Antiskid wear-resistant color fog sealing layer material and construction process thereof

A fog seal material and color technology, applied to roads, pavement details, on-site coagulation pavement, etc., can solve the problems of high quality hidden dangers, difficult maintenance, single color and other problems, and achieve convenient maintenance and low engineering cost Low, exhaust gas reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

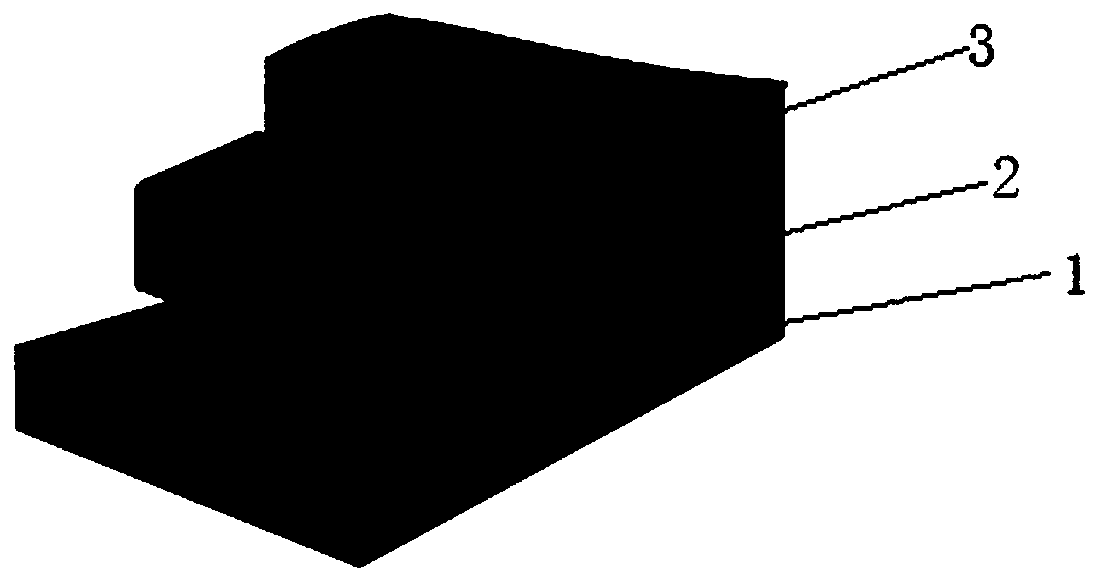

[0025] Such as figure 1 As shown, a non-slip and wear-resistant color fog seal material is constructed on the asphalt concrete base surface, including a colored waterproof bonding bottom layer 1, and a colored non-slip and wear-resistant intermediate layer 2 is scratch-coated on the waterproof bonding bottom layer 1. The color weather-resistant protective surface layer 3 is rolled on the middle layer 2 .

[0026] In this embodiment, the colored waterproof adhesive bottom layer is mainly directly rolled or sprayed with high-viscosity colored composite emulsion.

[0027] In this embodiment, the colored anti-slip and wear-resistant intermediate layer is mainly rolled by a waterproof asphalt mixed mortar prepared by mixing 6 parts by weight of high-viscosity colored composite emulsion, 12 parts of high-stiffness mixed additives and 1 part of water or spray.

[0028] In this embodiment, the surface protective agent in the colored weather-resistant protective surface layer is a mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com