Sizing device in double-feeding form for sizing machine

A technology of sizing device and sizing machine, which is applied in textile processing machine accessories, textile material processing, equipment configuration for processing textile materials, etc. It can solve problems such as blockage of sizing device, upside-down sizing, and insufficient sizing. Achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with example (accompanying drawing):

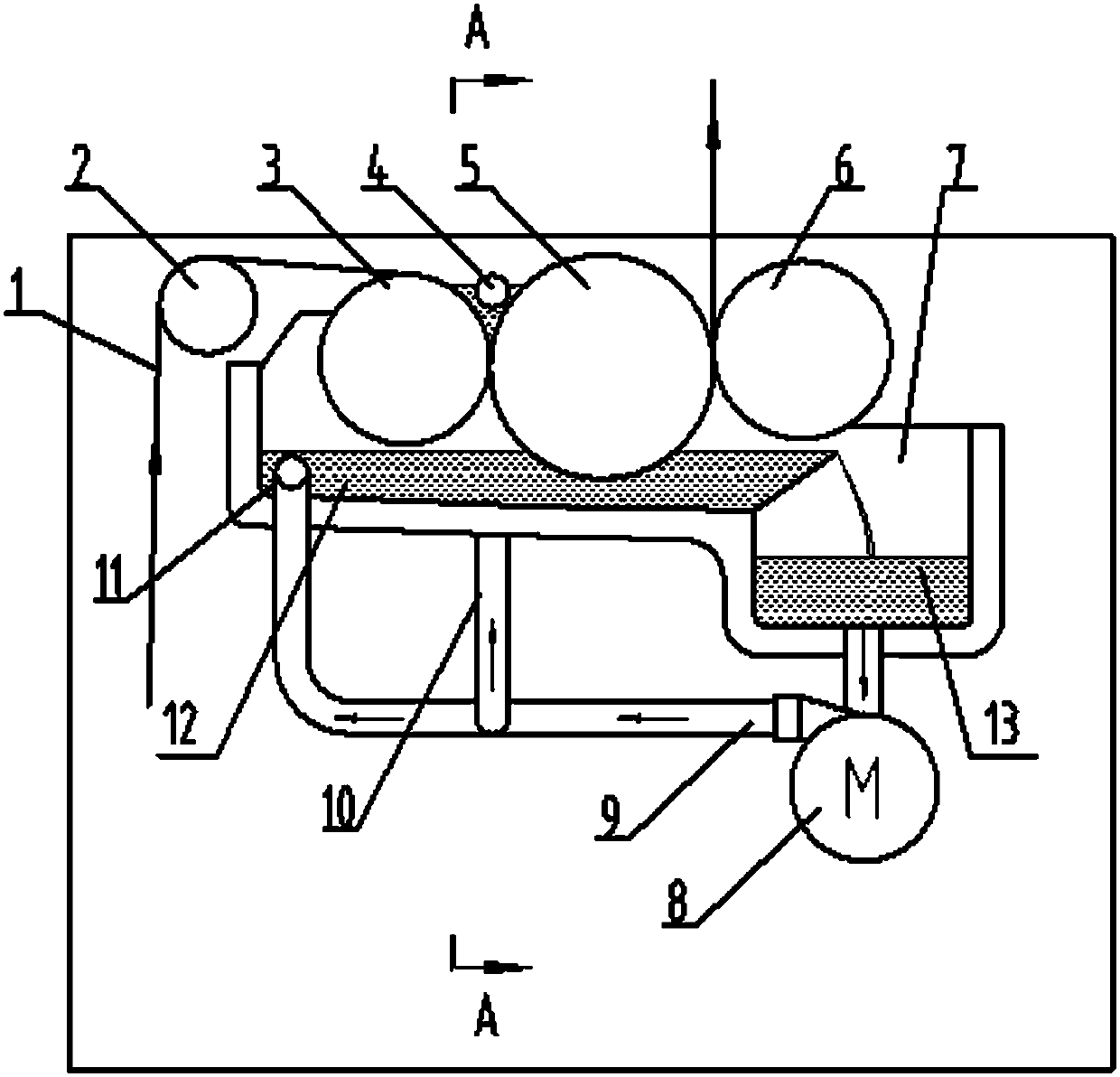

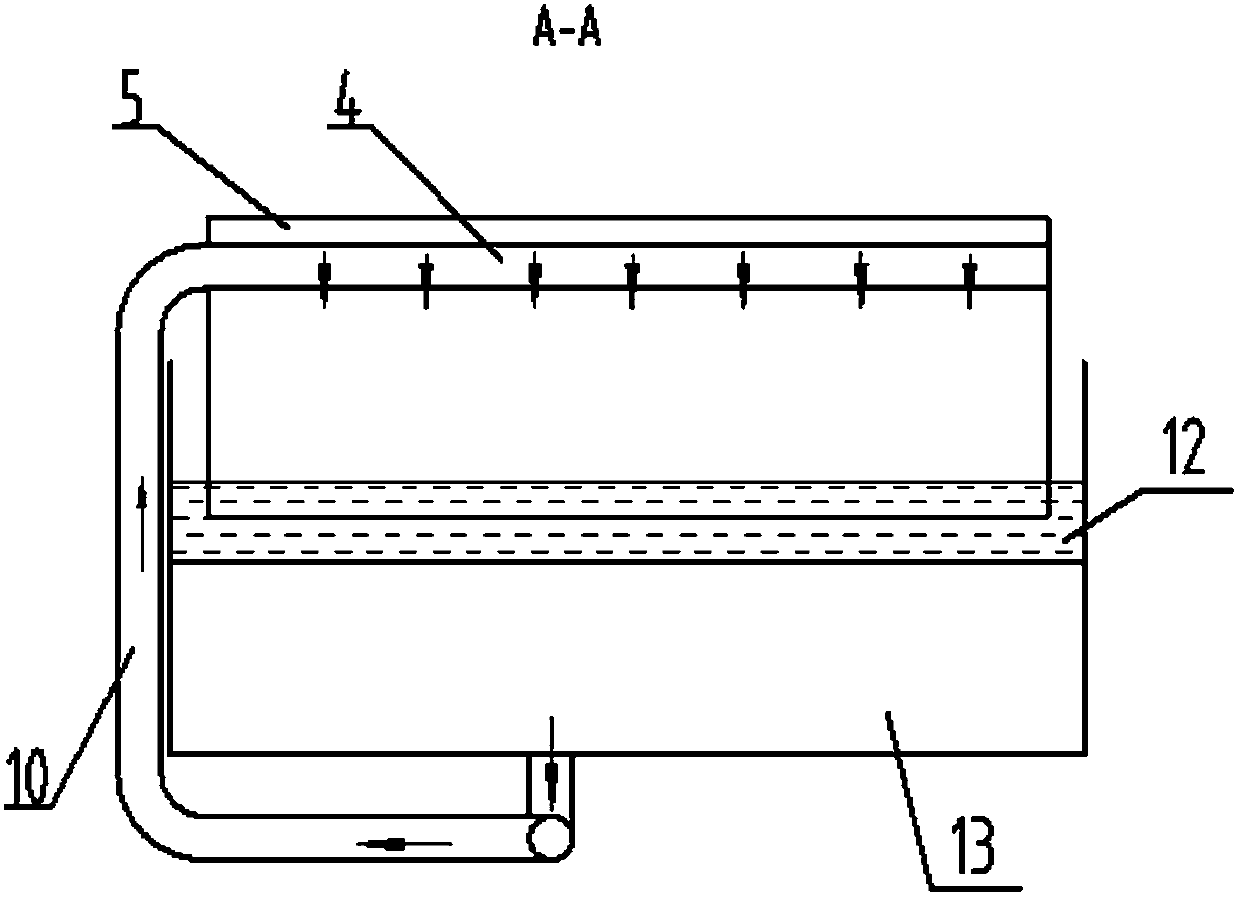

[0017] like figure 1 , 2 As shown, the sizing device of the present invention for the double-feed sizing form of the sizing machine includes a sizing tank 7 for holding the sizing liquid, and the first sizing tanks are sequentially arranged in the sizing tank according to the yarn advancing direction from back to front. Roller 3, sizing roller 5, the second squeeze roller 6, and the guide roller 2 that is positioned at the rear of the first squeeze roller 3 and the upper back of the size tank 7 for guiding the yarn 1 into the size tank; the size tank 7 includes The main stock tank 12 and the preheated stock tank 13 are arranged sequentially from back to front according to the flow direction of the slurry in the tank. The slurry outlet of the slurry delivery pipe 9 is connected, and the slurry outlet of the slurry delivery tube 9 is connected with the upper slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com