A bridge damping expansion joint

A technology of expansion joints and bridges, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as spring performance degradation, shock absorption performance discount, impact on driving speed, comfort and safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

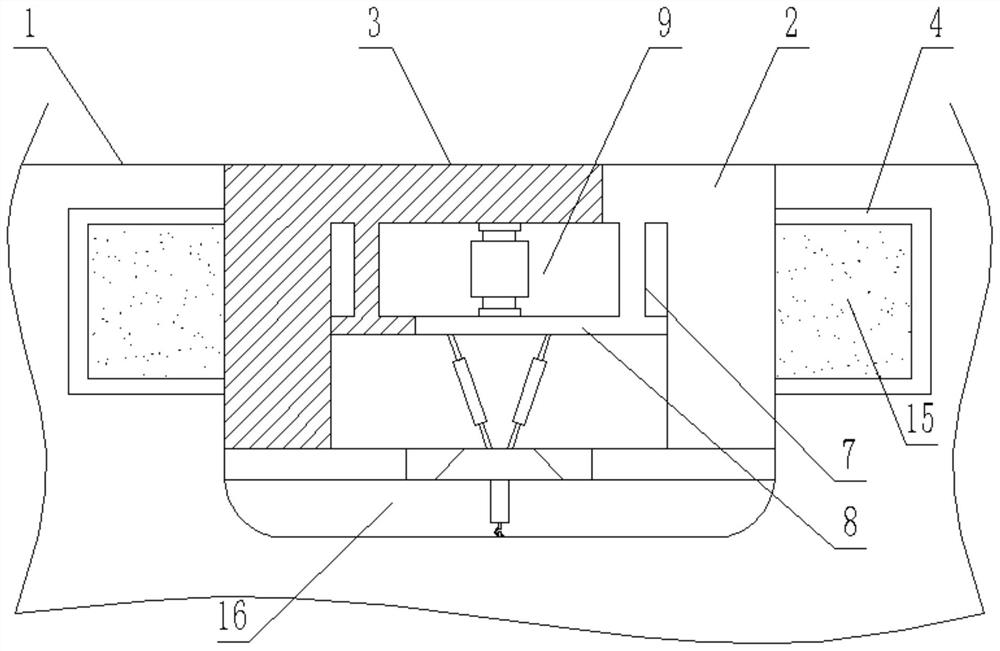

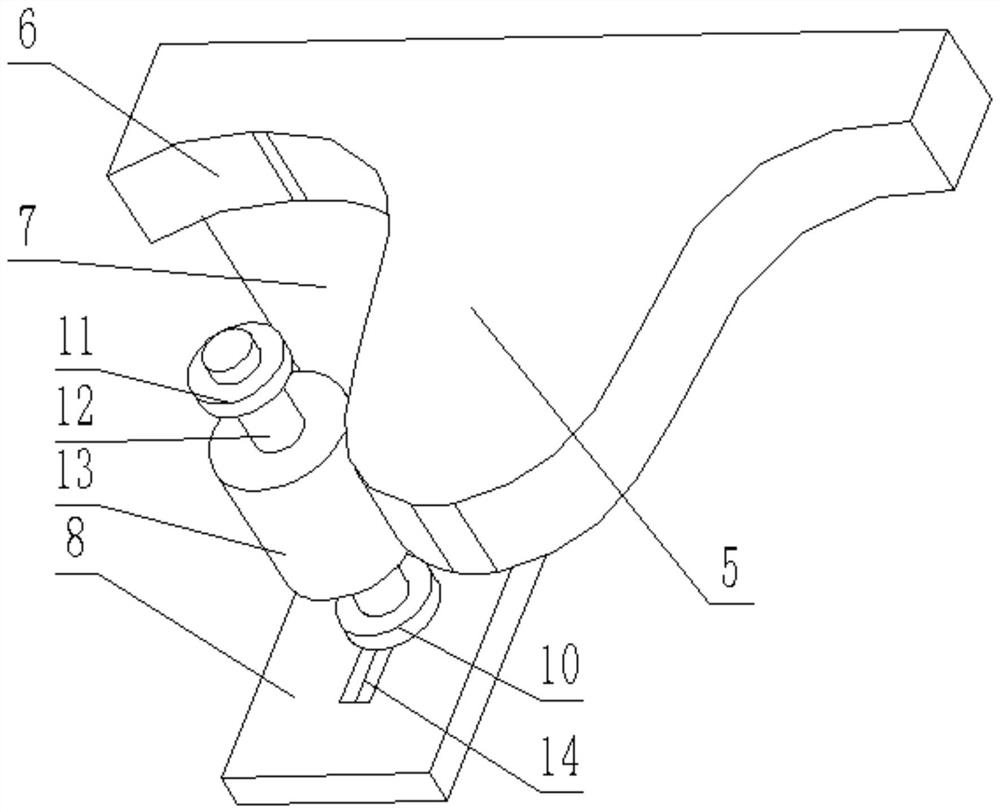

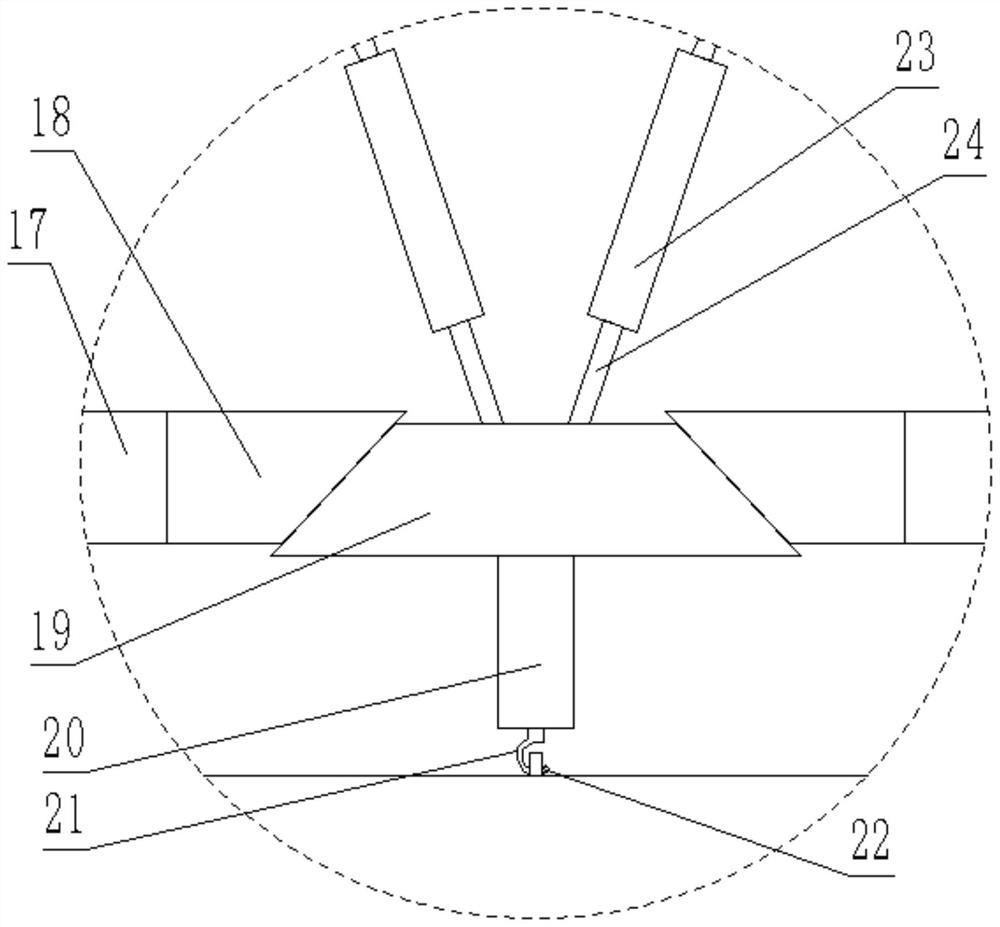

[0019] see Figure 1-3 , a bridge shock-absorbing expansion joint, including a square groove-shaped seam body and a buffer shock-absorbing structure located in the seam body, the buffer shock-absorbing structure includes a right corrugated frame 2 and a left corrugated frame 3 located on both sides of the seam body, and the right corrugated frame 2 and the left corrugated frame 3 have the same shape and structure and are staggered on the same horizontal plane. The upper plane of the corrugated frame is flush with the top surface of the bridge body 1. Protrusions 5 and depressions 6 are arranged at intervals. The protrusions 5 are used to insert into the depressions 6 on the opposite corrugated frame, so as to maintain the stability of the seam structure when the seam is deformed. The front end of the protrusions 5 and the depression The tail ends of the parts 6 are all arc-shaped, and a parallel plate 8 arranged parallel to the protruding part 5 is arranged below the concave p...

Embodiment 2

[0022] On the basis of Example 1, the steel bar 4 is sealed and docked with the back of the corrugated frame to form a "mouth"-shaped cavity, and the cavity is filled with sound-absorbing cotton 15. The collision produces vibration, and the vibration is transmitted to the sound-absorbing cotton 15 through the corrugated frame and the steel bar 4, and the sound-absorbing cotton 15 eliminates the noise generated by the vibration, and then also plays a certain elimination effect on the vibration.

Embodiment 3

[0024] On the basis of Example 1, there is a gap between the vertical plate 7 and the corresponding vertical surface of the corrugated frame, and the side of the parallel plate 8 at the bottom of the vertical plate 7 is attached to the vertical surface of the corrugated frame and is not fixed. This design ensures that the parallel plate 8 can vibrate differently from the corrugated frame when it is vibrated, so as to avoid the resonance effect of the buffer and shock-absorbing structure, thereby further improving the safety of the overall device and the bridge body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com