Large-particle crystallization device of ammonia process desulfurization and denitration system and using method of device

A technology of ammonia desulfurization and crystallization device, which is applied in the field of desulfurization and denitrification, can solve the problem of no filtration of intake air, and achieve the effects of ensuring intake air, increasing economic benefits, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

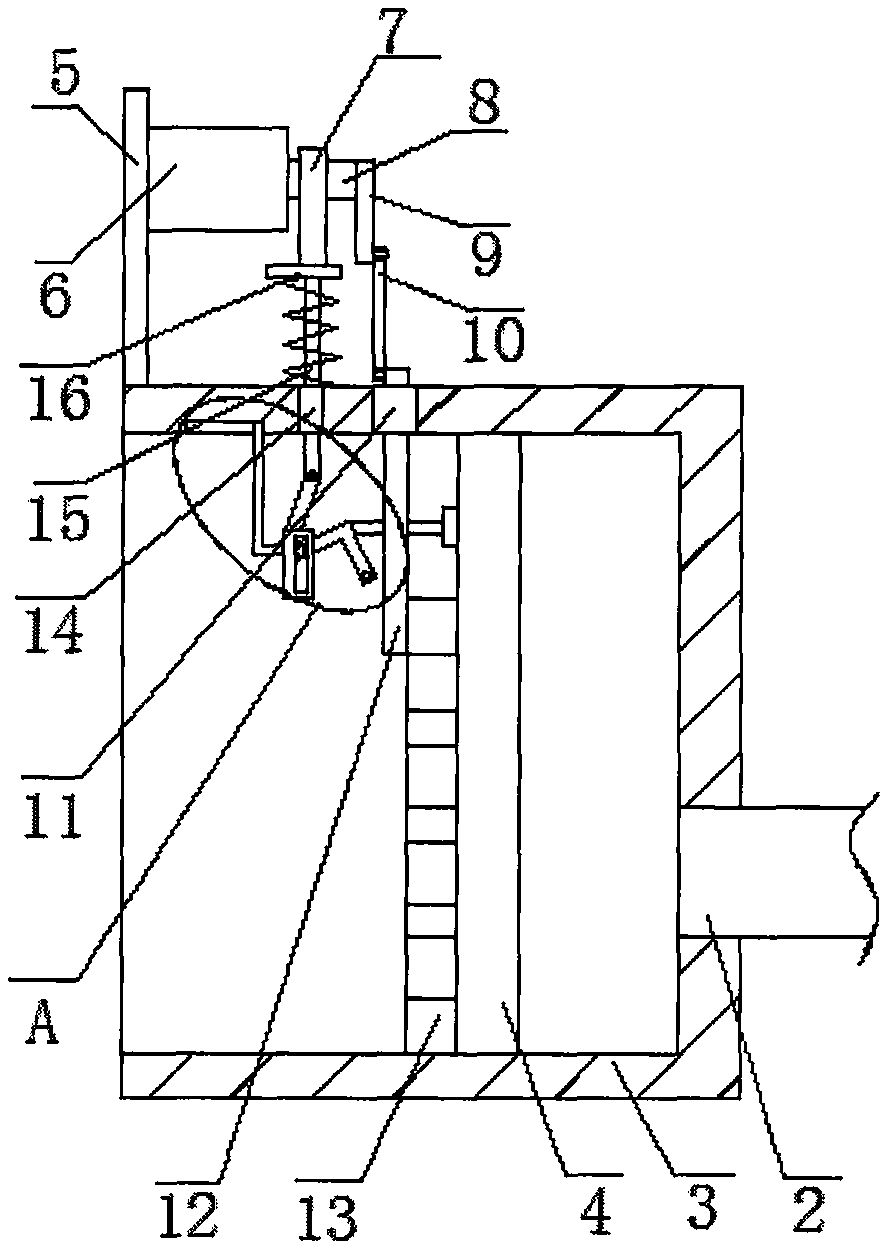

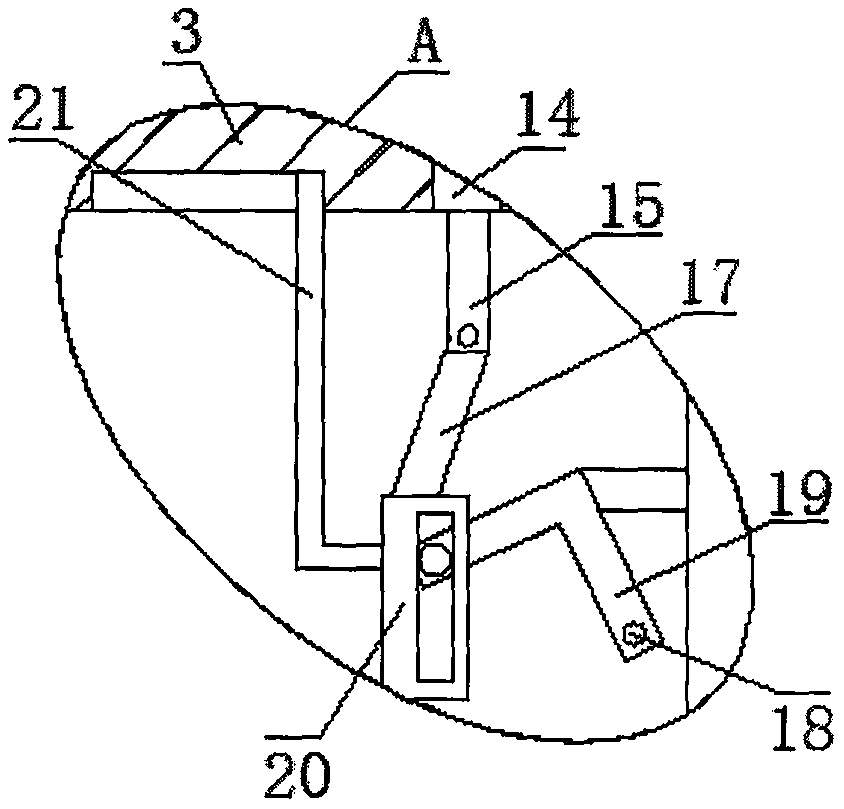

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

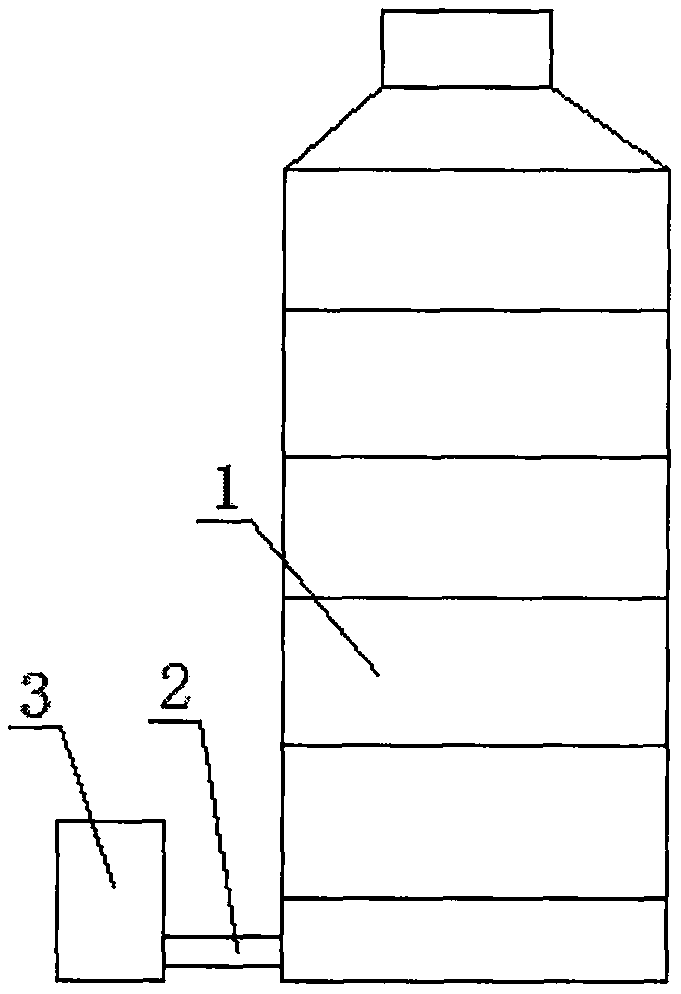

[0022] refer to Figure 1-3 , a large particle crystallization device of an ammonia desulfurization and denitrification system, comprising a tower body 1, an oxidation section, a concentration section, an absorption section, a purification water washing section and a demisting section are arranged in the tower body 1, and a demisting section is provided in the demisting section One side of the tower body 1 is provided with a filter box 3, and the side where the filter box 3 and the tower body 1 are close to each other is fixedly installed with the same air inlet pipe 2, and the two ends of the air inlet pipe 2 are respectively connected to the filter box 3 and the tow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap