A prefabricated building composite exterior wall panel structure

A technology of composite exterior wall panels and assembly panels, which is applied to building components, building structures, buildings, etc., can solve problems such as loosening, affecting construction progress, troublesome maintenance and replacement, etc., to achieve fast decoration, improve work efficiency, and facilitate maintenance with the effect of replacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

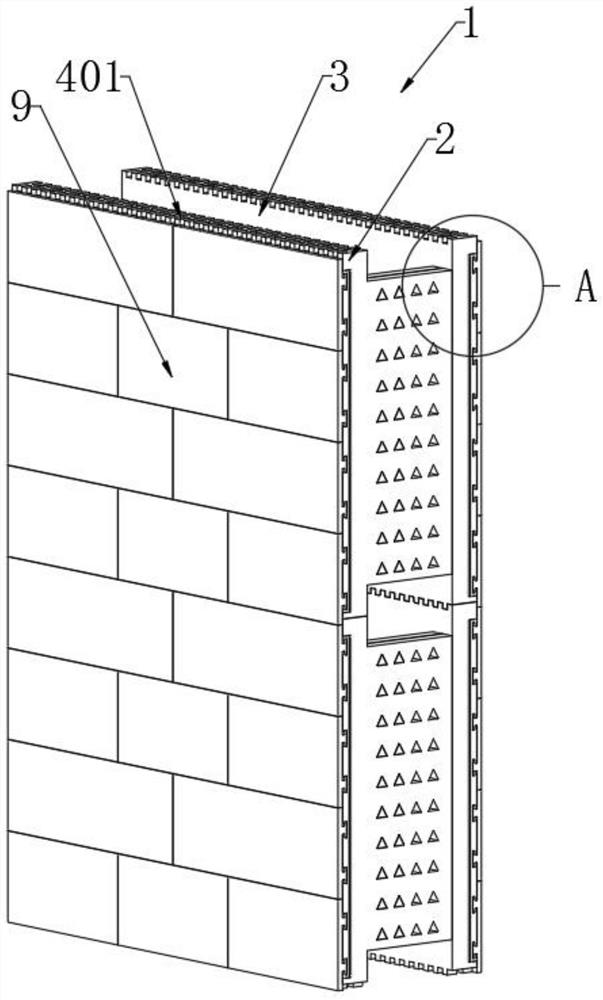

[0050]As attachedfigure 1 AttachedPicture 11 Shown:

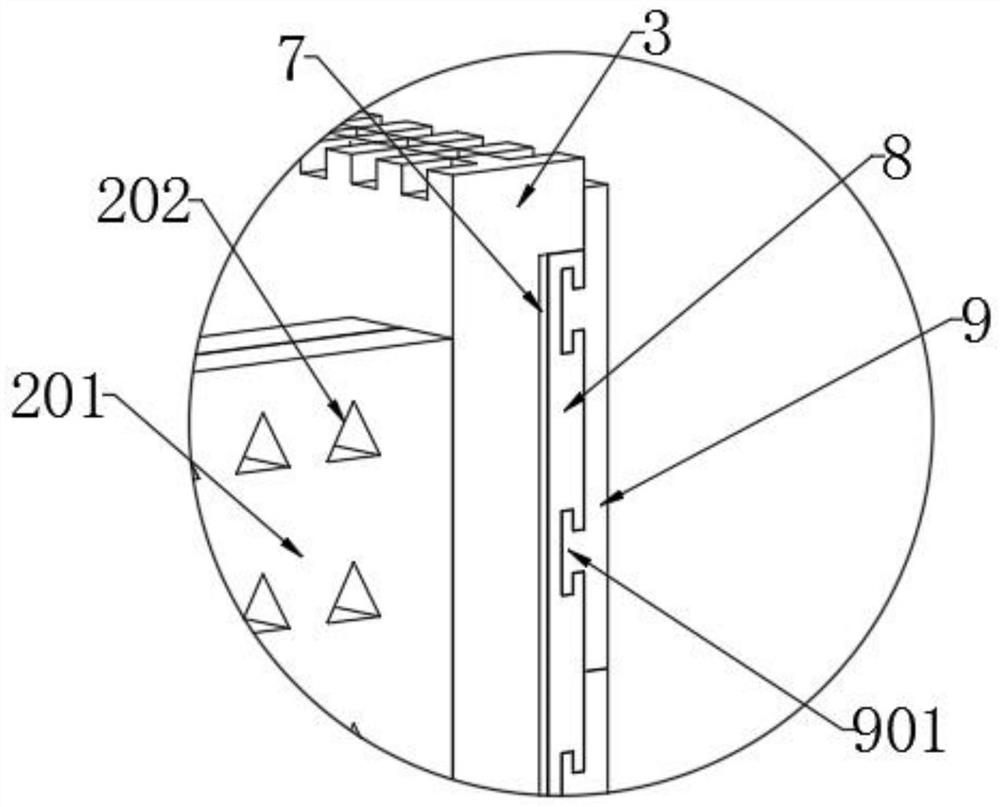

[0051]The present invention provides a fabricated building composite exterior wall panel structure, which includes a wall panel body 1, an assembly board A2, a connecting clip A201, a triangular card hole 202, an assembly board B3, a connecting card B301, a triangular clip 302, and upper The clamping structure 401, the lower clamping structure 402, the outer assembly groove 5, the reinforcing steel frame insertion frame 6, the adhesive layer 7, the plastic plate 8, the T-shaped card slot 801, the outer trim 9 and the T-shaped card strip 901;Figure 4 versusFigure 5 As shown, the wall panel body 1 is formed by clamping the assembly board A2 and the assembly board B3, and the upper and lower ends of the assembly board A2 and the assembly board B3 are respectively provided with an upper clamping structure 401 and a lower clamping structure 402. ,Such asFigure 7 As shown, the inner two ends of the assembling board A2 are respectively con...

Embodiment 2

[0059]Such asFigure 12 to Figure 20 Shown:

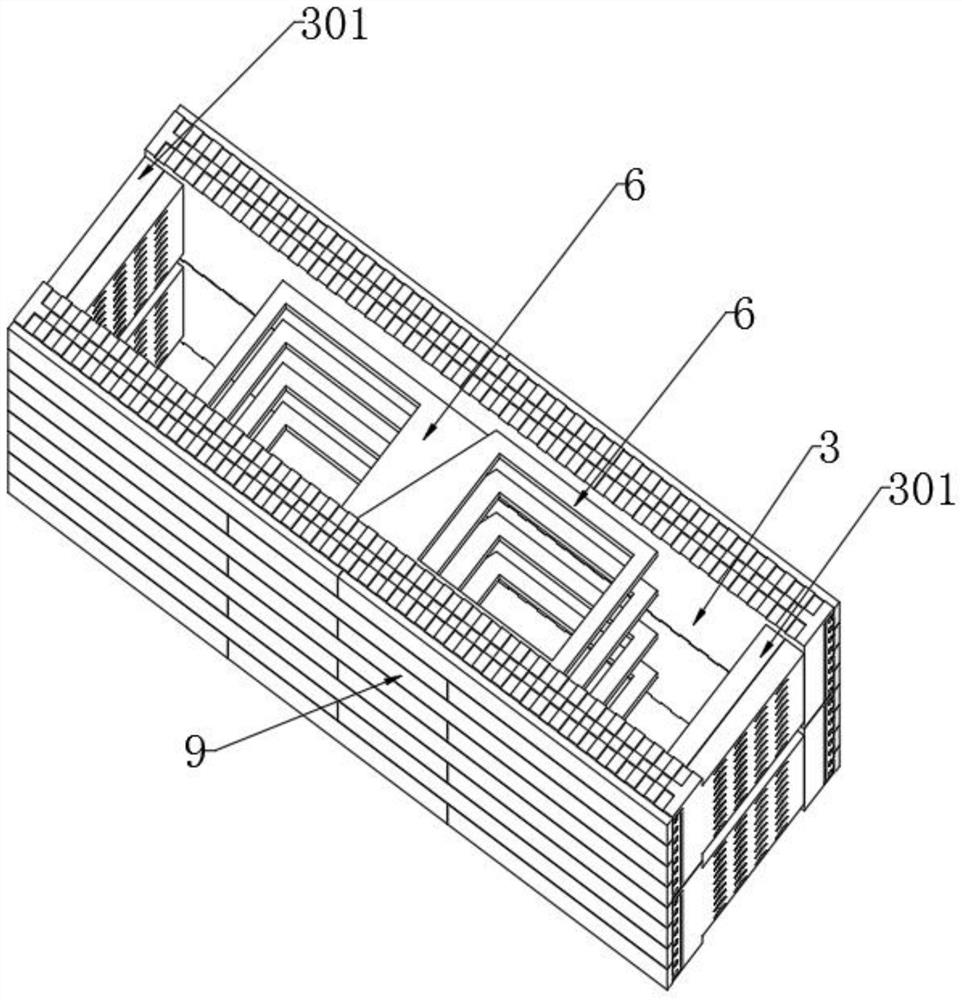

[0060]Wherein: the reinforcing steel frame inserting frame 6 is made of transparent plastic board material, and it is a trapezoidal side frame with rectangular jacks inside, and the building-filled reinforcing steel cage frame G is evenly distributed in four places, so the four inner rectangular jacks The corners penetrate the building foundation downward, and the existing steel cage G is welded by steel bars, that is to say, four steel cage G in the steel frame insertion frame 6 must be inserted downwards.

[0061]Wherein: the reinforcing steel frame interspersed frame 6 is not only a trapezoidal side frame structure that is not easily deformed, but also a trapezoidal hollow cavity structure on the bottom surface, and a ring of reinforcing plate 601 structure is also provided in the trapezoidal hollow cavity on the bottom surface, which improves its transparency. At the same time, the cavity rib structure is used to make it more difficult to d...

Embodiment 1

[0069]After the above-mentioned panels in Example 1 are connected as required, it is necessary to inject cement or concrete into the inner cavity of the wall panel to improve the installation strength of the wall panel standing on the foundation. In actual construction, it is necessary to tie the steel bar first. The good steel bar is the steel bar cage G above. We can weld a row of welded nuts on its outer wall, and then make them go down in every four groups or pass from bottom to top in advance in each bar frame insertion frame 6. The steel bar The bottom end of cage G is inserted into the foundation to form aFigure 16 to 20What we have pointed out is: we have improved the structure of the steel frame inserted into the frame 6 to make it a side-inclined trapezoidal hollow frame structure, so it is not easy to deform, and there is a ring of reinforcement plates 601 in the cavity , It is less susceptible to deformation due to the impact of injected cement or concrete, and through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com