Optical component with stain resistant layer, and preparation method and application thereof

An optical component and anti-pollution technology, which is applied in optical components, optics, photovoltaic power generation, etc., can solve the problem of reducing the anti-reflection effect of the anti-reflection layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

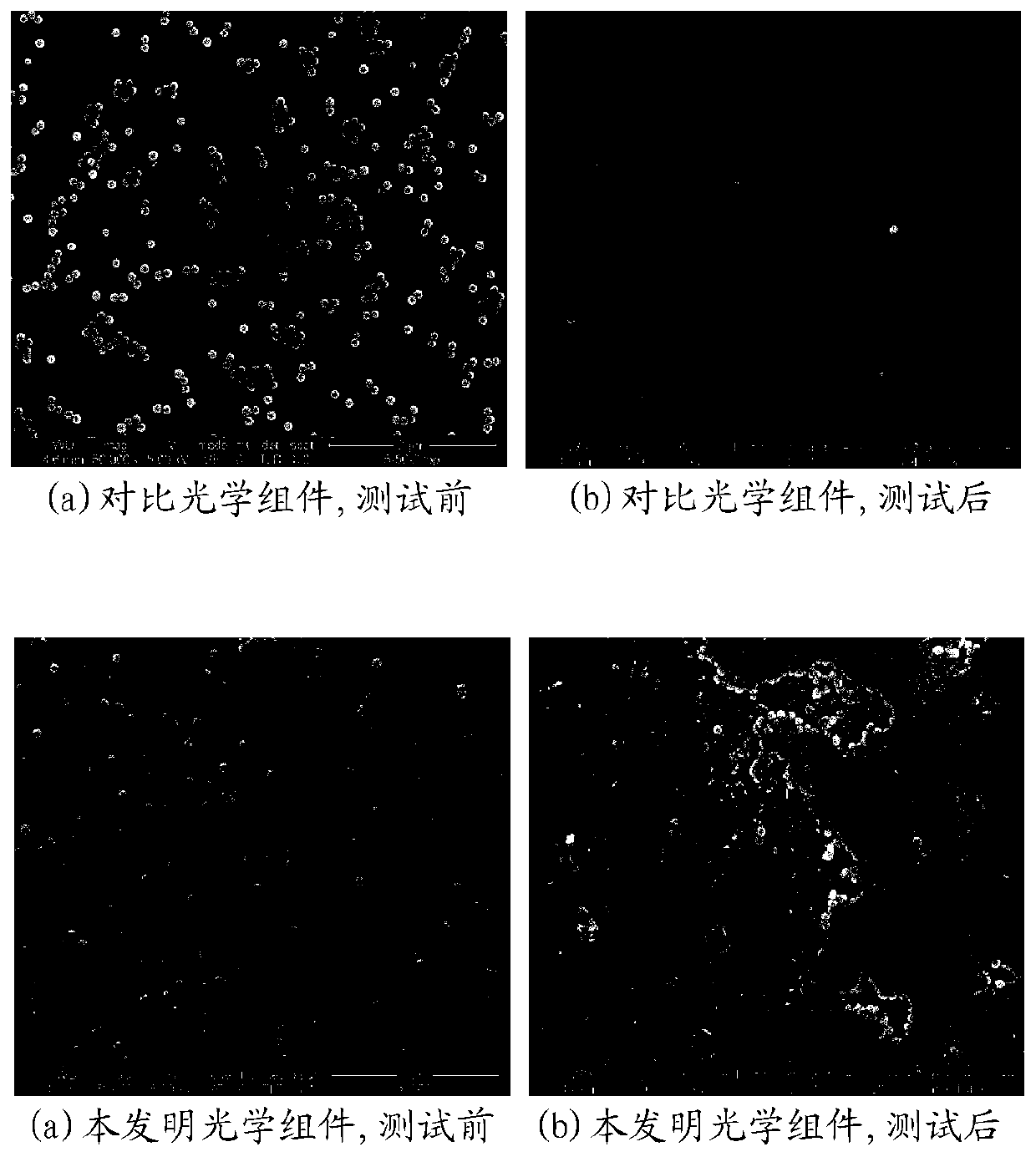

Examples

Embodiment 1

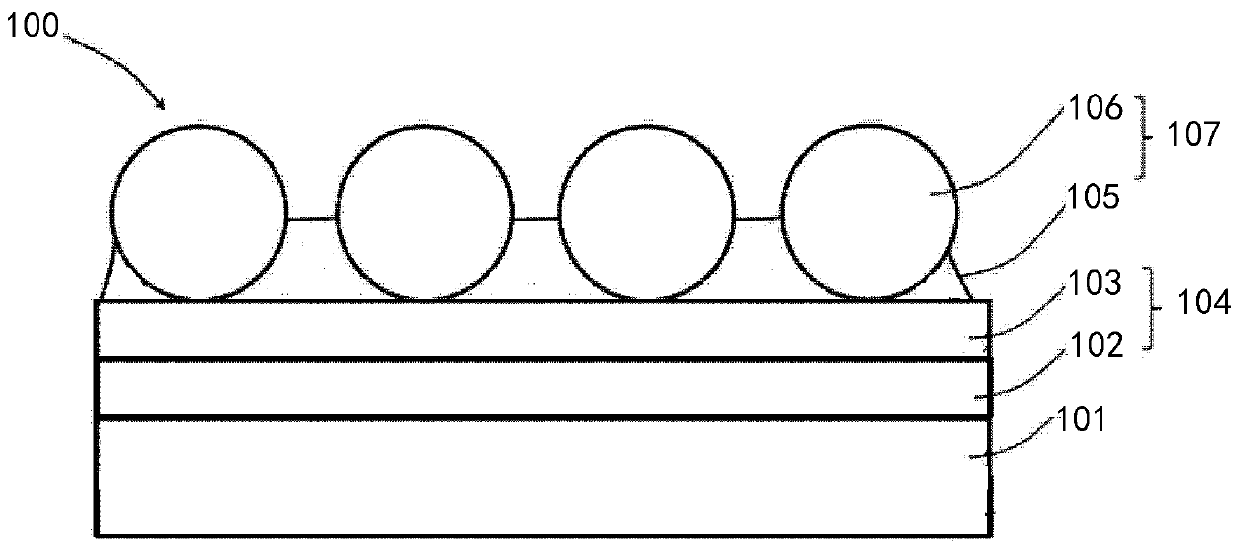

[0049] Anti-reflection coating

[0050] 500 g of a silica gel solution was prepared by mixing TEOS and an aqueous hydrochloric acid solution with a pH of 2 at a weight ratio of 1:1.5. An aqueous hydrochloric acid solution with a pH of 2 was further added to dilute to 2000 g. The resulting solution was deposited on a glass substrate with a spin coater at a speed of 1000 rpm. The coating was dried at 100° C. for 10 minutes to form a lower layer with a coating thickness of 50 nm.

[0051] 500 g of a silica gel solution was prepared by mixing TEOS and an aqueous hydrochloric acid solution with a pH of 2 at a weight ratio of 1:1.5. An aqueous hydrochloric acid solution with a pH of 2 was further added to dilute to 1850 g. 100 g of PMMA beads with a particle size of 50 nm were added to the solution, followed by 50 g of silica particles with a particle size of 100 nm. The resulting suspension was deposited on the lower layer using a spin coater at a speed of 1000 rpm. The coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com