Grinding process and grinding cylinder structure of a horizontal ball mill

A horizontal ball mill and grinding process technology, applied in grain processing, etc., can solve the problems of insufficient output and fineness of only 45 μm, and achieve the effects of improving efficiency, reducing particle size, and meeting the impact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Such as Figure 13 As shown, the present embodiment discloses a grinding process of a horizontal ball mill, comprising:

[0067] The barrel of the ball mill is divided into several sub-compartments, and there are interconnected gaps between adjacent sub-compartments; four sizes of grinding bodies are arranged in each sub-compartment;

[0068] A reinforcement plate is installed in the sub-compartment, the reinforcement plate fits the inner wall of the cylinder, and the reinforcement plate axially pulls the two side walls of the stator compartment tightly;

[0069] Input raw materials into the cylinder, rotate the cylinder for grinding, and obtain materials with d97≤10μm.

[0070] In this embodiment, the cylinder body used has a length of 16 m and an inner diameter of 2.4 m, and the length of each sub-compartment is set to be 0.5 m. The entire cylinder body can be divided into 32 sub-compartments.

[0071] It can be known that when using a horizontal ball mill for mater...

Embodiment 2

[0083] This embodiment discloses a grinding cylinder structure of a horizontal ball mill, the purpose of which is to make the particle size of the material grinded by the ball mill smaller while ensuring sufficient output.

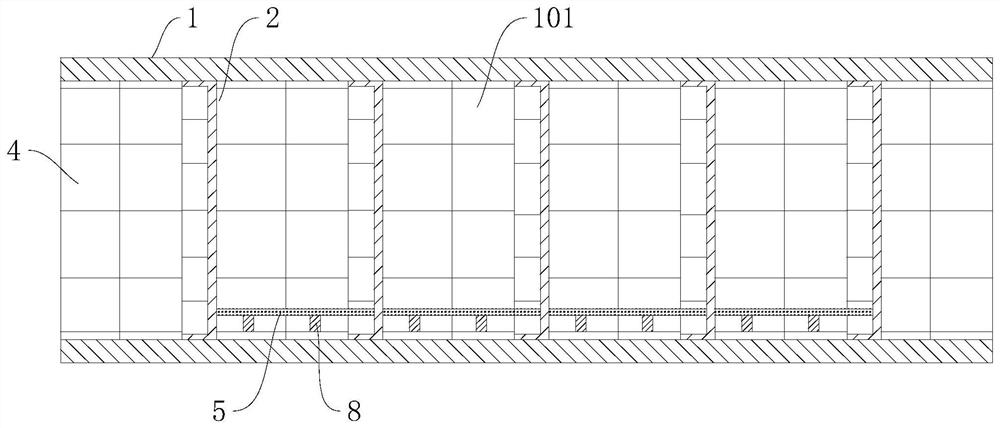

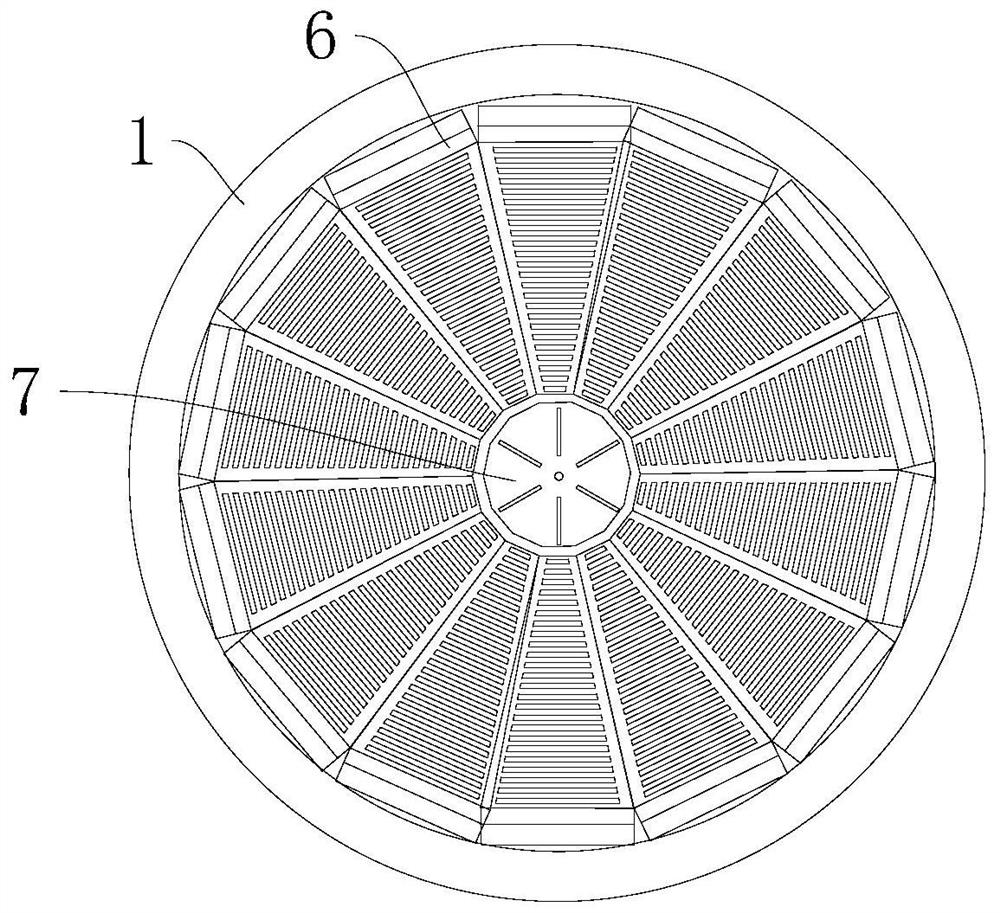

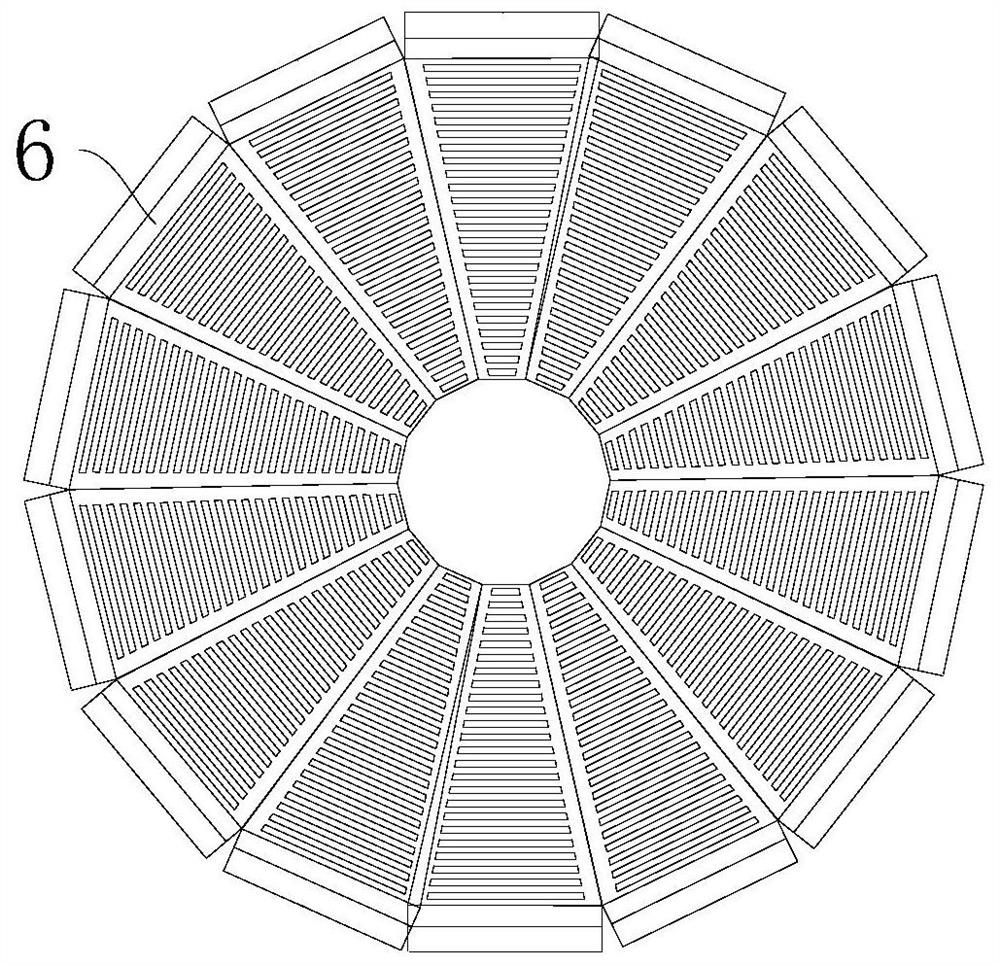

[0084] Such as Figure 1 to Figure 12 Shown is a grinding cylinder structure of a horizontal ball mill, through which the grinding cylinder structure can be used to realize the grinding process disclosed in the technical solution, specifically, the grinding cylinder structure includes a cylinder, and the cylinder is along Several partition structures 2 are arranged at intervals along the direction of the cylinder body, and several reinforcement plates 4 are provided on the inner wall surface of the cylinder body, and two adjacent partition structures 2 are connected and fixed by support members 5; The inner wall surface of the combined cylinder is surrounded by adjacent partition structures 2 to form a sub-compartment 101, and the partition structure 2 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com