Multi-core-layer inorganic mineral insulation flexible fireproof cable and preparation method thereof

A technology of inorganic minerals and fireproof cables, which is applied in the manufacture of insulating cables, inorganic insulators, and cables/conductors, and can solve problems such as low efficiency, long mixing time, and inconvenient discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

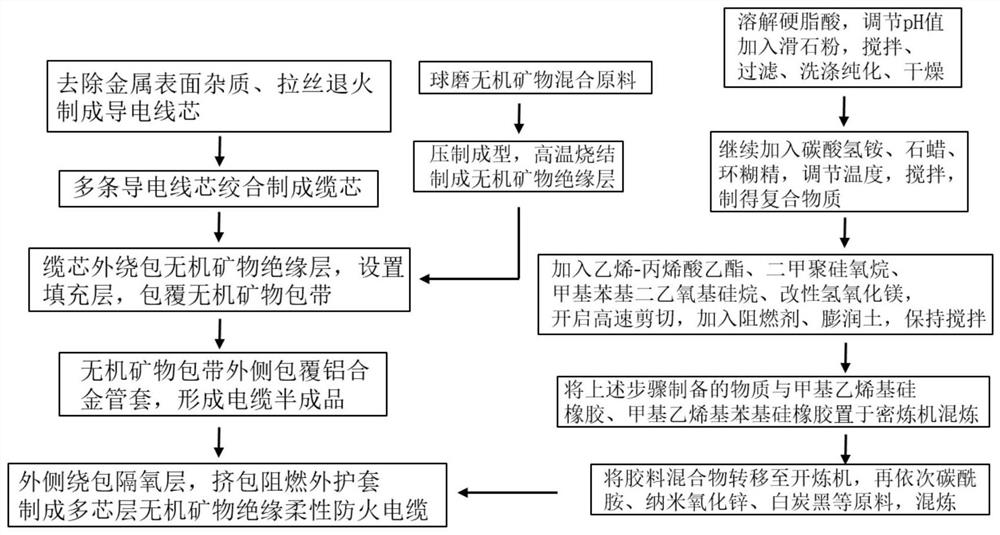

[0105]S1. Remove impurities on the metal surface, straighten after drying, wire drawing and annealing to make conductive wire core,

[0106] A plurality of conductive wire cores are stranded to make a cable core;

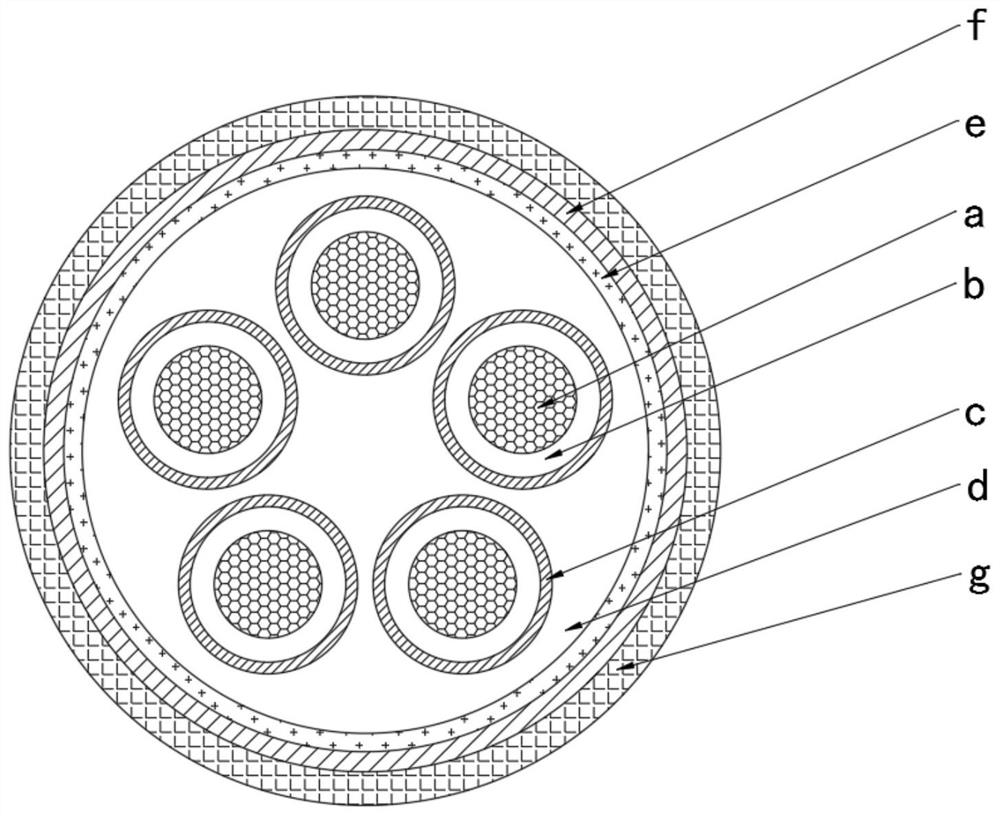

[0107] S2. Wrapping an inorganic mineral insulating layer outside the cable core, setting a filling layer between multiple cable cores, and then continuing to coat the outer layer with an inorganic mineral tape;

[0108] S3. Extrude the aluminum alloy tube through the aluminum tube extrusion machine, and coat the aluminum alloy tube sleeve on the inorganic mineral tape to form a semi-finished cable;

[0109] S4. Wrap an oxygen barrier layer on the outer side of the semi-finished cable, and finally extrude a flame-retardant outer sheath on the outer side to make a multi-core inorganic mineral insulated flexible fireproof cable.

[0110] Wherein, the preparation steps of the inorganic mineral insulating layer used in step S2 are as follows:

[0111] (1) In terms of ...

Embodiment 2

[0129] S1. Remove impurities on the metal surface, straighten after drying, wire drawing and annealing to make conductive wire core,

[0130] A plurality of conductive wire cores are stranded to make a cable core;

[0131] S2. Wrapping an inorganic mineral insulating layer outside the cable core, setting a filling layer between multiple cable cores, and then continuing to coat the outer layer with an inorganic mineral tape;

[0132] S3. Extrude the aluminum alloy tube through the aluminum tube extrusion machine, and coat the aluminum alloy tube sleeve on the inorganic mineral tape to form a semi-finished cable;

[0133] S4. Wrap an oxygen barrier layer on the outer side of the semi-finished cable, and finally extrude a flame-retardant outer sheath on the outer side to make a multi-core inorganic mineral insulated flexible fireproof cable.

[0134] Wherein, the preparation steps of the inorganic mineral insulating layer used in step S2 are as follows:

[0135] (1) In terms of...

Embodiment 3

[0153] S1. Remove impurities on the metal surface, straighten after drying, wire drawing and annealing to make conductive wire core,

[0154] A plurality of conductive wire cores are stranded to make a cable core;

[0155] S2. Wrapping an inorganic mineral insulating layer outside the cable core, setting a filling layer between multiple cable cores, and then continuing to coat the outer layer with an inorganic mineral tape;

[0156] S3. Extrude the aluminum alloy tube through the aluminum tube extrusion machine, and coat the aluminum alloy tube sleeve on the inorganic mineral tape to form a semi-finished cable;

[0157] S4. Wrap an oxygen barrier layer on the outer side of the semi-finished cable, and finally extrude a flame-retardant outer sheath on the outer side to make a multi-core inorganic mineral insulated flexible fireproof cable.

[0158] Wherein, the preparation steps of the inorganic mineral insulating layer used in step S2 are as follows:

[0159] (1) In terms of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com