Multi-station crystallization cylinder barrel of dry ice machine

A multi-station, dry ice technology, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve problems such as low efficiency, and achieve the effect of improving efficiency and avoiding life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

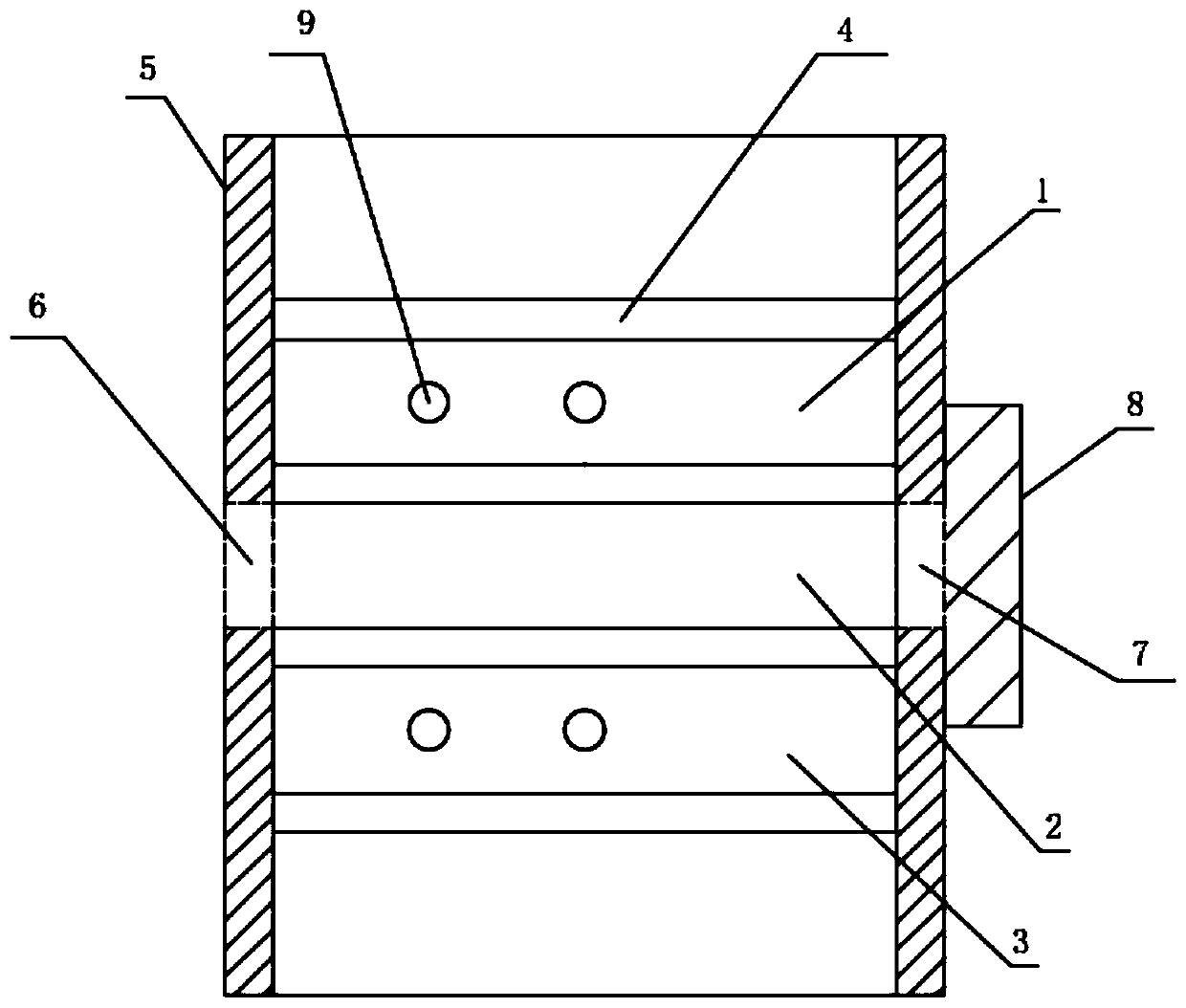

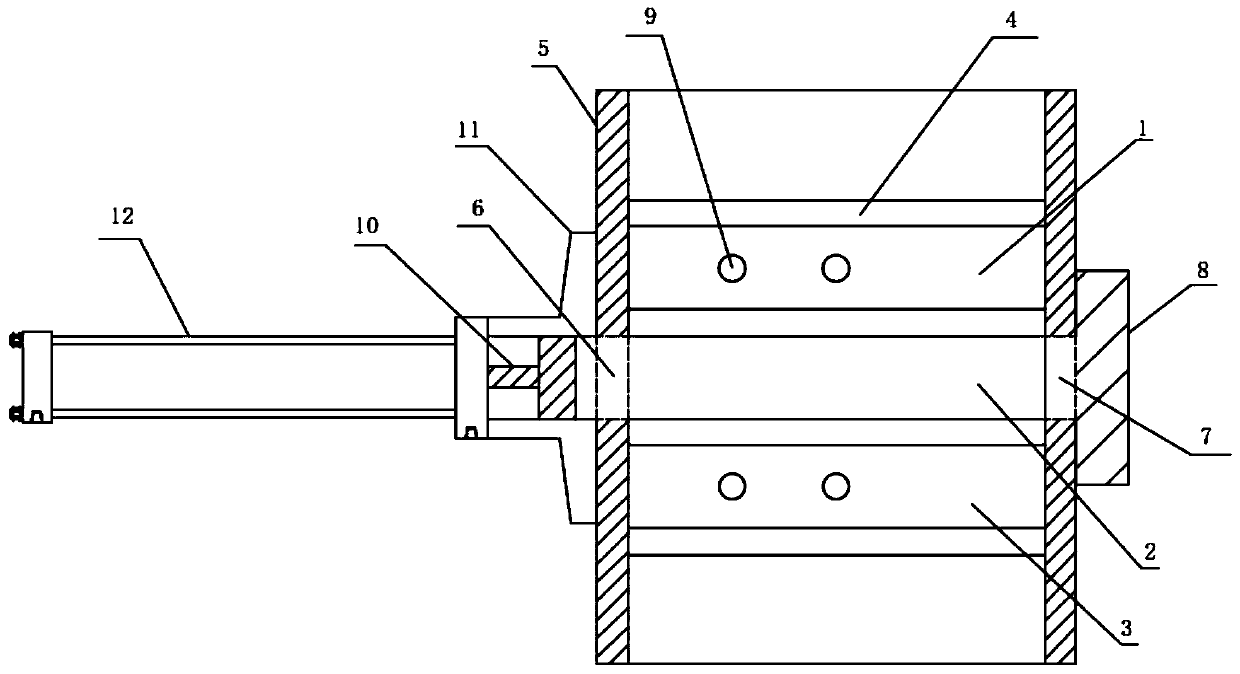

[0028] like figure 1 As shown, a dry ice machine multi-station crystallization cylinder of the present invention includes two parallel side plates 5 and four parallel partitions 4 vertically connected between the two side plates 5; two adjacent partitions The spacing of the plates 4 is the same;

[0029] The bottom of the partition 4 is horizontally connected with a carriage perpendicular to the four partitions 4, and the top of the partition 4 is horizontally provided with a top plate; the top board, the carriage and every two adjacent partitions 4 form a cylinder chamber; the cylinder chamber It includes the first cylinder chamber 1 and the third cylinder chamber 3 on both sides, and the second cylinder chamber 2 in the middle;

[0030] The middle part of two side plates 5 is respectively provided with piston inlet 6 and dry ice outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com