Nanoscale precise displacement actuator for large segmented mirror optical telescope

A technology of large splicing and precision displacement, applied in optics, optical components, instruments, etc., can solve the problems of high cost, high unit price of flexible pivot, high processing cost, etc., achieve natural price, save purchase cost, save The effect of removing the milling processing fee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

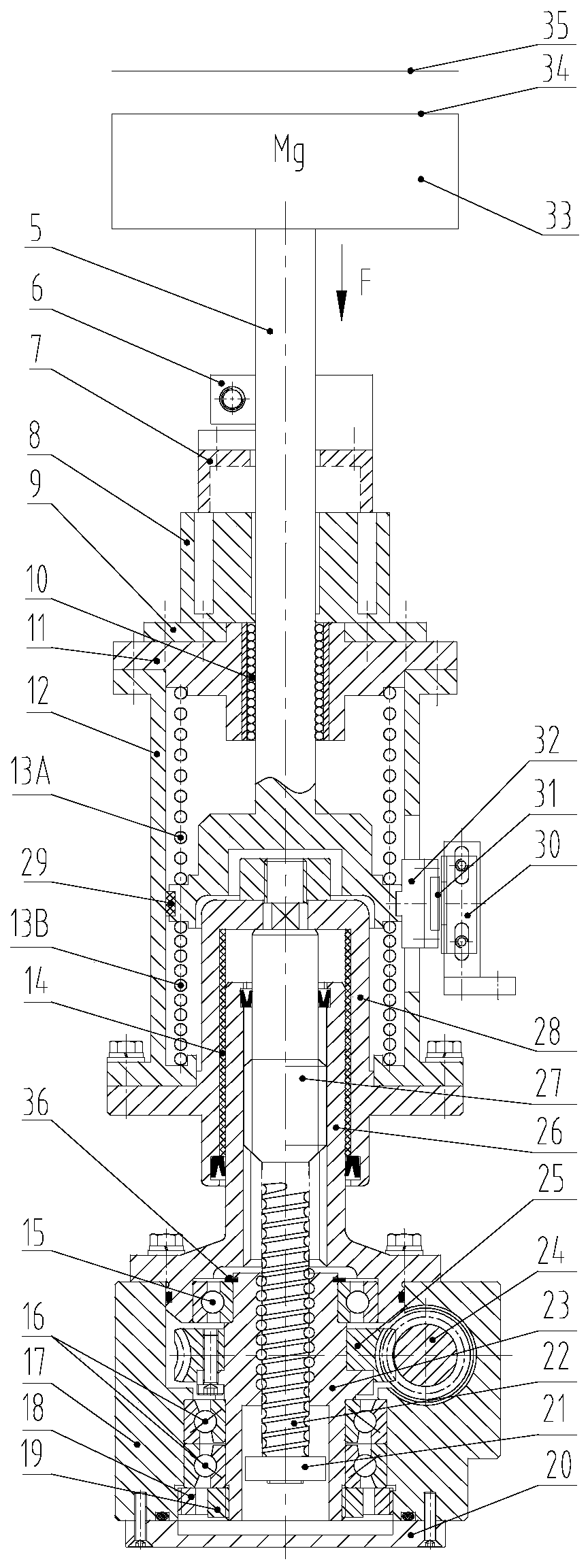

[0021] Embodiment 1, with reference to image 3 , the precision displacement actuator is driven by the motor to rotate the worm 24, the worm drives the worm wheel 25 to rotate, the worm wheel is fixed on the rotating nut 23 of the ball screw pair, the upper and lower ends of the rotating nut 23 are supported by bearings, and a set of back-to-back centripetal Thrust bearing 16, one side of the bearing outer ring is positioned on the shaft shoulder of the worm gear casing 17, the other side of the bearing outer ring is positioned and fixed by the outer ring compression nut 18, and the bearing inner ring side is close to the shaft shoulder of the rotating nut 23, The inner ring compression nut 19 is screwed on the external thread at the tail of the rotating nut 23, and is close to the inner ring of the bearing. By adjusting the tightening degree of the inner ring compression nut 19, the clearance between the two bearing rolling elements is eliminated, and the rotation nut 23 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com