Method for preparing high-purity alpha-PbO from beta-PbO

A technology of steel and vacuum balls, applied in the direction of lead monoxide and lead oxide, which can solve the problems of difficult to obtain α-PbO, and achieve the effect of high production cost, simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Put β-PbO powder (particle size 100-200nm) in a vacuum ball mill jar, then seal it tightly, pass argon gas into the vacuum ball mill jar for three times, and then evacuate the vacuum ball mill jar to 100Pa.

[0034] (2) Put the vacuum ball mill tank of the step (1) on a (QM-3SP2) planetary ball mill for ball milling to finally obtain α-PbO; the vacuum ball milling time is 14h; the vacuum ball milling speed is 425rmp ; The vacuum pressure in the vacuum ball milling tank is 100Pa; the mass ratio of the quality of the steel ball milling balls in the vacuum ball milling tank to the β-PbO loaded in the vacuum ball milling tank is 15:1. After testing, the purity of α-PbO was 99.2%.

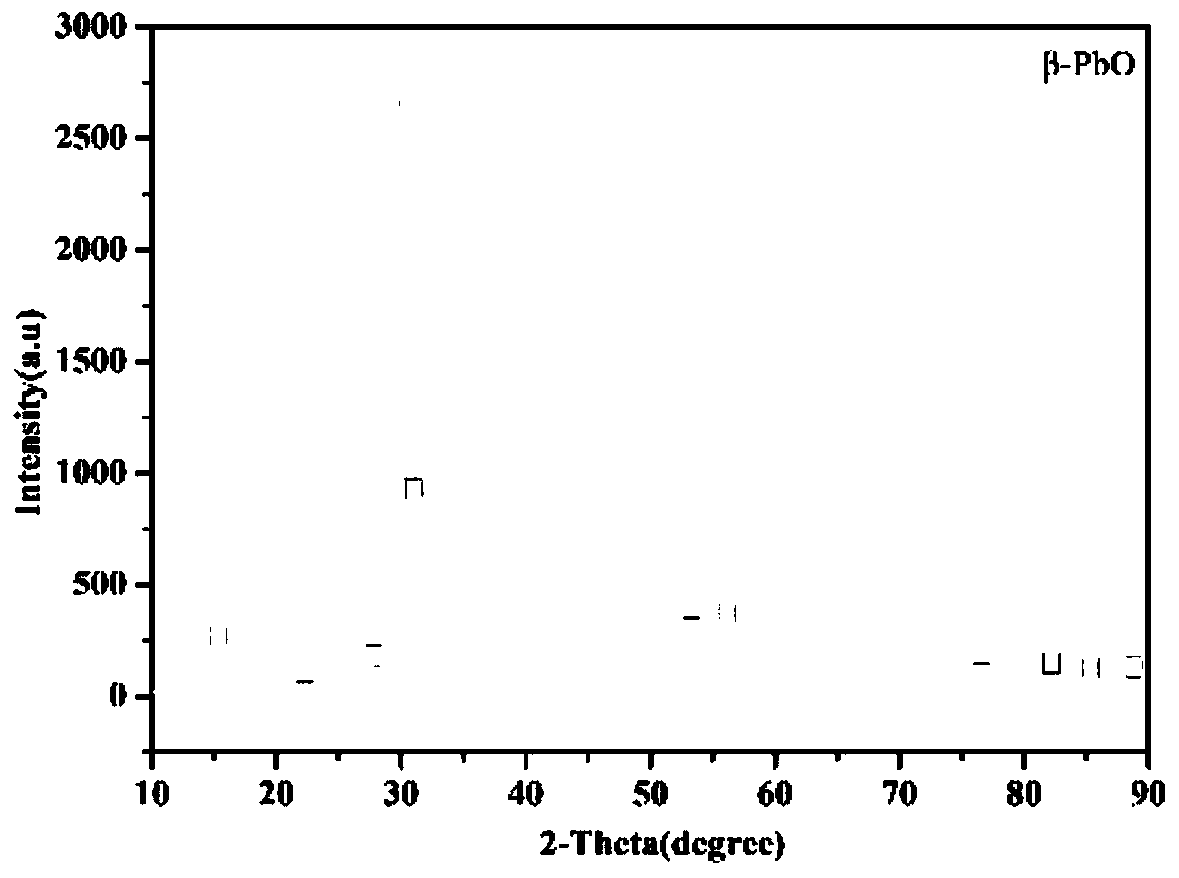

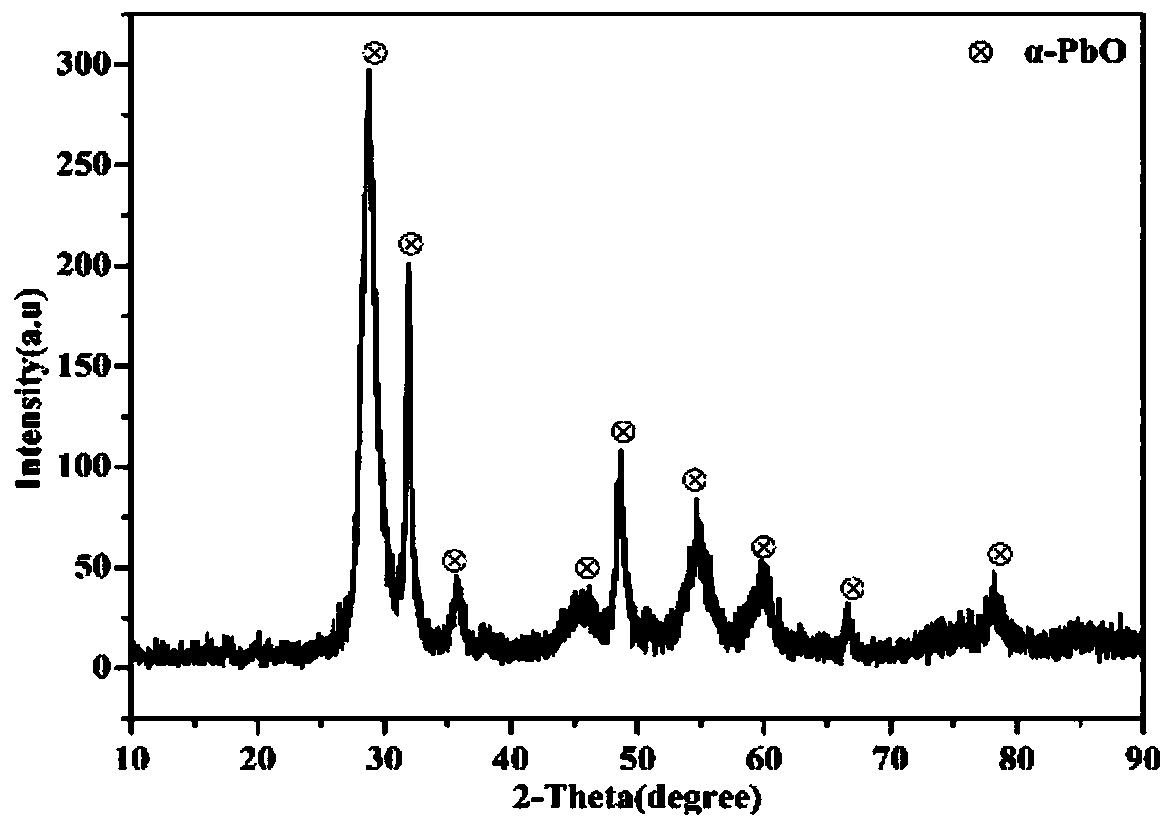

[0035] figure 1 It is the XRD figure of the raw material β-PbO adopted in the present invention; figure 2 It is the XRD figure of the product α-PbO of vacuum ball milling of the present invention, according to Figure 1~2 It can be seen that the present invention has indeed prepared α-PbO...

Embodiment 2

[0037] (1) Put β-PbO powder (particle size 100-200nm) in a vacuum ball mill jar, then seal it tightly, pass argon gas into the vacuum ball mill jar for three times, and then evacuate the vacuum ball mill jar to 1Pa.

[0038] (2) Put the vacuum ball mill tank of the step (1) on a (QM-3SP2) planetary ball mill for ball milling to finally obtain α-PbO; the vacuum ball milling time is 20h; the vacuum ball milling speed is 500rmp The vacuum pressure in the vacuum ball milling tank is 1Pa; the mass ratio of the quality of the steel ball milling balls in the vacuum ball milling tank to the loaded β-PbO is 20:1. After testing, the purity of α-PbO was 99.5%.

Embodiment 3

[0040] (1) Put β-PbO powder (particle size 100-200nm) in a vacuum ball mill jar, then seal it tightly, pass argon gas into the vacuum ball mill jar for three times, and then evacuate the vacuum ball mill jar to 50Pa.

[0041] (2) Put the vacuum ball milling tank of the step (1) on a (QM-3SP2) planetary ball mill for ball milling to finally obtain α-PbO; the vacuum ball milling time is 17h; the vacuum ball milling speed is 460rmp The vacuum pressure in the vacuum ball milling tank is 50Pa; the mass ratio of the quality of the steel ball milling balls in the vacuum ball milling tank to the β-PbO loaded in the vacuum ball milling tank is 17:1. After testing, the purity of α-PbO was 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com