Control method, device and system for additive manufacturing and storage medium

An additive manufacturing and control method technology, applied in the field of mechanical processing, can solve the problems of difficult to meet the precise control of laser molten pool solidification structure, difficult to achieve micro-scale precise control and customized distribution of mechanical properties, etc., to achieve a large degree of control freedom. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

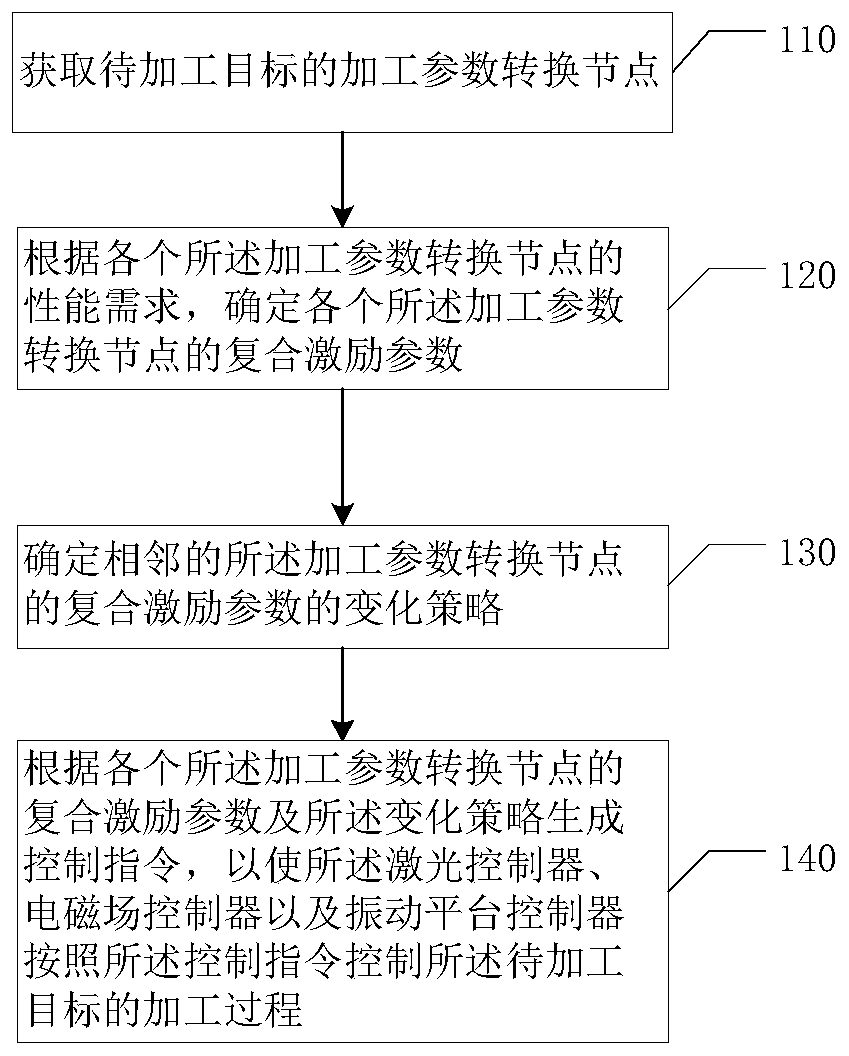

[0027] figure 1 It is a flow chart of a control method for additive manufacturing provided by Embodiment 1 of the present invention. This embodiment is applicable to the control of additive manufacturing technology. The method can be executed by a control device for additive manufacturing, specifically including Follow the steps below:

[0028] Step 110, acquiring the processing parameter transformation node of the object to be processed.

[0029] Wherein, the processing parameter conversion node refers to the node where the processing parameters of the object to be processed change. The number of processing parameter conversion nodes will vary with the target to be processed and its processing technology. It can be one, two, three or even more, mainly depending on the complexity of the processing technology.

[0030] Optionally, the processing parameter conversion node of the object to be processed can be determined through the processing technology and the processing route...

Embodiment 2

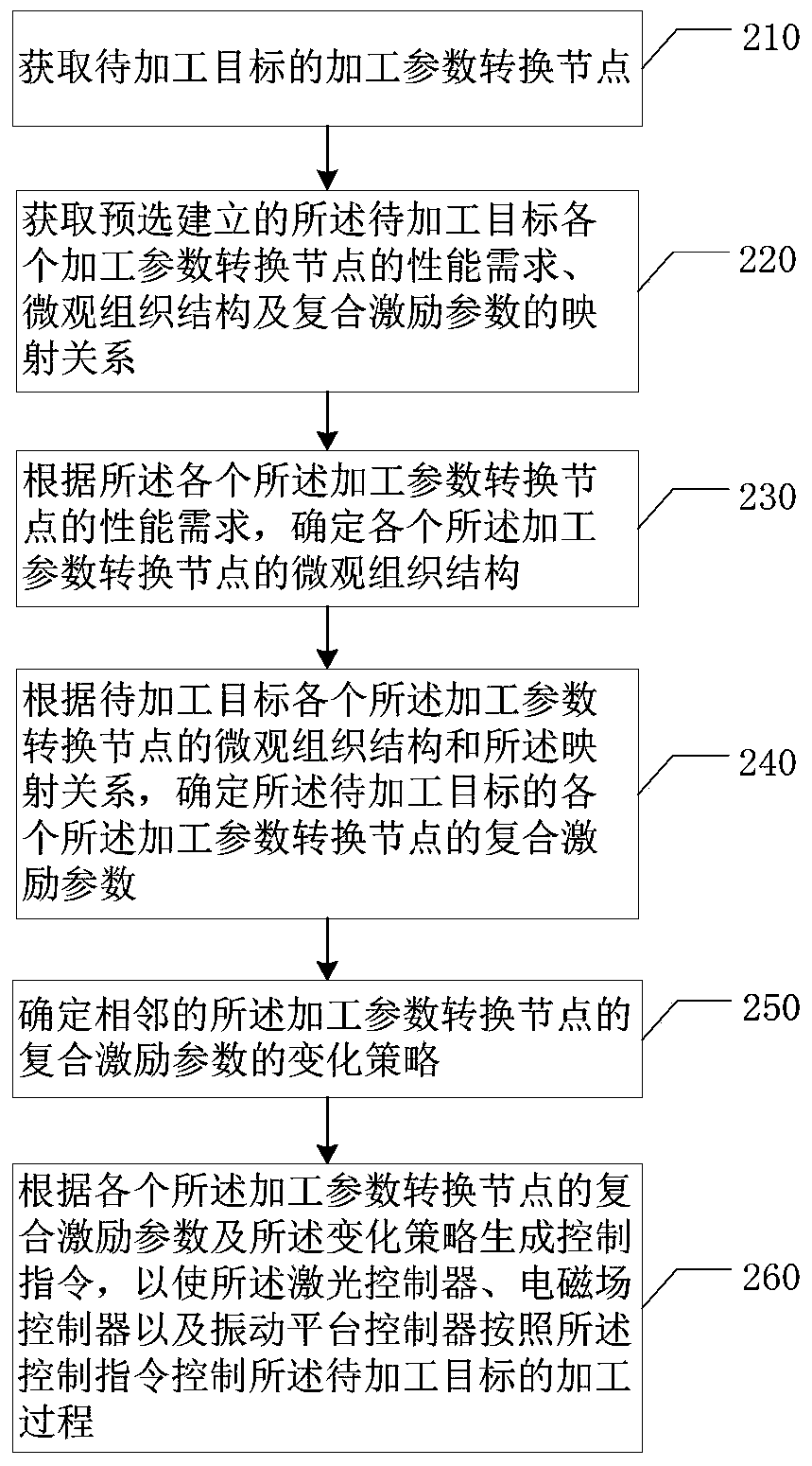

[0055] figure 2 It is a flow chart of a control method for additive manufacturing in Embodiment 2 of the present invention. The technical solution of this embodiment is supplemented on the basis of the above technical solution. Optionally, such as figure 2 As shown, the method for pushing preferential information provided by the embodiment of the present invention includes:

[0056] Step 210, acquiring the processing parameter transformation node of the object to be processed.

[0057] Step 220, obtaining the pre-selected and established mapping relationship between performance requirements, microstructure and compound excitation parameters of each processing parameter conversion node of the target to be processed.

[0058] Optionally, the above mapping relationship can be formulated by analyzing the material of the target to be processed, including the macroscopic and microscopic properties of the material, and through coupling analysis of the influence of each excitation ...

Embodiment 3

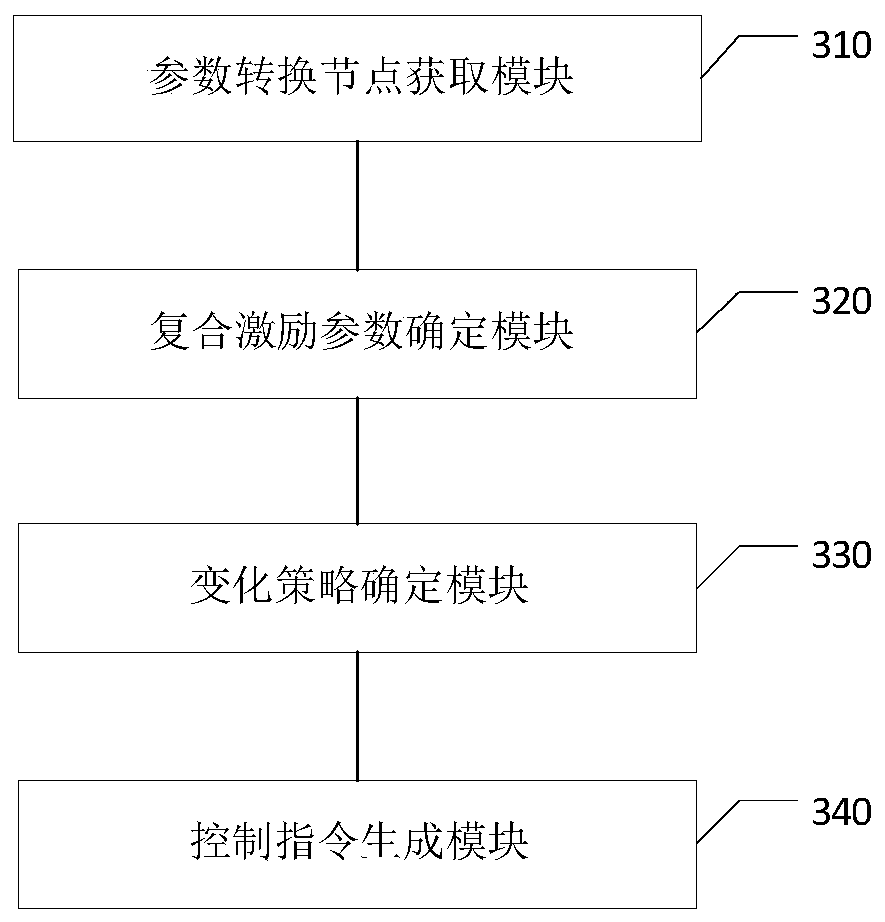

[0068] image 3 It is a schematic structural diagram of a control device for additive manufacturing in Embodiment 3 of the present invention, such as image 3 As shown, the control device for additive manufacturing includes: a parameter conversion node acquisition module 310 , a compound excitation parameter determination module 320 , a change strategy determination module 330 and a control command generation module 340 .

[0069] The parameter conversion node acquisition module 310 is used to obtain the processing parameter conversion node of the target to be processed; the composite excitation parameter determination module 320 is used to determine the composite of each processing parameter conversion node according to the performance requirements of each of the processing parameter conversion nodes. Excitation parameters, wherein the composite excitation parameters include laser excitation parameters, electromagnetic field excitation parameters and vibration platform excita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com