Coal mine dust control method based on dust concentration

A dust concentration, coal mine technology, applied in the field of coal mine dust control based on dust concentration, can solve the problems of rising dust concentration, unfavorable personal safety of workers, long time, etc., and achieve the effect of improving reliability, ensuring personal safety and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A coal mine dust control method based on dust concentration. Coal mine spray devices are equipped with upper and lower limits of dust concentration. When the dust concentration is detected to be greater than the upper limit, the nozzle is turned on. When the limit value is reached, the nozzle is closed, and the lower limit value of the dust concentration is controlled by the main control unit, so that the lower limit value of the dust concentration is inversely proportional to the time of continuous spraying.

[0024] In this embodiment, the upper limit value of the dust concentration is set to B, and the nozzle control conditions are as follows:

[0025] a. Turn on the nozzle, and when the collected dust concentration is greater than the upper limit value B of the dust concentration, turn on the nozzle.

[0026] b. Close the nozzle, set the lower limit value of the dust concentration to B(1-H), H is the hysteresis ratio of the dust concentration; H=(10+t 开 / 20) / 100,t ...

Embodiment 2

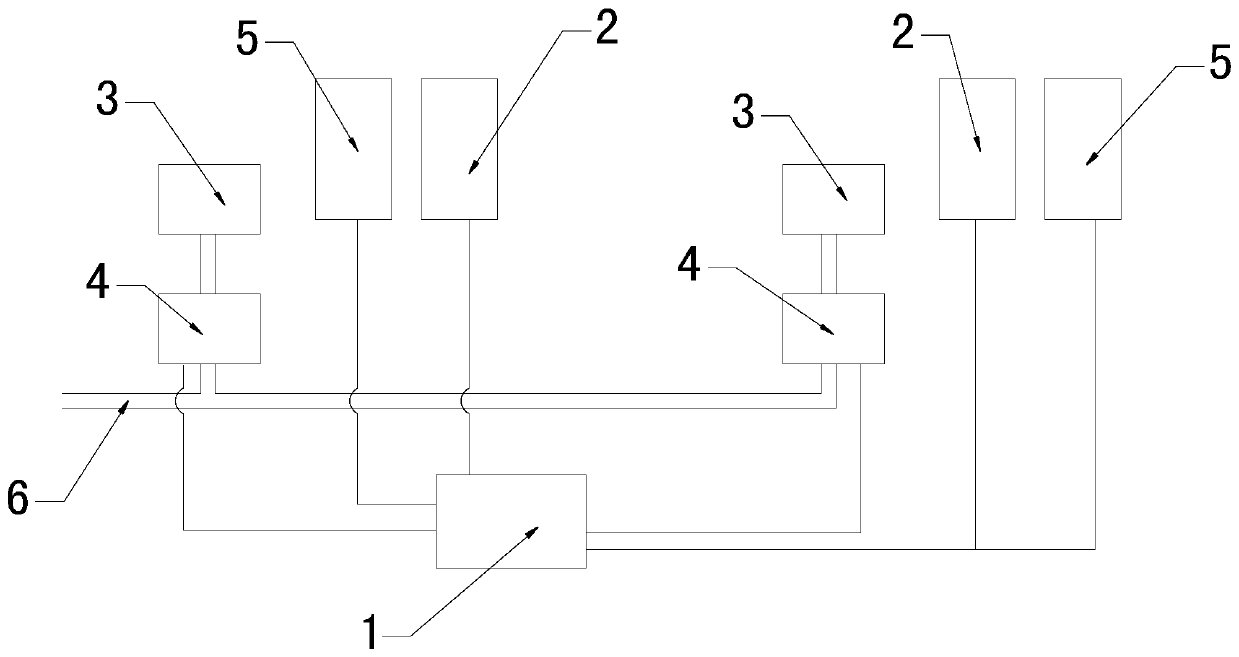

[0034] like figure 1 As shown, in coal mines in the medium range, two sets of devices are needed to meet the requirements of dust reduction. The main control unit 1 is connected with two dust concentration sensors 2, two nozzles 3, two control valves 4 and two Pyroelectric sensor 5, that is, two sets of devices are used for spray dust reduction treatment, and each set of devices adopts the method in Embodiment 1 to flexibly change the hysteresis ratio, and then change the time of spray dust reduction; set two pyroelectric sensors The distance between the sensors 5 is L. When a worker passes by, the pyroelectric sensor 5 receives the heat signal of the worker, and transmits the signal to the main control unit 1, and the main control unit 1 closes the pyroelectric sensor 5 that has collected the heat signal. position of the control valve 4, the closing time of the control valve 4 is (10L / 4)s, and then the control valve 4 returns to its original state, so that workers can pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com