Ignition device for discrete particles of flowing metallic fuel

A metal fuel and ignition device technology, applied in the directions of combustion ignition, incandescent ignition, combustion method, etc., can solve the problems of inconvenient combustion diagnosis, poor structural stability and uniformity of the combustion flame of metal fuel, etc. The effect of discretization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

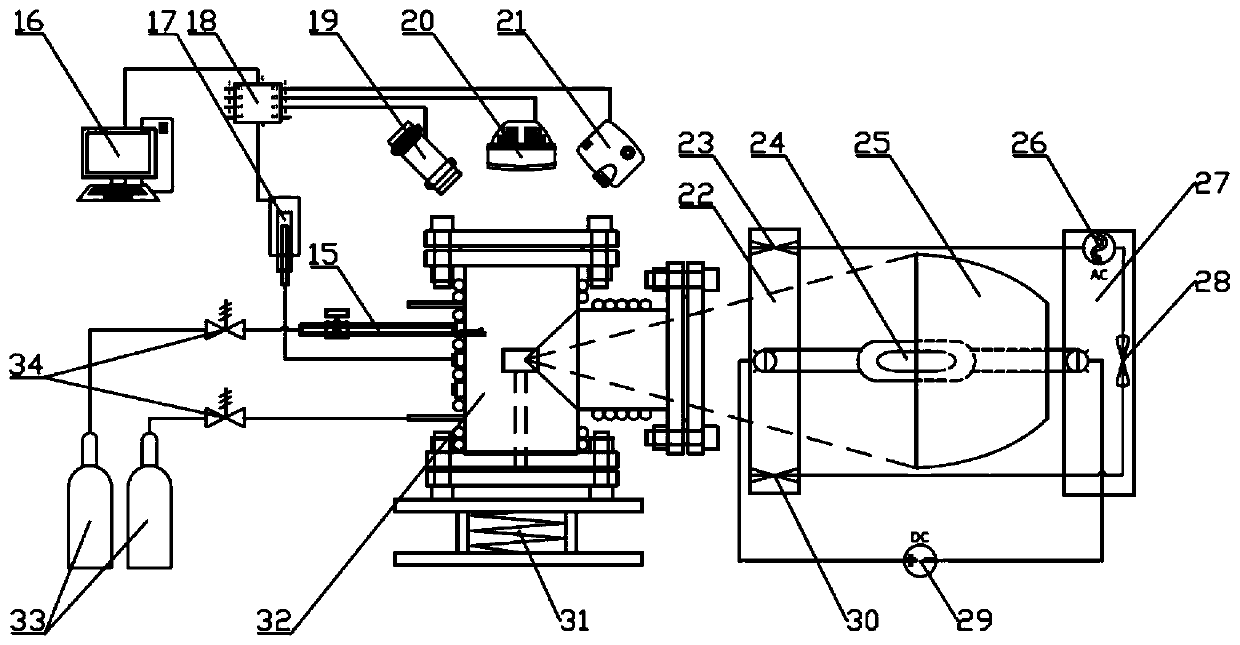

[0023] see Figure 1 to Figure 3 , the ignition device for discrete particles of flowing metal fuel according to an embodiment of the present invention, the device can realize the ignition of discrete particles of flowing metal fuel in a pressure environment, and consists of a jet burner module, a xenon lamp ignition module, and a combustion diagnosis modules and control modules.

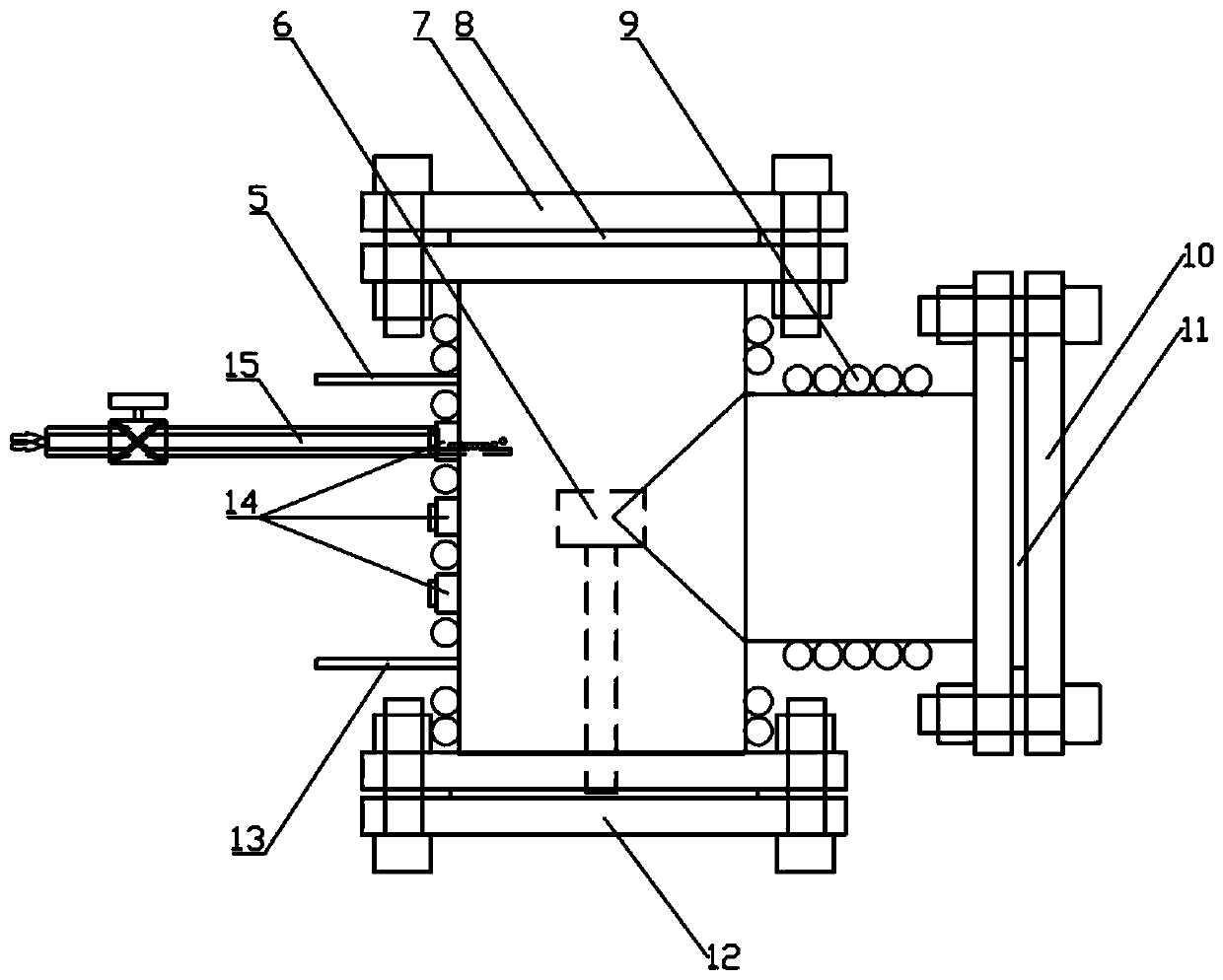

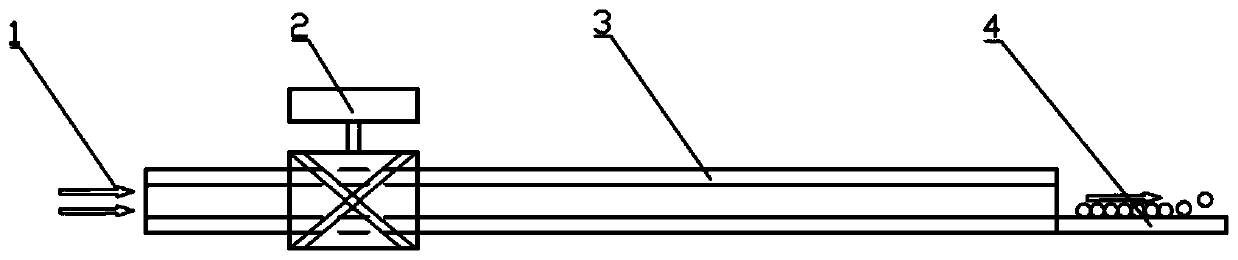

[0024] The jet burner module includes a pressure burner 32, a sample injector 15, and a lifting table 31. The main body of the pressure burner 32 is a horizontal T-shaped stainless steel tee pipe, and the three ports of the tee pipe are respectively connected by a flange I7, a flange Plate Ⅱ10 and flange Ⅲ12 are sealed, and the top port and flange Ⅰ7 are equipped with pressure-resistant quartz glass Ⅰ8 window, and the side port and flange Ⅱ10 are equipped with pressure-resistant quartz glass Ⅱ11 window; the side of the pressure burner has no port There are three measuring holes 14 vertically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com