Rapid fish flesh separating device

A kind of separation equipment and fast technology, which is applied in the direction of processing fish, slicing fish, slaughtering, etc., can solve the problems of high time cost, unsuitable for large-scale commercial processing, etc., and achieve fast separation speed, simple structure and slow down speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

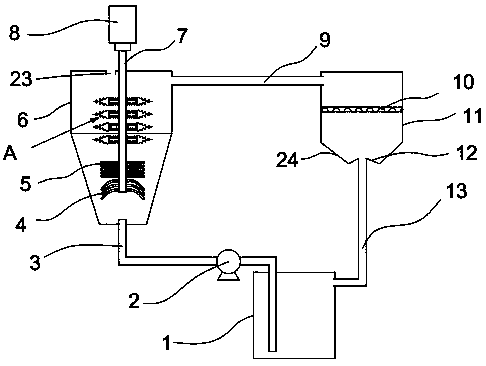

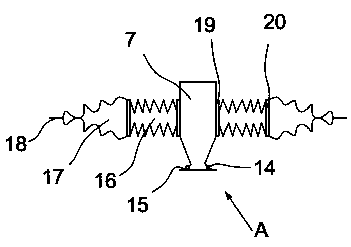

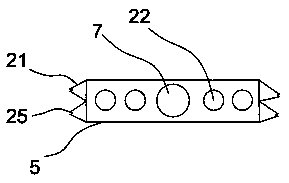

[0019] Such as Figure 1-3 Shown, a kind of quick separation equipment of fish flesh comprises a kind of quick separation equipment of fish flesh, comprises separation pool 6, and the upper end of separation pool 6 is provided with feed port 23, and the top of feed port 23 is provided with motor 8, and the output end of motor 8 is connected to rotate The shaft 7 and the rotating shaft 7 are hollow, and the rotating shaft 7 is sequentially connected with a crushing device A, a separation plate 5, and a stirring rod 4 from top to bottom. A water pump 2 is provided, located between the separation tank 6 and the liquid storage tank 1, the upper side of the separation tank 6 is connected to the upper side of the screening tank 11 through the collection pipe 9, and the lower end of the screening tank 11 is connected to the upper side of the liquid storage tank 1 through the liquid collection pipe 13 , by setting the mincing device A, separating plate, and stirring rod, the fish is m...

Embodiment 2

[0028] The present invention is a kind of quick separation device for fish meat, and its working principle is: put the cooked fish into the separation pool 6 from the feed port 23, through the grinding device A, the separation plate 5, and the stirring rod 4, the fish is sequentially processed. Grinding, separation, and stirring functions separate the fish meat from the fishbone. At the same time, turn on the water pump 2 and pump the hot water in the reservoir 1 into the separation tank 6 through the water pipe 3. After separation, the fish meat is suspended on the water surface, and the fishbone sinks into the separation tank. In the pool 6, when the hot water is continuously pumped in, the fish enters the screening pool 11 through the collection pipe 9, and under the action of the filter screen 10, the fish meat is collected on the filter screen 10, and the soup enters from the liquid collection pipe 13. The liquid storage tank 1 is recycled and recycled several times to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com