Anti-condensation lamp shade for steam cooking appliance and steam cooker

A technology for cooking utensils and anti-condensation, which is applied in the direction of steam cooking utensils, special materials for cooking utensils, cooking utensils, etc. It can solve the problems that cannot be effectively improved and affect the lighting effect of lighting lamps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

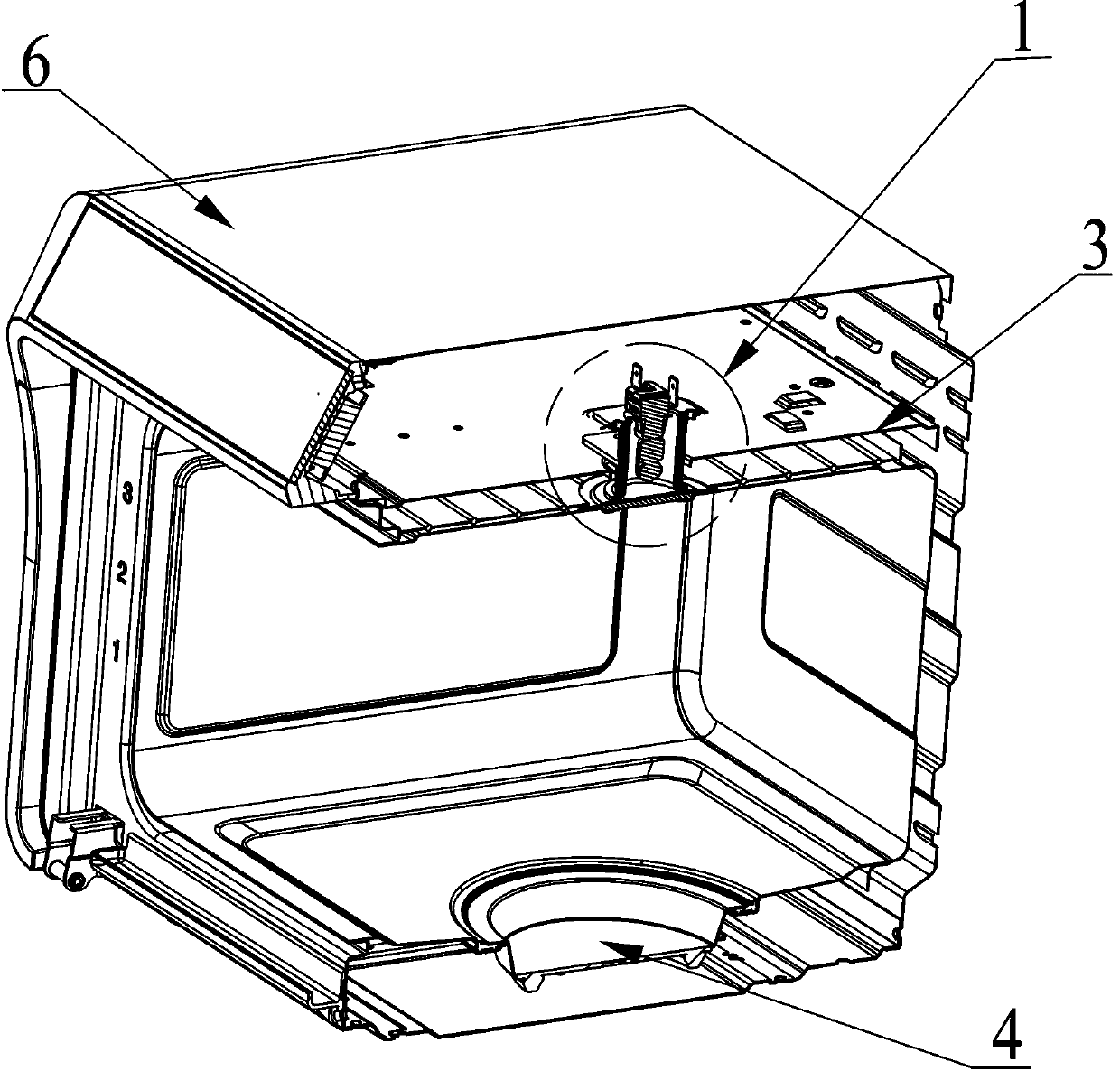

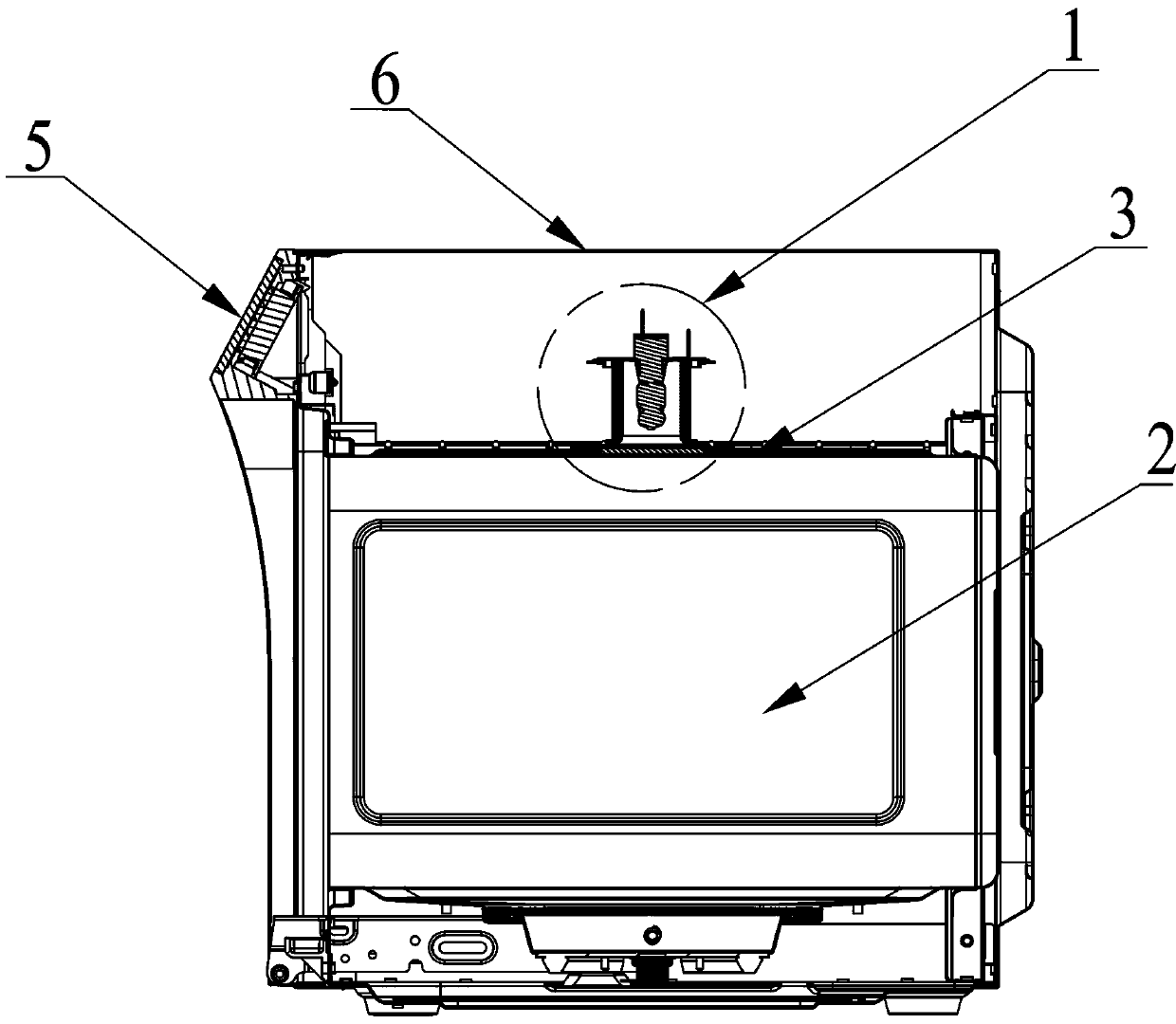

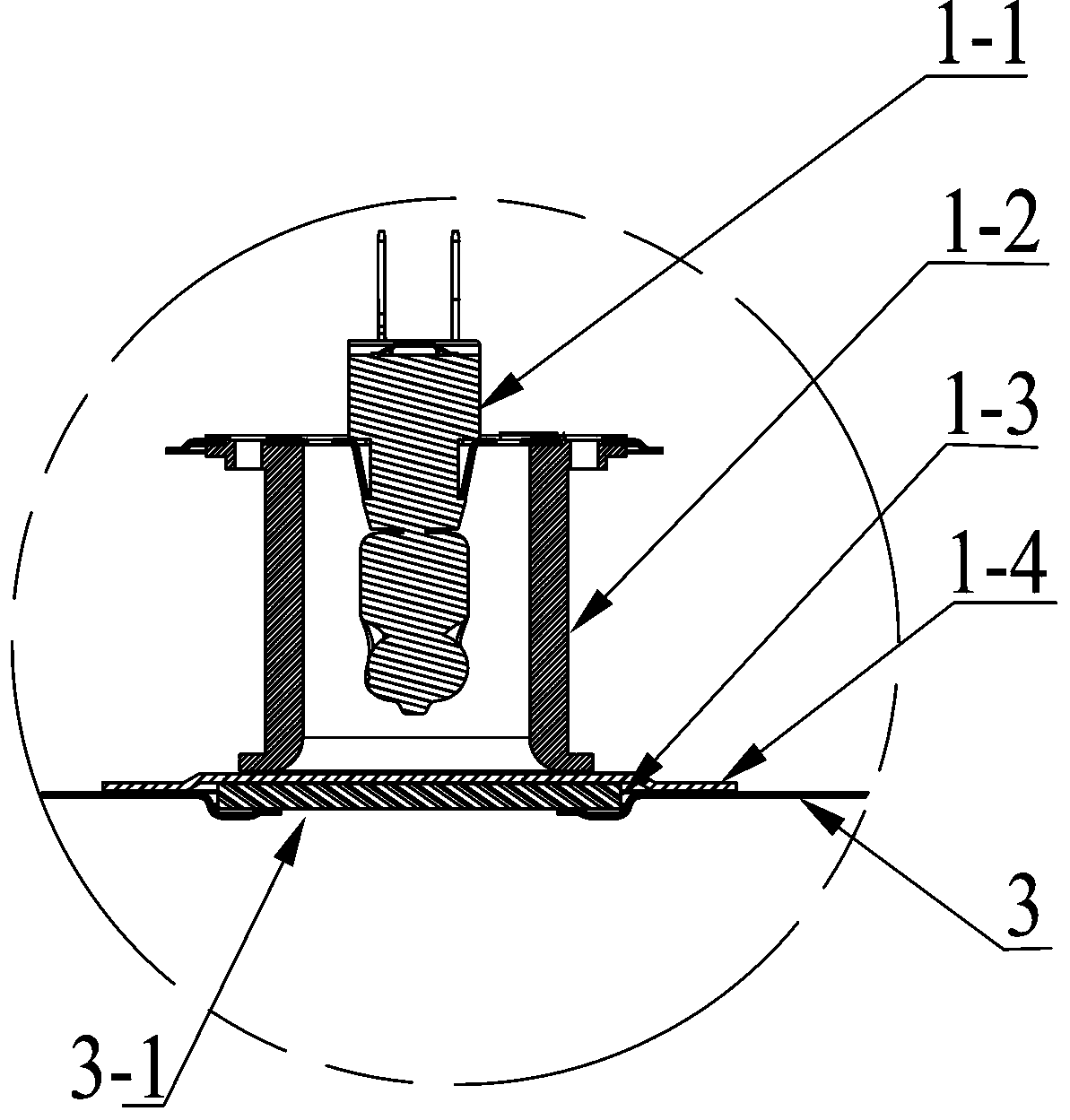

[0037] Such as Figure 1-4 As shown, it is the first embodiment of an anti-condensation lampshade for a steam cooking appliance according to the present invention. A cavity 2, a top plate 3, a steaming plate 4, a control panel 5, and a casing 6 for the food to be cooked. The top plate 3 is located above the cavity 2, and the top plate 3 has an opening 3-1. The lighting lamp assembly 1 is arranged above the top board 3. The lighting lamp assembly 1 includes a bulb 1-1, a lamp holder 1-2, a lampshade 1-3, The electric heating diaphragm 1-4, wherein the lampshade 1-3 is installed on the opening 3-1 of the top plate 3, and the lower surface of the lampshade 1-3 is attached to the upper surface of the top plate 3 at the opening 3-1.

[0038] The anti-condensation lampshade of this embodiment includes: a lampshade 1-3 and a heating layer disposed close to the inner or outer surface of the lampshade 1-3, both the lampshade and the heating layer are made of light-transmitting materia...

Embodiment approach

[0043] Such as Figure 1-2 , 5 shows the second embodiment of an anti-condensation lampshade for a steam cooking appliance according to the present invention. The cavity 2, the top plate 3, the steaming plate 4, the control panel 5 and the casing 6 are used to place the food to be cooked. The top plate 3 is located above the cavity 2, and the top plate 3 has an opening 3-1. The lighting lamp assembly 1 is arranged above the top board 3. The lighting lamp assembly 1 includes a bulb 1-1, a lamp holder 1-2, and a metal heating film. Coated lampshade 1-5, wherein, the lampshade 1-5 with metal heating film coating includes a lampshade and a heating layer arranged close to the inner or outer surface of the lampshade, and both the lampshade and the heating layer are made of light-transmitting materials of; the heating layer comprises conductive metal. The heating layer is metal heating film coating, such as Figure 5 As shown, the metal heating film coating can be applied on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com