Furnace-free front storage bin feeding device for biomass power plant

The technology of a feeding device and a screw feeding device is applied in the direction of fuel supply, burning fuel in a molten state, and combustion methods, etc., which can solve the problems of long-term stable operation of the unit, entanglement of conveying fuel, uneven feeding, etc., and achieve a simple and convenient device , Avoid bridging and save floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

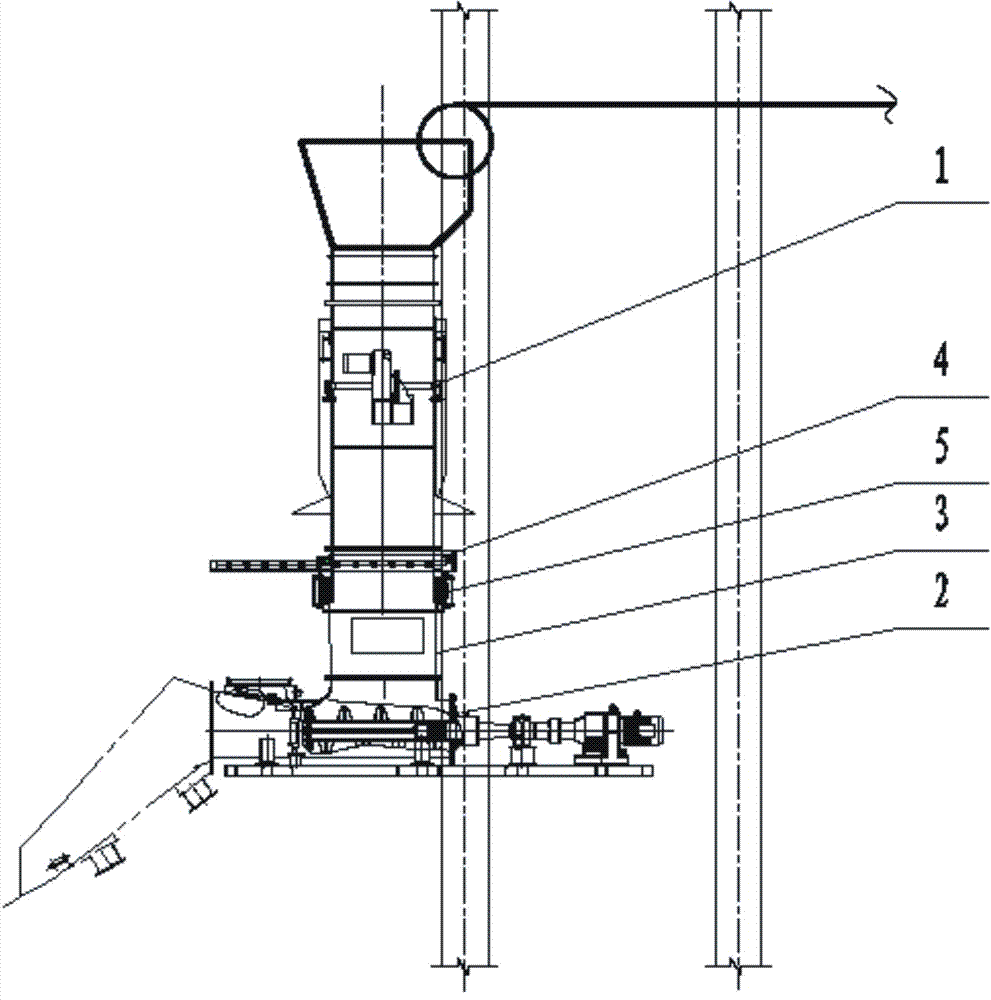

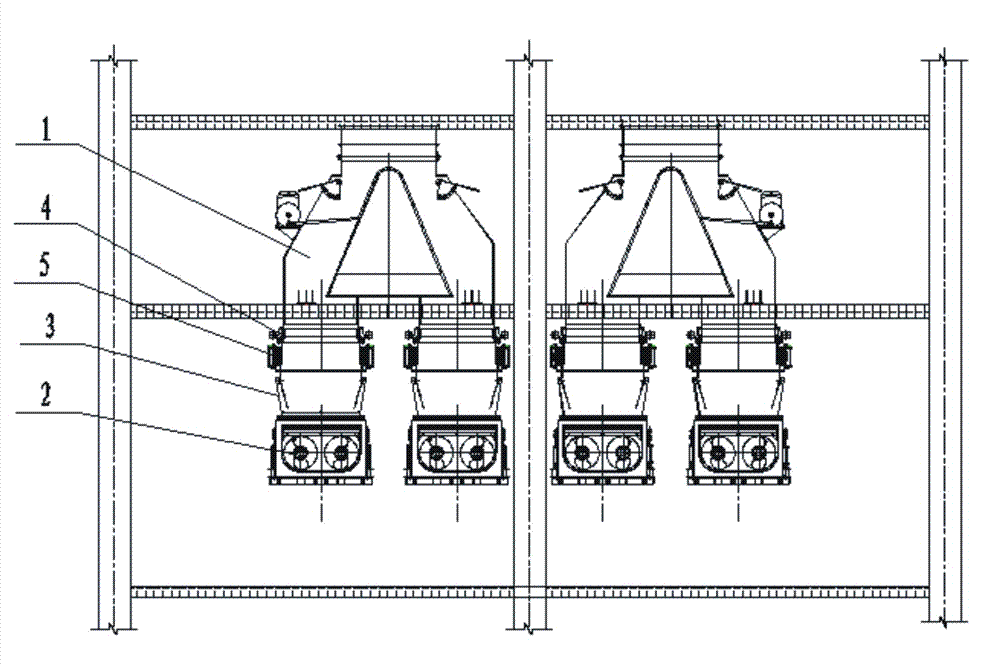

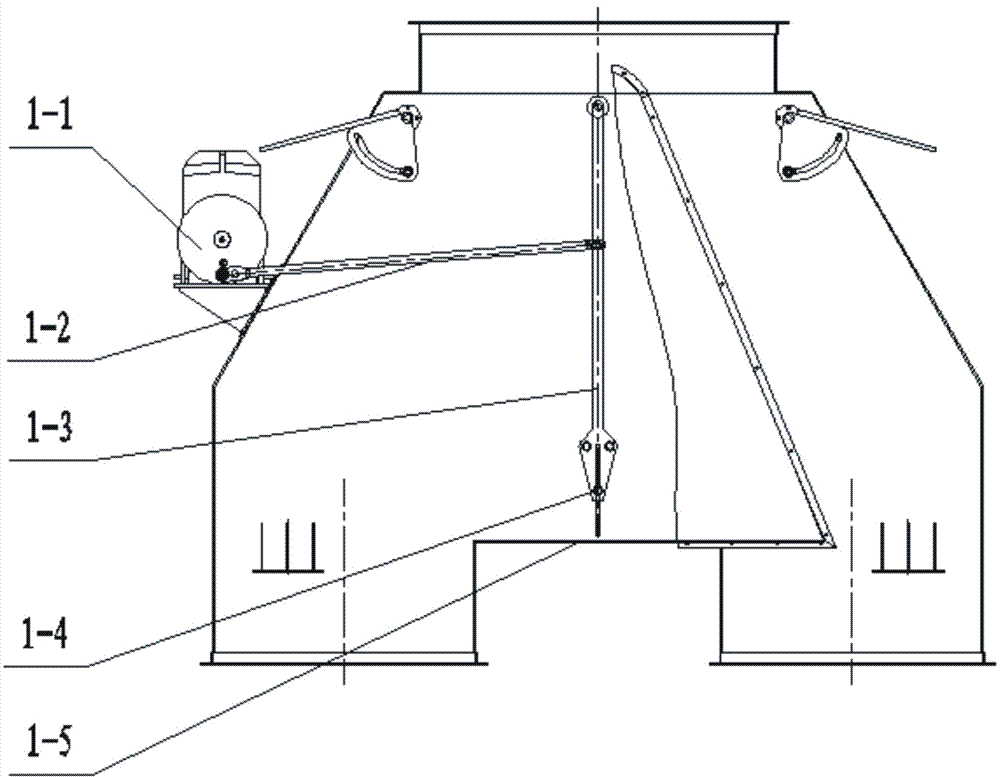

[0026] Such as figure 1 and figure 2 Shown: a biomass power plant without furnace feed bin feeding device, without furnace feed bin, mainly including feeder 1, screw feeder 2, feeder 1 and screw feeder 2 The drop tube 3. The feeding belt direct blanking method is adopted, one feeding belt corresponds to one feeder 1, one feeder 1 corresponds to two screw feeding devices 2, and four screw feeding devices 2 correspond to the four feeders of the boiler respectively. feed port. The fuel is transported to the front of the furnace by two feeding belts, and falls directly into the two distributors 1 respectively, and then directly falls into the four feeders through the drop pipe 3 between each outlet of the distributor 1 and the screw feeding device 2. A screw feeding device 2, and then from the screw feeding device 2 respectively enter the feeding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com