Flowing-through type water sterilizing device and water purifying facility

A water sterilization and over-flow technology, which is applied in water/sewage treatment equipment, water/sewage treatment, light water/sewage treatment, etc. It can solve the problems of unstable sterilization rate, large randomness, and poor heat dissipation capacity of light source. , to achieve the effect of improving light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

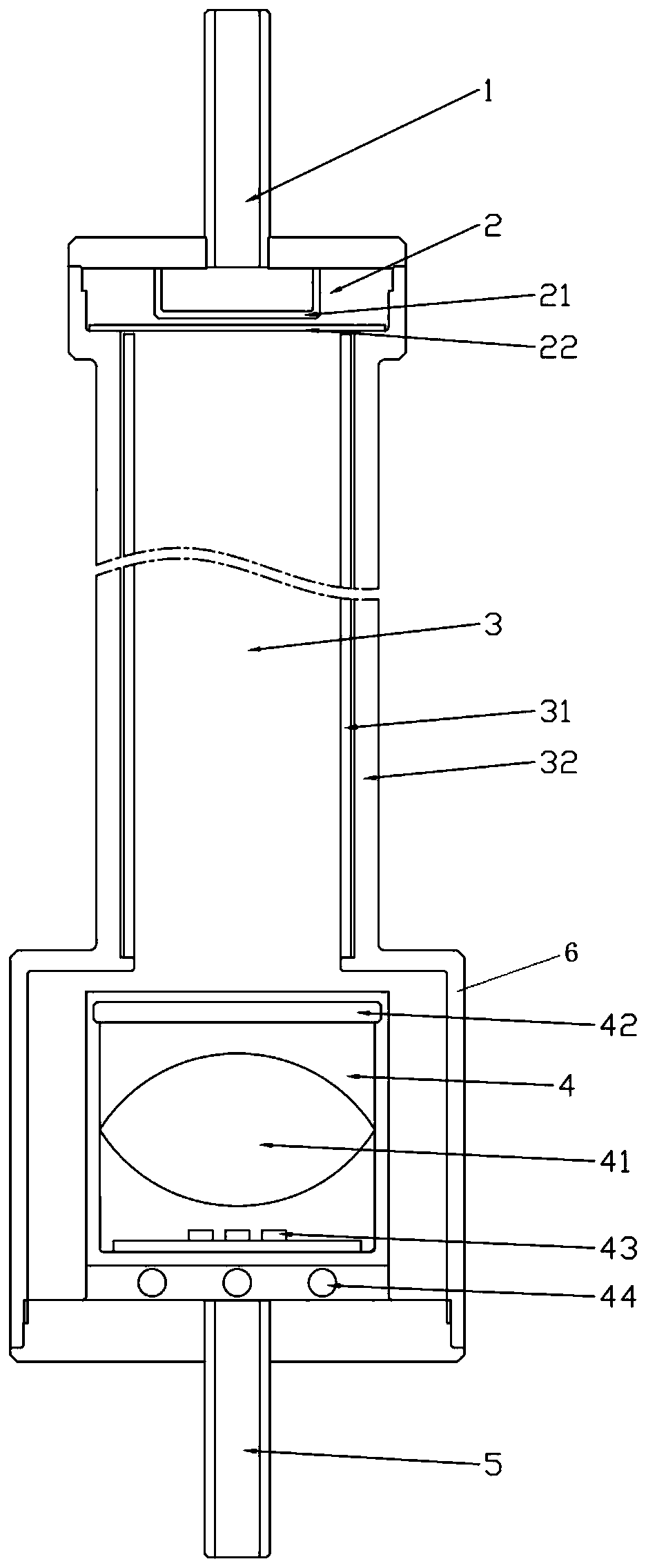

[0050] Such as figure 1 As shown, a flow-through water sterilization device includes a water inlet 1, a rectification module 2, a sterilization chamber 3, a UVC-LED light source assembly 4, a light source tube 6 and a water outlet 5, and the water inlet 1 and the rectification module 2 connection, the rectifier module 2 is connected to the inlet end of the sterilization chamber 3, the UVC-LED light source assembly 4 is located in the light source tube 6 and is located at the outlet end of the sterilization chamber 3, and the connection with the sterilization chamber 3 The outlet end is connected to the light source tube 6; the light source tube 6 is connected to the water outlet 5; the sterilizing cavity 3 includes a reflective sleeve 31 and a cavity shell 32, and the reflective sleeve and the cavity shell 32 are provided with The gap is filled with air, and the upper and lower ends of the gap are waterproofed with sealing rings.

[0051] The UVC-LED light source assembly 4 i...

Embodiment 2

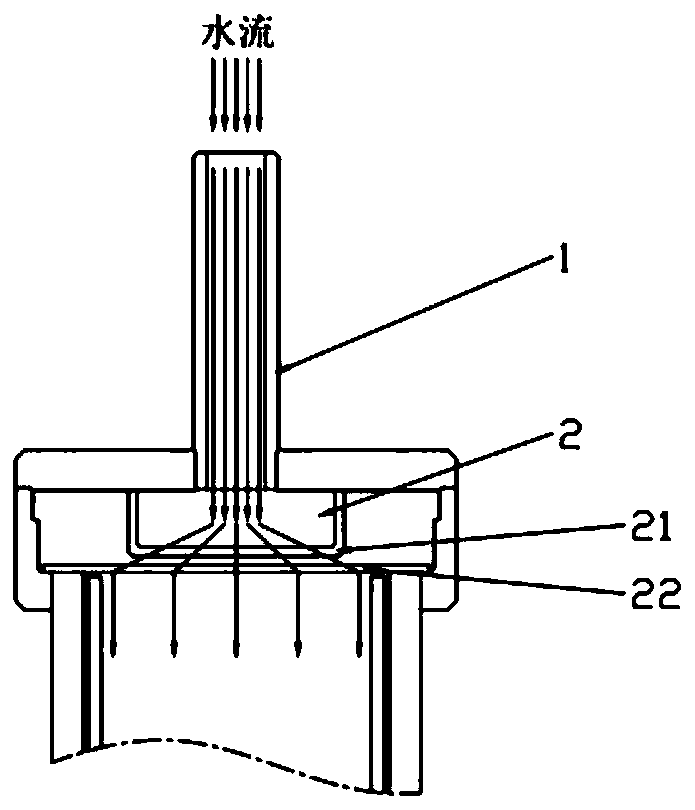

[0057] Such as figure 1 and figure 2 As shown, on the basis of Embodiment 1, the rectifying member includes a first rectifying member 21 and a second rectifying member 22, the second rectifying member 22 is located below the first rectifying member 21, and the first rectifying member 21 is a circular structure in the shape of a groove, the first rectification member 21 is coaxial with the water inlet 1, and several holes are opened on the first rectification member 21 to guide the flow. The first rectifying member 21 blocks and buffers the high-speed water flow at the inlet, and at the same time guides the water flow to spread and enter the second rectifying member 22 . The second rectifying member 22 is a circular perforated plate, the middle opening of the perforated plate is sparse, and the edge openings are dense. The water flow velocity at each position of the section remains consistent; it is beneficial to increase the sterilization time and sterilization stability. ...

Embodiment 3

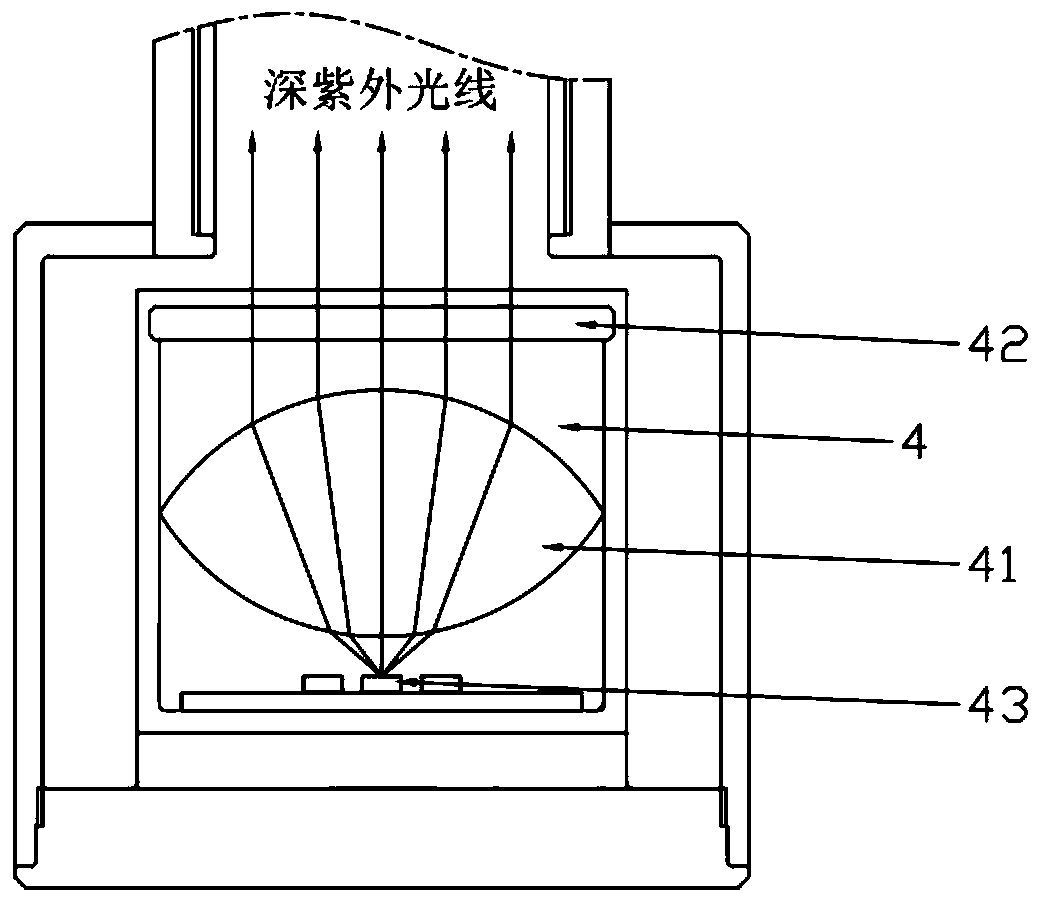

[0059] Such as figure 1 and image 3 As shown, on the basis of Embodiment 2, the optical lens includes a first optical lens 41 and a second optical lens 42, the second optical lens 42 is located above the first optical lens 41, and the first optical lens 41 is a fused silica lens with aspheric surfaces on both sides, the second optical lens 42 is a double-plane fused silica lens, the second optical lens 42 is located above the UVC-LED light source module 43, and the first optical lens 41 An air medium is provided between the second optical lens 42 and the second optical lens 42 . The distance between the UVC-LED light source module 43 and the first optical lens 41 is as short as possible to improve light utilization efficiency. Further, after the light passes through the first optical lens 41, the beam angle of the outgoing light is within 10°, and the cross-sectional light uniformity is above 90%.

[0060] The purpose of the second optical lens 42 is to transmit light and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com