composite process, including; The inner layer of the mask and the outer layer of the mask;

[0057] S2, material loading, fix the roll material of the middle filter layer on one side of the mold, and the roll material can be rotated in the mold; pull the head of the middle filter layer to the other side of the lower mold, and reserve a certain length of material at the head of the mold, The length size range is required to be 15mm;

[0058] S3, the filter layer is finalized, and the upper mold cores are dropped one by one. There are two ways to choose the falling direction. Method 1: the falling direction is from o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com