Anti-cover drill rod and anti-cover drill

A drill pipe and drill bit technology, applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of low drilling speed, limited drilling depth and progress of drilling rigs, prone to cover drilling accidents, etc., and achieve the guarantee of drilling speed. , The effect of preventing cover drilling accidents and reducing slag discharge resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

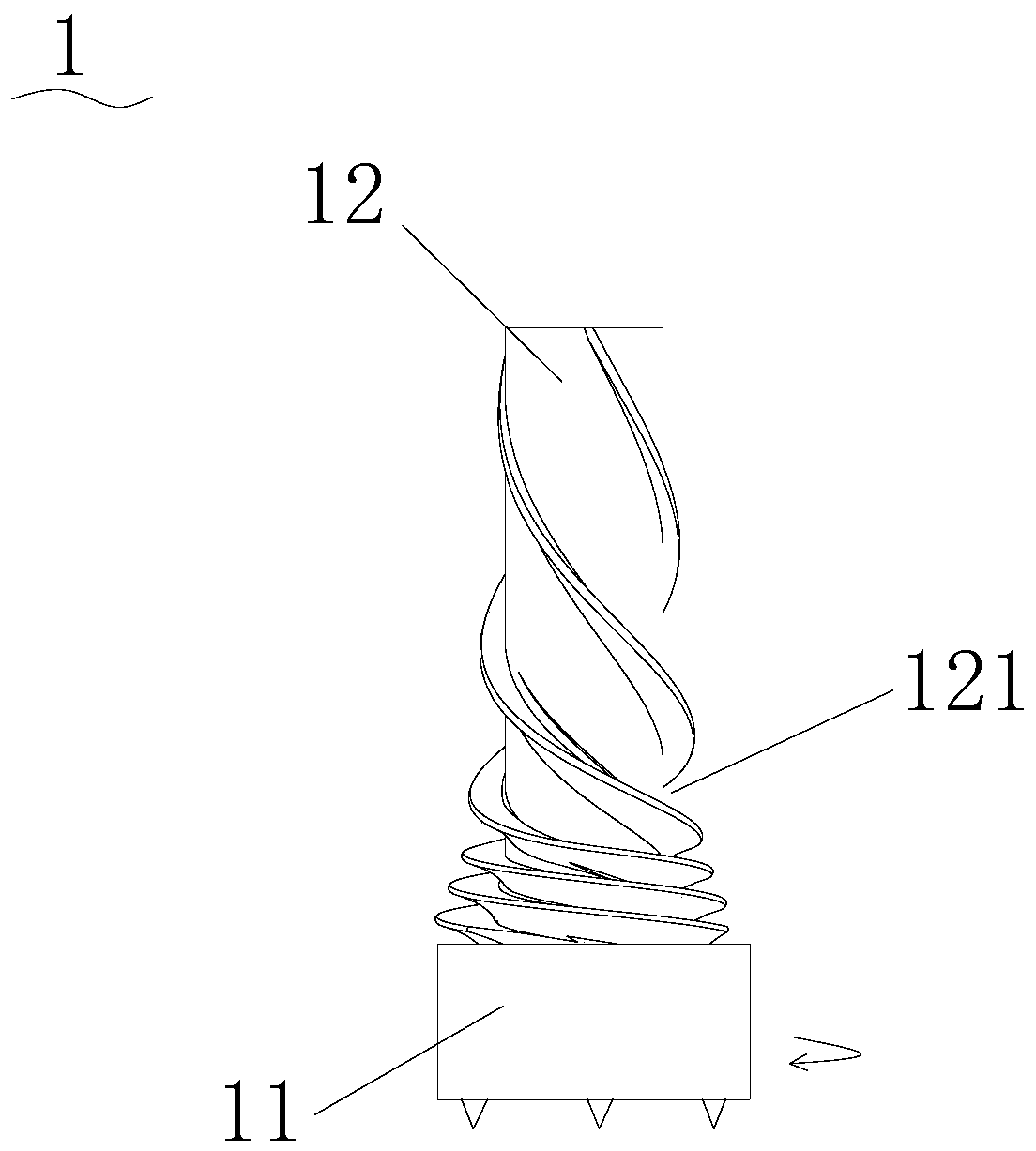

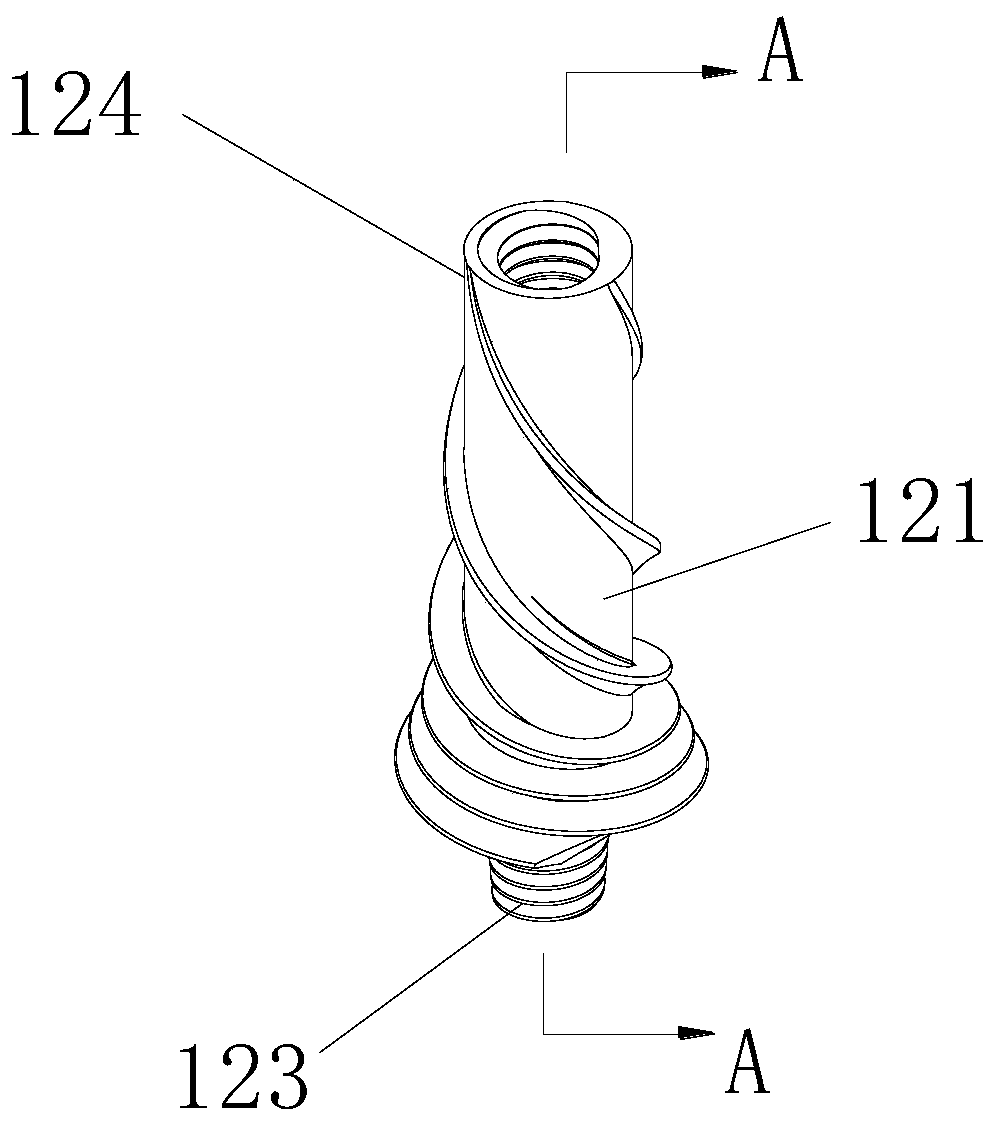

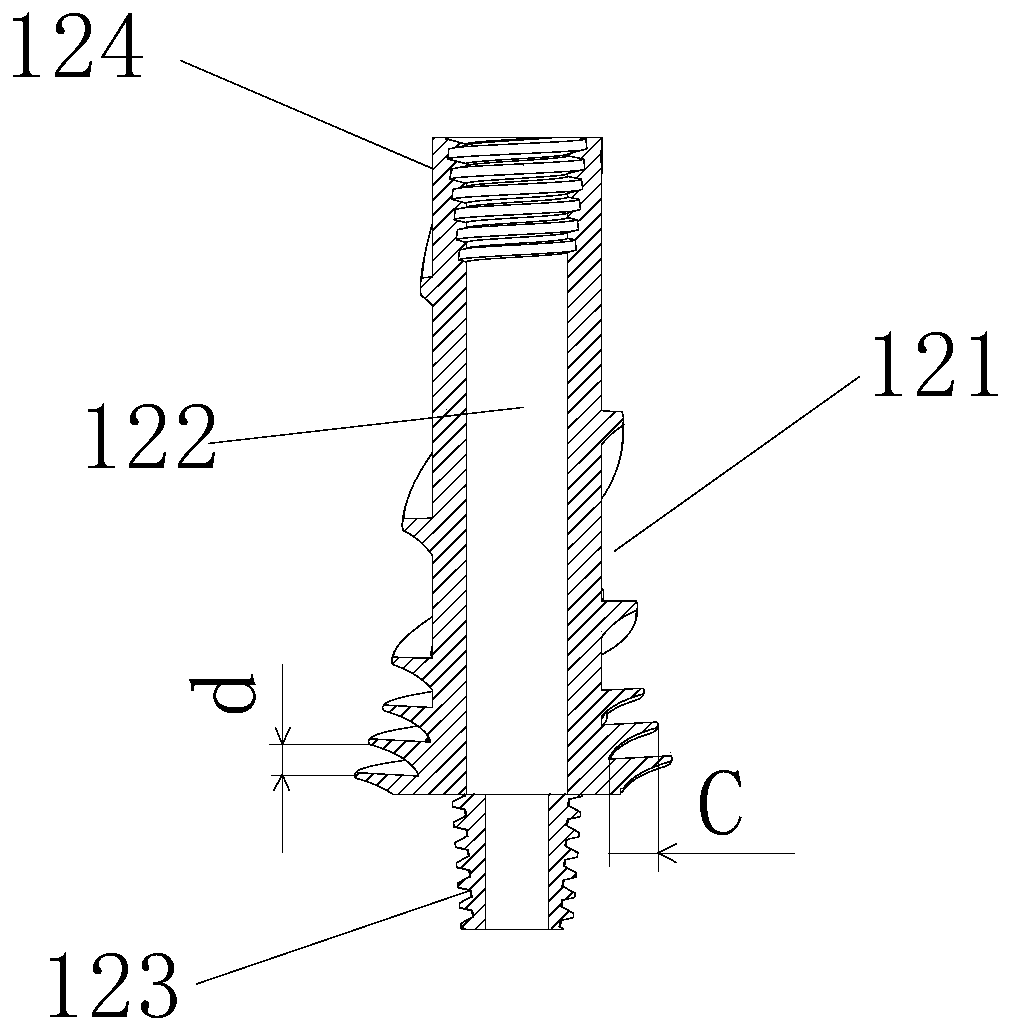

[0023] Such as Figure 1 to Figure 3 As shown, the anti-cover drill 1 of the present invention includes an anti-cover drill rod 12 and a drill bit 11, and the anti-cover drill rod tail end 124 is a drill rod connection end connected with other drill rods, and the anti-cover drill rod head end 123 is connected to the drill rod. The tail ends of the drill bits 11 are connected, that is, the head end 123 of the anti-cover drill pipe is the drill bit connection end, and the anti-cover drill pipe 12 is provided with a through hole 122 for leading the slag discharge medium. In order to prevent drilling, the outer surface of the anti-covering drill rod 12 is provided with a spiral groove 121 whose screw-in direction is opposite to the drilling rotation direction of the drill bit 11 .

[0024] Wherein, the method of judging the screwing direction of the spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com