Sludge geology release hole sand filling device and method

A technology of releasing holes and filling sand, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of release hole failure, water resistance infiltration of mud, and excessive pore diameter, and achieve good economic benefits and social benefits. efficiency, improving the bearing capacity of the foundation, and speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in detail below with reference to accompanying drawing and embodiment:

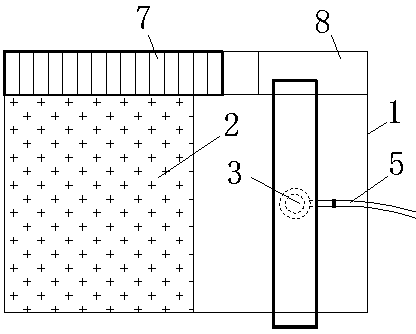

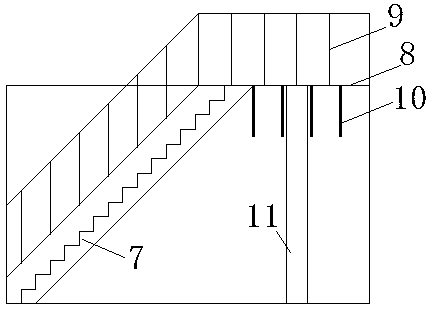

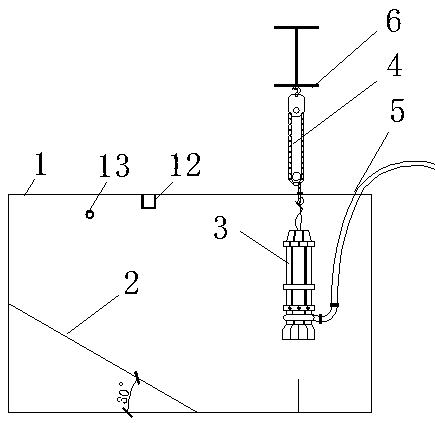

[0047] attached Figure 1-6 It can be seen that a sand filling device for silt geological release holes includes:

[0048] Use steel plates to weld the box body 1 and the steel slope 2;

[0049] A shaped steel column 11 is arranged on the box body 1, and a main beam 6 and an electric hoist ring on the main beam are arranged on the top of the column;

[0050] A steel ladder 7, a platform 8, and platform legs 10 are provided on the box body 1;

[0051] A sand suction pump 3 is arranged in the box body 1;

[0052] Connect the conveying pipeline 5 to the water outlet of the sand suction pump 3, and use the electric hoist 4 to suspend the sand suction pump 3 into the box body 1;

[0053] The box body 1 is provided with a water inlet 13 .

[0054] The top of the box body 1 is welded with steel tie rods.

[0055] A sand filling method for a sand filling device in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com