Tool and method for cleaning foreign matter on bolts

A foreign matter and bolt technology, which is applied in the direction of manufacturing tools, metal processing equipment, and grinding machine parts, etc., can solve the problems of consuming physical strength of construction workers, time-consuming and labor-intensive bolts, and delaying construction progress, etc., to achieve reasonable structure, strong applicability, The effect of firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

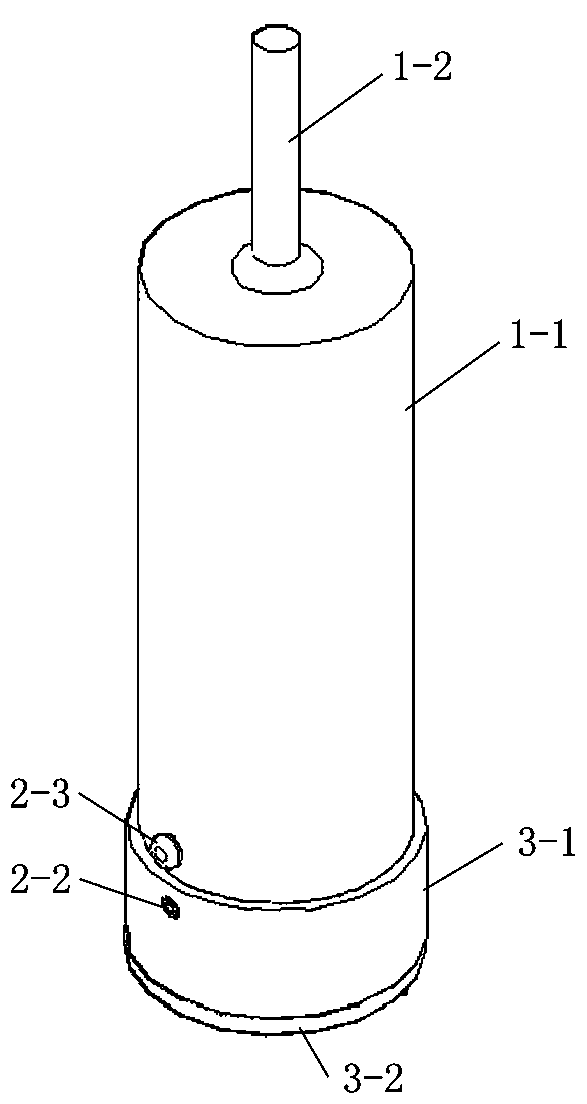

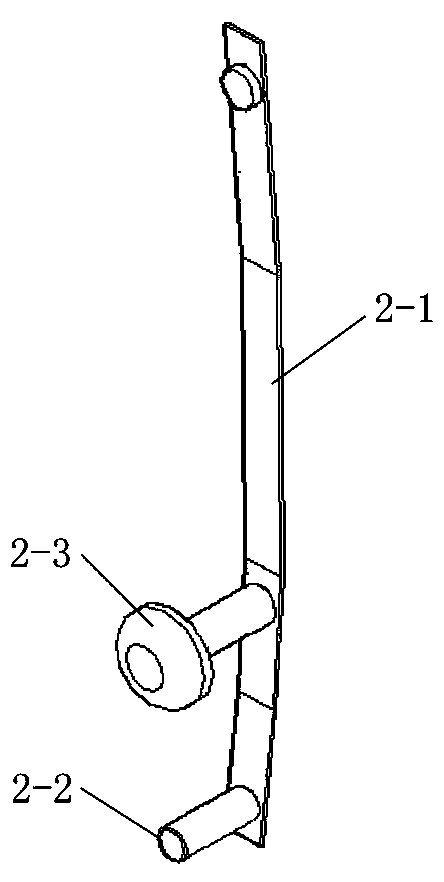

[0050] Such as Figure 1-Figure 6 As shown, the present invention discloses a tool for cleaning bolt foreign matter, including a rotating cylinder, a clamping mechanism and a grinding mechanism. The clamping mechanism is installed on the rotating cylinder, and the grinding mechanism is connected to the rotating cylinder through the clamping mechanism or separate.

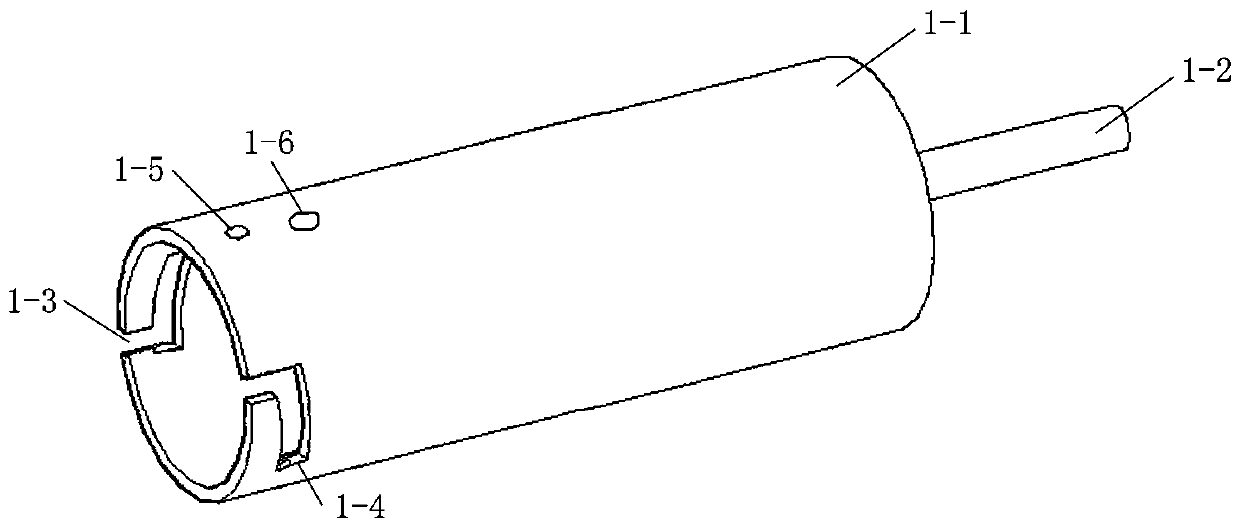

[0051] Such as figure 1 , figure 2 As shown, the drum includes a cylinder 1-1 and a connecting rod 1-2, one end of the cylinder 1-1 is fixedly connected with a closed cylinder bottom, the other end of the cylinder 1-1 is open, and the connection Rod 1-2 is fixedly connected on the outside of cylinder bottom.

[0052] Such as figure 2 As shown, a guide groove is provided at the opening of the cylinder 1-1, and the guide groove includes a first guide groove 1-3 and a second guide groove 1-4, and the first guide groove The grooves 1-3 have the same structure as the second guide grooves 1-4 and are evenly distrib...

Embodiment 2

[0061] Embodiment 2 is similar to Embodiment 1, except that a hand drill is added.

[0062] The invention discloses a tool for cleaning bolt foreign matter, which comprises a hand drill, a rotating cylinder, a clamping mechanism and a grinding mechanism. The clamping mechanism is installed on the rotating cylinder, and the grinding mechanism is connected to the rotating cylinder through the clamping mechanism or separate. The rotating cylinder is rotatably connected with the hand drill.

[0063] The drum includes a cylinder body 1-1 and a connecting rod 1-2, one end of the cylinder body 1-1 is fixedly connected with a closed cylinder bottom, the other end of the cylinder body 1-1 is open, and the connecting rod 1-1 2 fixedly connected to the outside of the cylinder bottom. The connecting rod 1-2 of the rotating cylinder is rotatably connected with the hand drill.

[0064] Such as figure 2 As shown, a guide groove is provided at the opening of the cylinder 1-1, and the gui...

Embodiment 3

[0073] The invention discloses a method for cleaning bolt foreign matter. The tool for cleaning bolt foreign matter is used and the following operations are performed: the grinding mechanism is clamped on the rotating cylinder through a clamping mechanism, and the connecting rod 1-2 of the rotating cylinder is inserted and fixed On the rotary head of the hand drill, the rotating cylinder is rotated by the hand drill, and the rotating cylinder drives the grinding mechanism to rotate, and the rotating grinding mechanism cleans the foreign matter on the bolts.

[0074] illustrate:

[0075] (1) Drum production

[0076] Findings: if Figure 7 Shown, need to clean thread length range 50mm to 160mm.

[0077] Such as Figure 8 As shown, by analyzing the "Investigation and Statistical Table of Anchor Bolt Models of Field Electrical Equipment", "Investigative Statistical Chart of Anchor Bolt Thread Length Needed to be Cleaned" and "Brush Head Size Table" in the prior art, we can get ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com