A wind blade automatic flip mold clamping device

A technology of automatic flipping and mold clamping device, which is applied to household appliances, other household appliances, household components, etc. It can solve the problems of unstable movement, discontinuous flipping process, and easy to generate large impact, so as to save workshop space and load Evenly distributed, avoiding the effect of fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

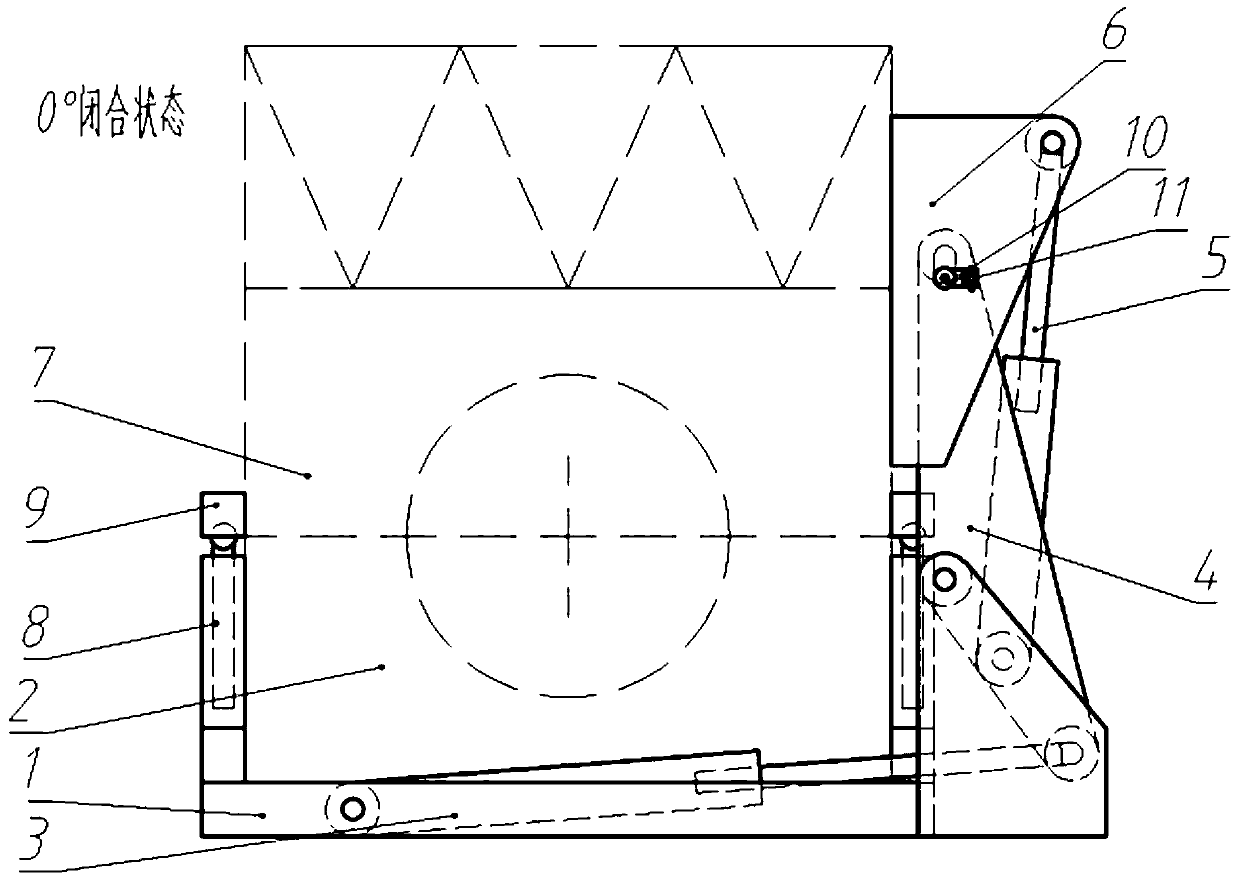

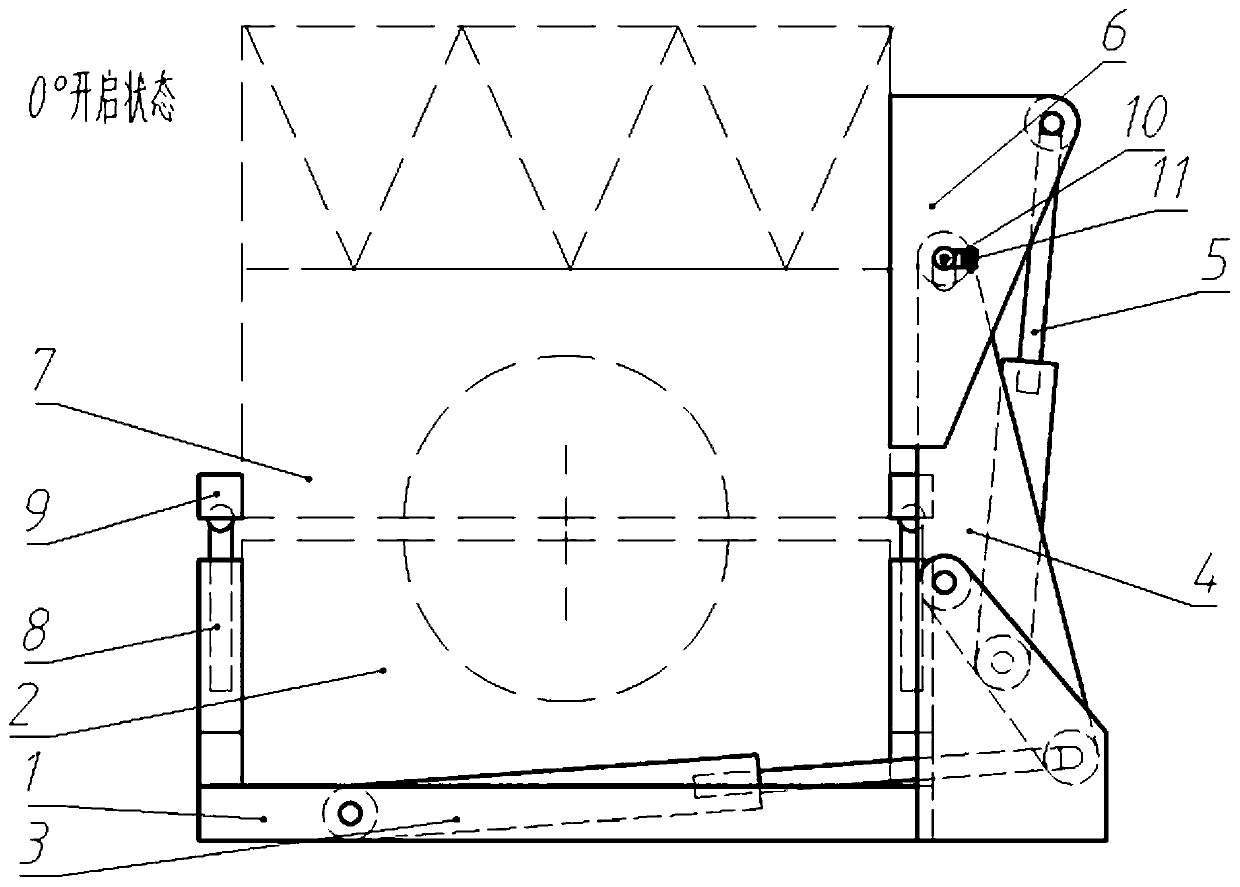

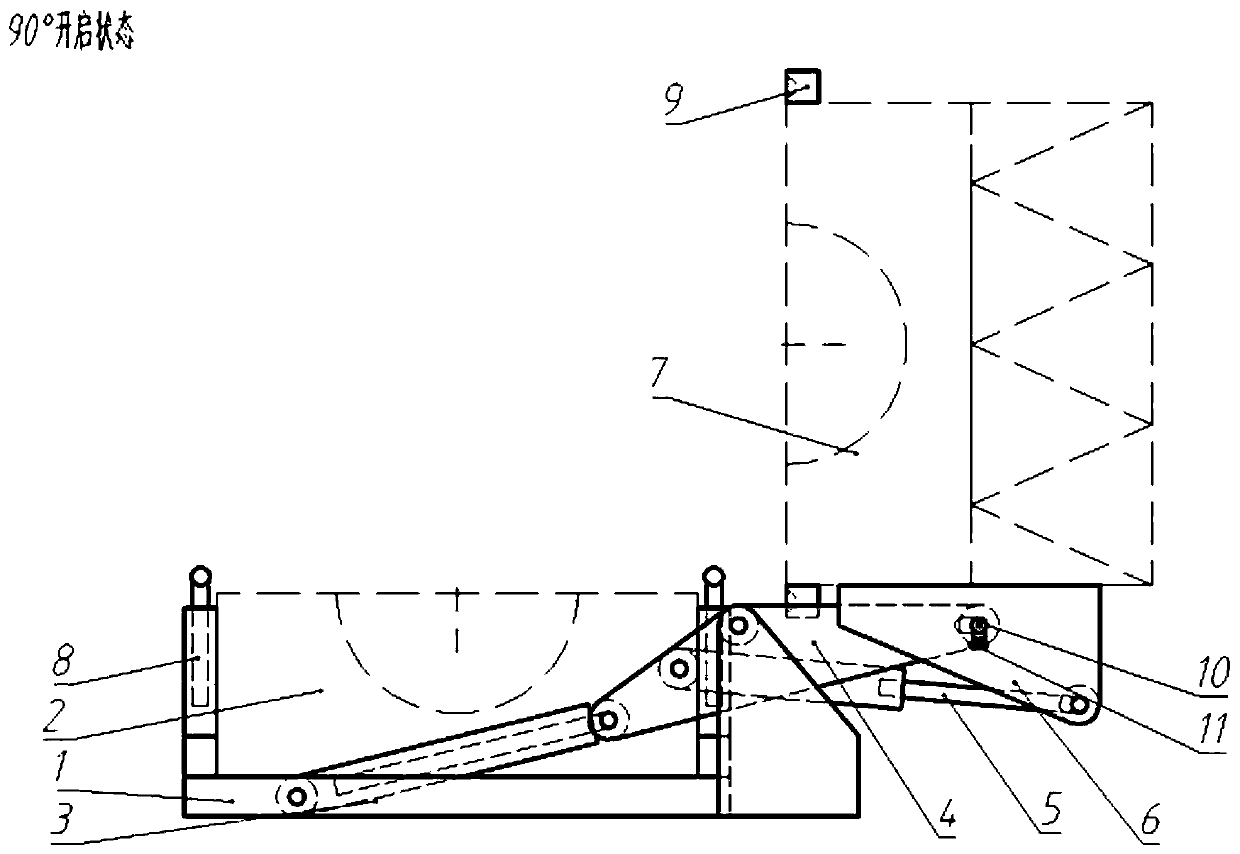

[0025] Such as Figure 1-4 , an automatic flipping mold clamping device for wind blades, used for the manufacture of wind turbine blades, the device includes a fixed lower mold 2, and a reversible upper mold 7, the upper and lower molds can be opened and closed by flipping and moving in translation. The turning mechanism is composed of main hydraulic cylinder 3, auxiliary hydraulic cylinder 5, main rocker arm 4, and auxiliary rocker arm 6. The main hydraulic cylinder 3, main rocker arm 4 and lower mold 2 are installed on the base 1, and the auxiliary hydraulic cylinder 5 is installed on the On the main rocker arm 4, the auxiliary rocker arm 6 is installed on the upper mold 7; the translation mechanism is mainly composed of a jacking hydraulic cylinder 8 and a hemispherical seat 9, the hemispherical seat 9 is installed on both sides of the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com