Method of printing a print control strip onto a sheet of printing material

A technology of printing materials and measurement and control strips, applied in printing, printing devices, etc., to achieve the effect of reducing waste and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

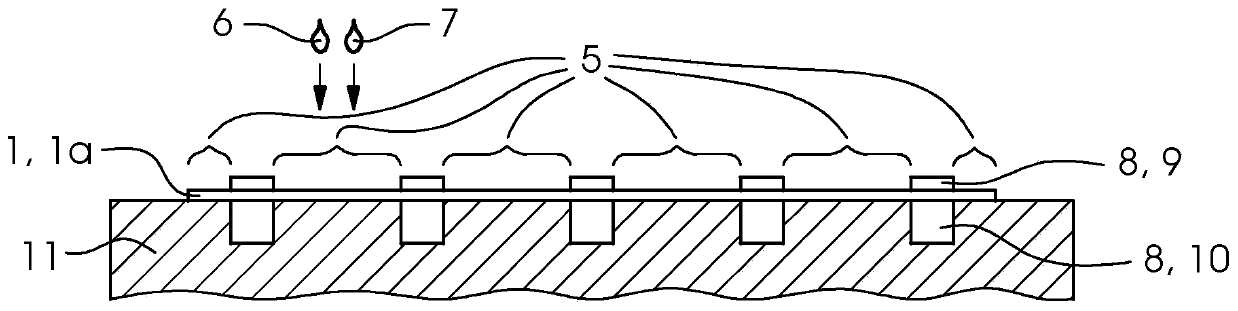

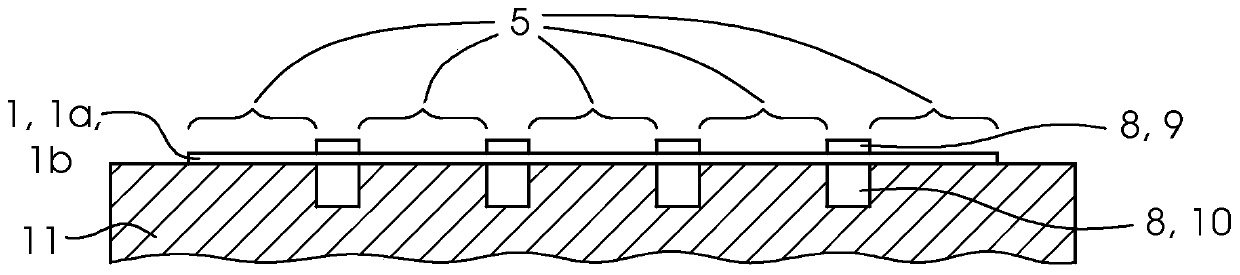

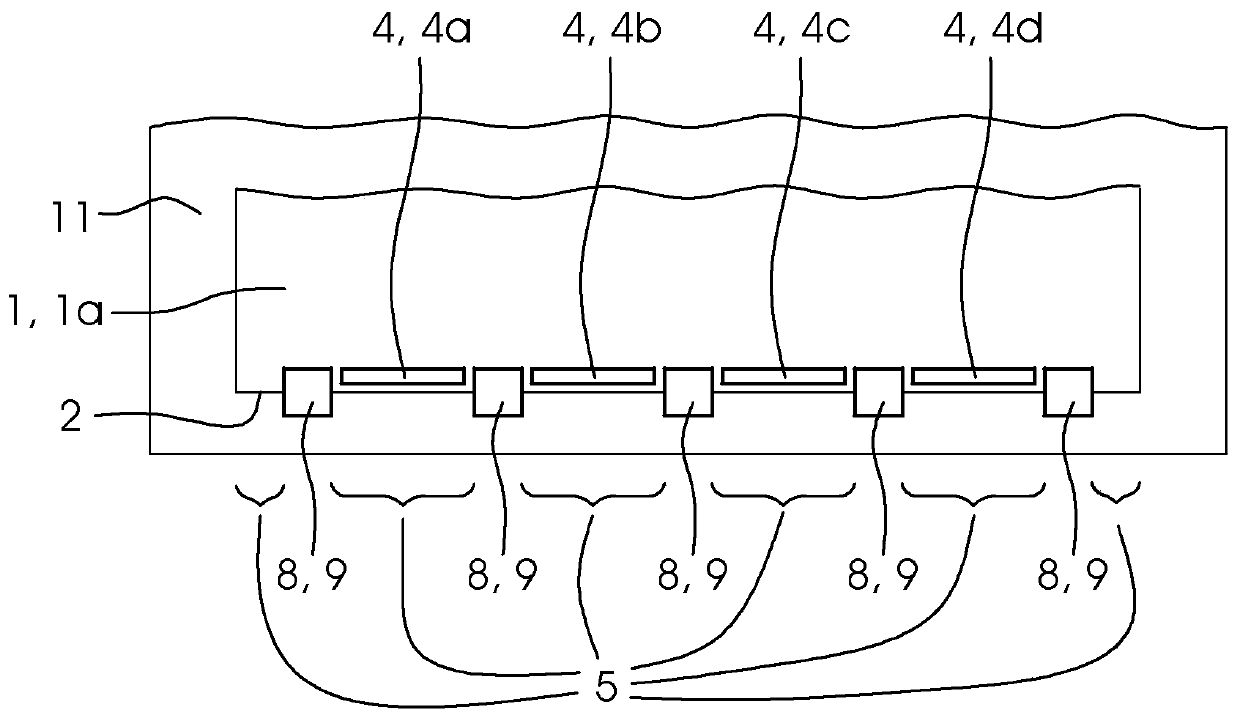

[0033] Figure 1a A device in a preferred embodiment for carrying out the method according to the invention is shown. What is shown is a front view, ie against the sheet transport direction.

[0034] The figure shows a sheet 1 (or a first sheet 1 a ) consisting of a printing material such as paper or cardboard. The front edge of the sheet is held by a plurality of grippers 8 spaced apart from each other in the transverse direction (that is, between the gripper fingers 9 and the gripper receptacles 10 of these grippers 8 ). It is clamped at edge 2 and is moved through the ink printing press in the conveying direction. These grippers are arranged on sheet transport means 11 , preferably transport rollers 11 .

[0035] In the region of the print head (not shown) of the ink printing press, the sheets are printed by ink droplets 6 according to the print image. Previously, the sheet could also be coated (for example by means of coating droplets 7 produced by an ink printing metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com