Anti-resonance sound box

A resonant speaker and box board technology, applied in the direction of frequency/direction characteristic device, etc., can solve the problems of difficult handling, sound quality damage, and heavy quality of speakers, so as to avoid property loss, improve the vibration reduction effect, and facilitate the The effect of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

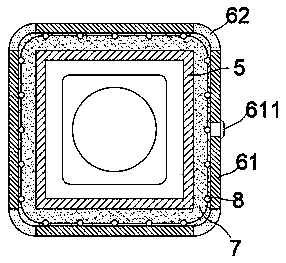

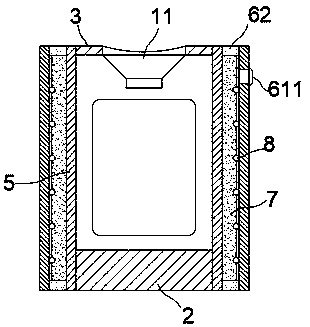

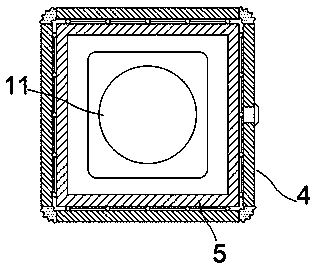

[0021] exist Figure 1 to Figure 3 In the shown embodiment, the anti-resonance sound box includes a power amplifier device, a speaker unit 11, a frequency divider, a fixing frame structure and a box body;

[0022] Described box body comprises base 2, top plate 3 and anti-vibration wall 4, and described anti-vibration wall 4 comprises deformation cover, is the case plate 5 of cylindrical shape; The two ends, the edges of the base 2 and the top plate 3 are fixedly connected with the inner wall of the box plate 5;

[0023] The deformation cover is arranged on the outside of the box plate 5,

[0024] Described deformable cover comprises shaping plate 61, flexible layer 62, and described shaping plate 61 is parallel to the board face of box plate 5, and is connected by flexible layer 62 between the side of adjacent shaping plate 61, and shaping plate 61 The upper side and the lower side are respectively connected to the outer wall of the box plate 5 through the flexible layer 62;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com