Circulation sterilization method for hot water device and hot water device

A technology of hot water equipment and sterilizer, which is applied in the direction of lighting and heating equipment, chemical instruments and methods, light water/sewage treatment, etc. It can solve problems such as health hazards and water quality impacts, and achieve sanitation of water flow, convenient installation and maintenance, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

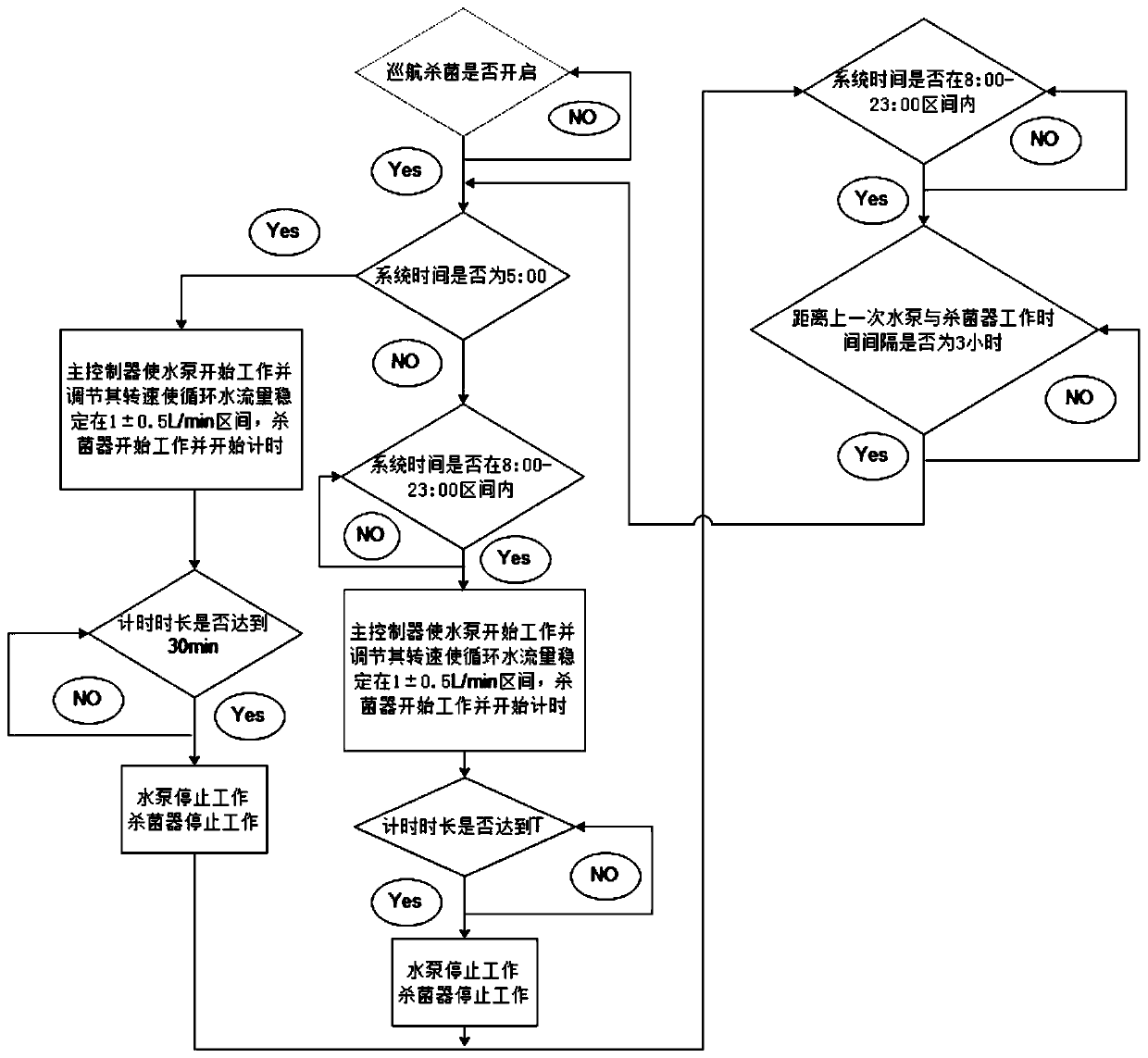

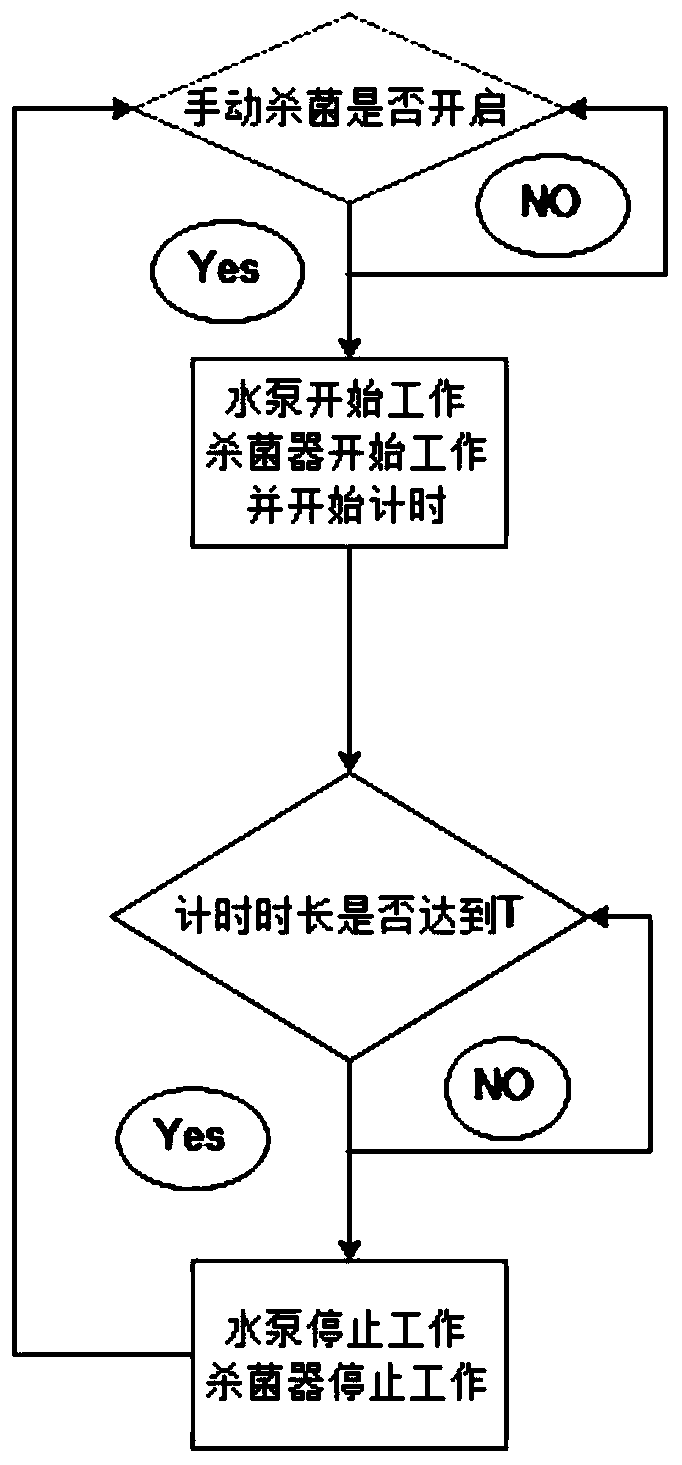

[0036] like figure 1 , figure 2 Shown is a cruising sterilization method for hot water equipment, which uses a circulating water pump to realize the water circulation of the water pipeline of the hot water equipment, uses an ultraviolet sterilizer to sterilize the water flow in the water pipeline, and uses a main controller to control the circulation The water pump and the ultraviolet sterilizer work; during sterilization, at least one of the following sterilization methods is included: 1) at the set time point, the circulating water pump and the ultraviolet sterilizer are controlled to run simultaneously for a first duration; 2) In the set time period, control the circulating water pump and the ultraviolet sterilizer to run simultaneously for a second duration every time interval; 3) Manually control the circulation of the circulating water pump and the ultraviolet sterilizer through the sterilization key Start and stop at the same time.

[0037] The manipulator connected ...

Embodiment 2

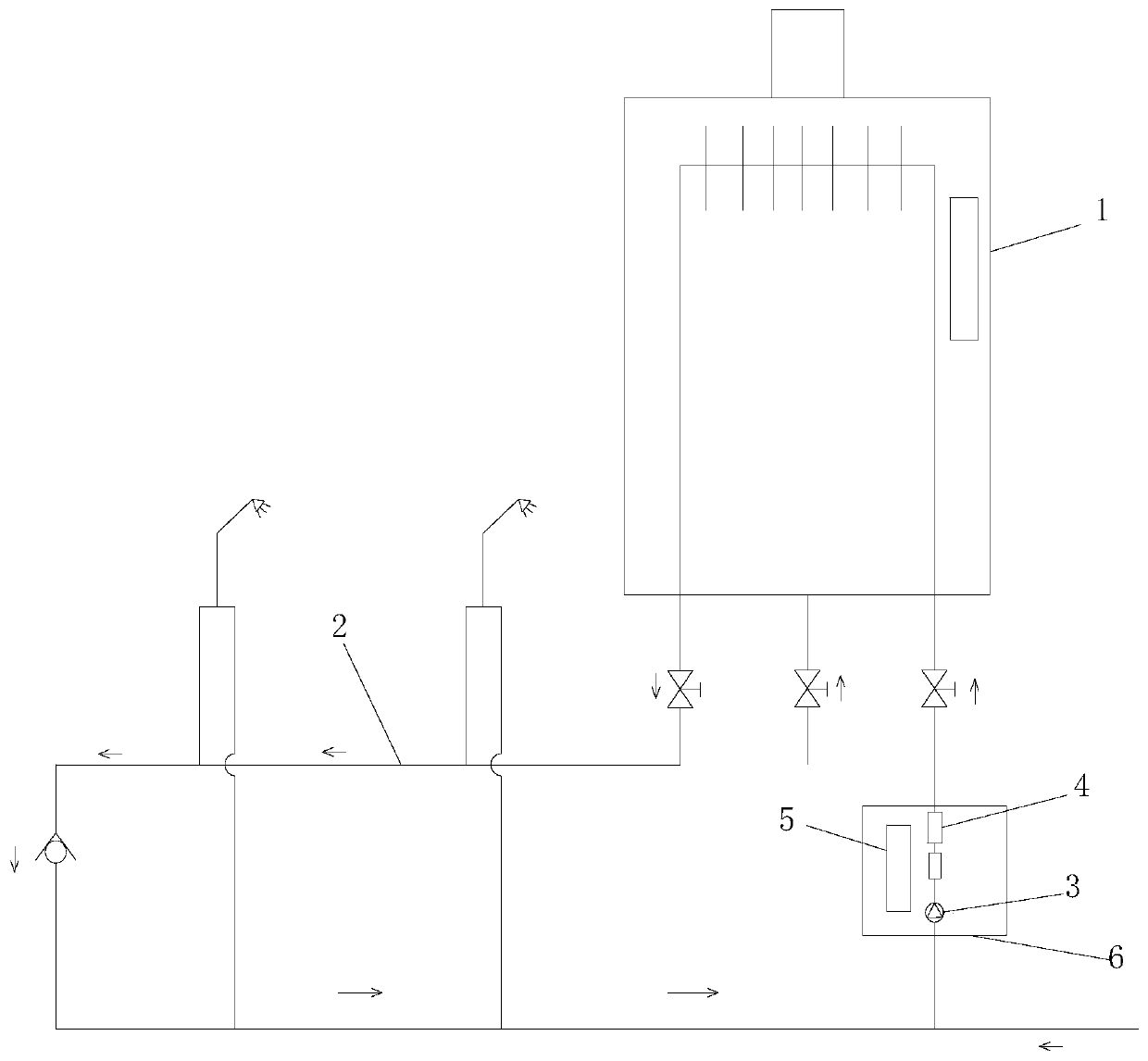

[0045] like image 3As shown, a hot water equipment includes: a water heater 1, a preheating circulation pipeline 2 connected to the water heater 1, and a circulating water pump 3 connected to the preheating circulation pipeline 2; The preheating circulation pipeline 2 is also provided with an ultraviolet sterilizer 4, and the circulating water pump 3 and the ultraviolet sterilizer 4 work simultaneously to sterilize under the control of the controller. The sterilizing method is as described in the first embodiment.

[0046] Wherein, the water heater 1 is a gas water heater, and the circulating water pump 3 , the ultraviolet sterilizer 4 and the controller 5 form an independent module 6 , and the module 6 is connected to the circulating pipeline 2 . By setting up an independent module, it can be used in combination with any hot water equipment that requires sterilization without changing the configuration of the original hot water equipment. It is easy to install and maintain, ...

Embodiment 3

[0048] like Figure 4 As shown, a hot water device, the structure of which is basically the same as that of Embodiment 2, the difference is that the circulating water pump 3 is arranged inside the gas water heater 1, and the ultraviolet sterilizer 4 is arranged outside the gas water heater 1, The controller is the main controller 7 of the gas water heater.

[0049] like Figure 5 As shown, as an alternative implementation of this embodiment, the circulating water pump 3 and the ultraviolet sterilizing device 4 are both arranged in the gas water heater 1, which is more beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com