Electromagnetically driven braided fabric pulling device

A pulling device and knitted fabric technology, applied in weft knitting, warp knitting, knitting and other directions, can solve the problems of increased scrap rate, loss of rubber layer, easy deformation of knitted fabric, etc. And the effect of easy maintenance, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

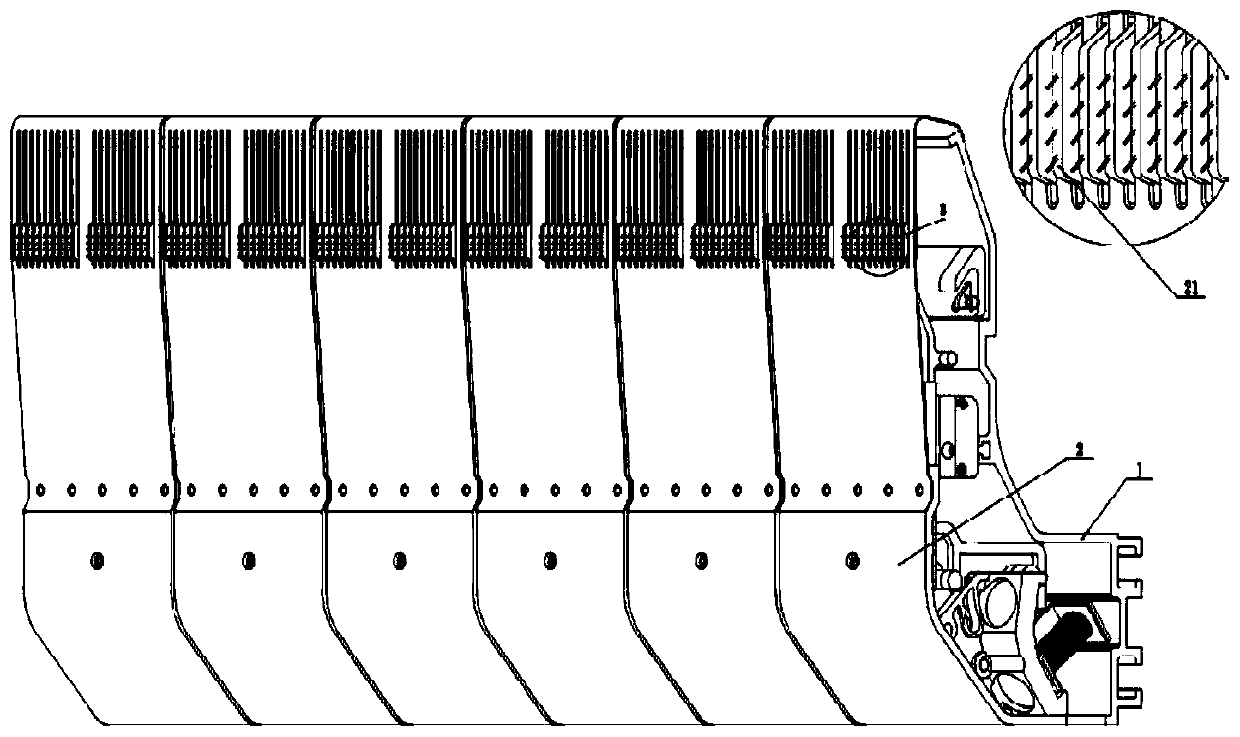

[0024] Such as figure 1 , 2 As shown, the present invention provides an electromagnetically driven braid pulling device, including a housing, a driving module, and a lifting module, wherein the driving module and the lifting module are all connected to the housing 1, and the driving module is connected to the lifting module through a push-pull rod. Connected, the drive module changes the current through the electromagnet to produce a position change between the permanent magnet groups, driving the push-pull rod 11 to move up and down; thus driving the slide rail in the lifting module to move up and down, the upper end of the slide rail is connected to the needle claw 21, and the needle claw moves up and down Complete the pull.

[0025] Preferably, as Figure 7 As shown, several pulling devices are arranged in pairs under the needle bed with claws facing each other, A1 pulls the fabric 103 knitted by the front needle bed 101, and A2 pulls the fabric 104 knitted by the rear ne...

Embodiment 2

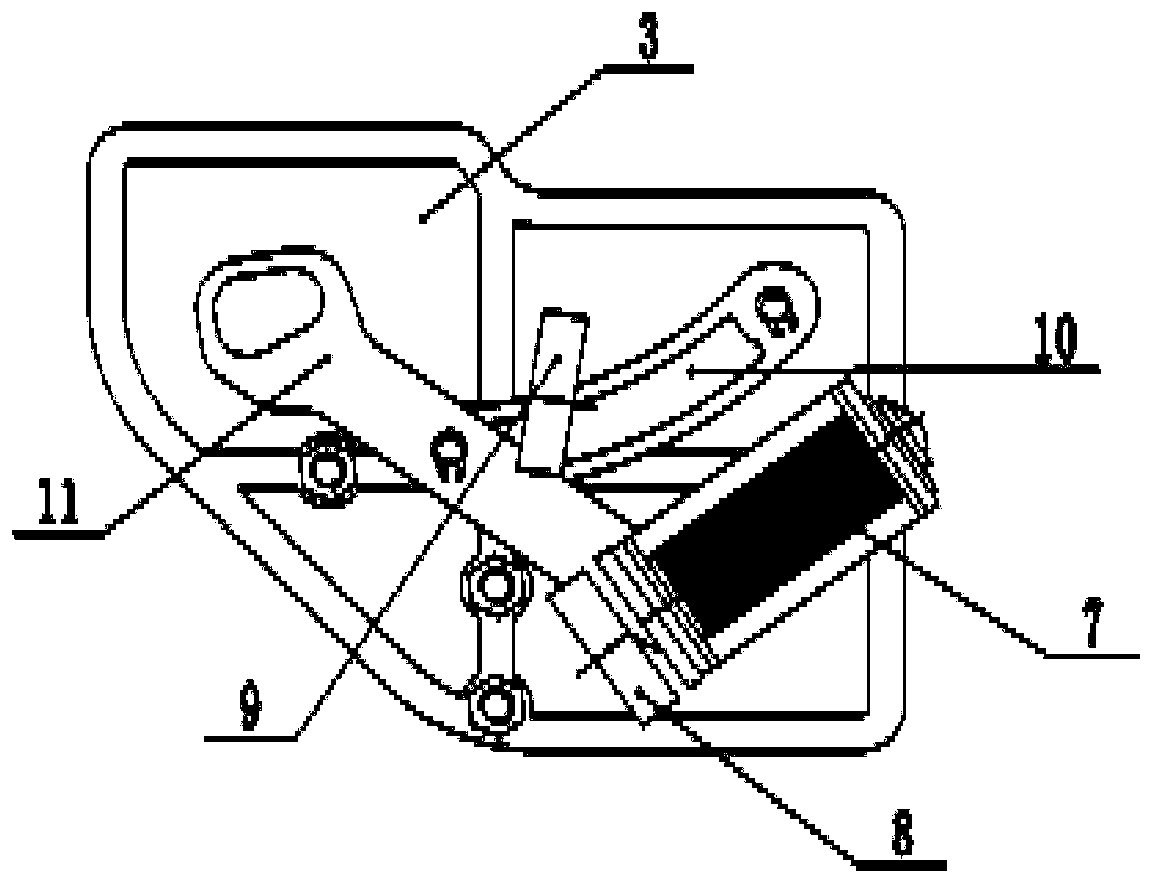

[0027] driver module

[0028] image 3 , Figure 4 It is a structural diagram of the drive module in the embodiment of the present invention. As shown in the figure, the drive module includes a support plate 3, an upper link 10, a lower link 12, a push-pull rod 11, an electromagnet 7 and a permanent magnet group. The support plate is fixed in the housing, the tail ends of the upper link and the lower link are respectively connected to the support plate through the rotation axis B14 and the rotation axis A13, and the push-pull rod is respectively connected with the upper link and the lower link by the rotation axis C15 and the rotation axis D16. The head end of the bar is connected, the electromagnet is fixed on the lower connecting rod, and the permanent magnet group is arranged at the electromagnet rear, is made up of upper and lower permanent magnets A8 and permanent magnets B9 whose magnetism is opposite, and is fixed on the magnet seat 4.

[0029] When the electromagnet ...

Embodiment 3

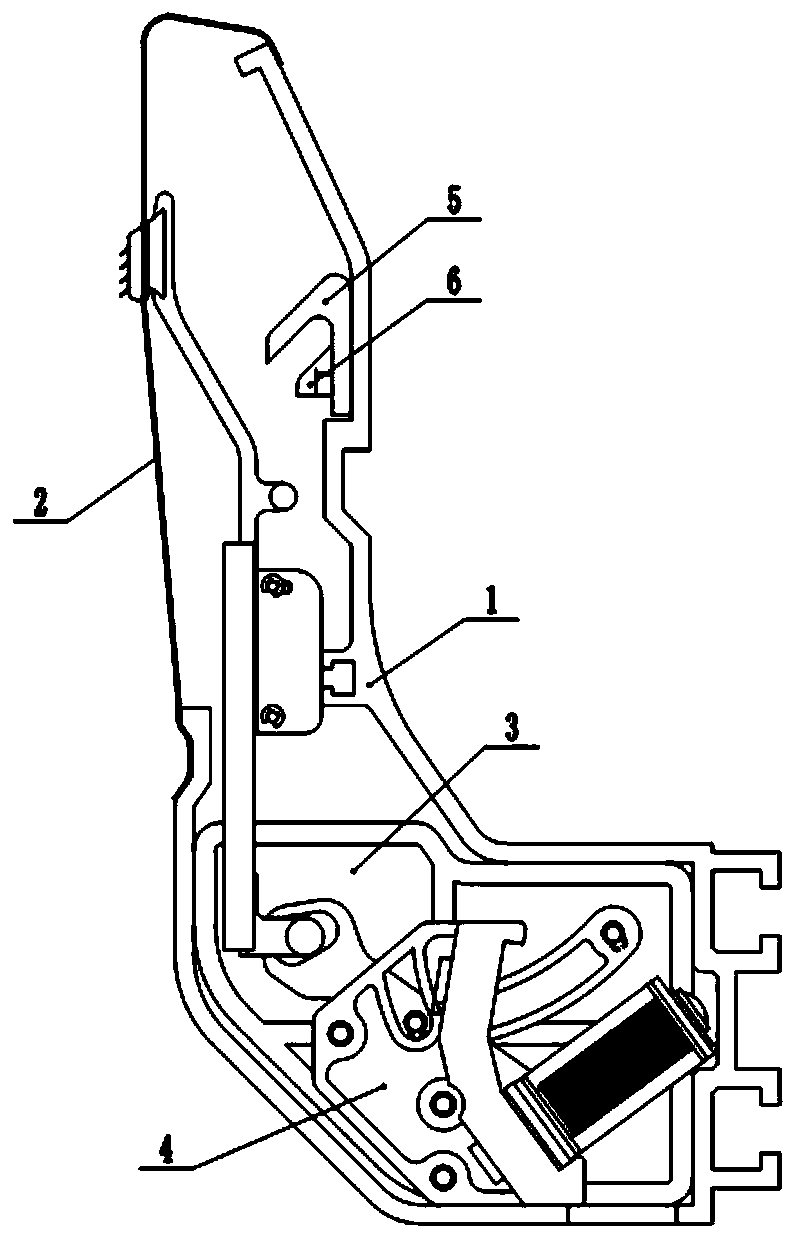

[0033] lift module

[0034] Such as Figure 5 , Figure 6 As shown, the pulling mechanism includes the needle claw 21, the needle claw seat 20, the slide rail 17, and the bearing seat 23 connected sequentially from top to bottom. A bearing B22 is provided in the middle of the needle claw seat, and a chute is provided on the slide rail. A slide block 18 is connected in the chute, and the swing block 27 is fixedly connected to the slide block. The swing block is connected with the swing seat 19 through the rotating shaft E25 and the limit shaft F26, and the bearing seat is provided with a bearing A24. The bearing A is connected to the drive. In the control slot on the push-pull rod of the module.

[0035] The pulling device is also provided with a baffle plate 2, which is fixed on the outer side of the needle claw seat on the housing, and a plurality of grooves for the needle claws to pass are arranged on the baffle plate.

[0036] When the slide rail 17 is under force, it ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com