Automatic-sorting garbage cabinet and management system thereof

An automatic classification and management system technology, applied in trash cans, garbage collection, branch equipment, etc., can solve the problems of low one-time recycling capacity, high labor recycling cost, waste of materials, manpower, and land resources, and enhance awareness of environmental protection and energy conservation. , The effect of strong indoor coverage and a wide range of recycling areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

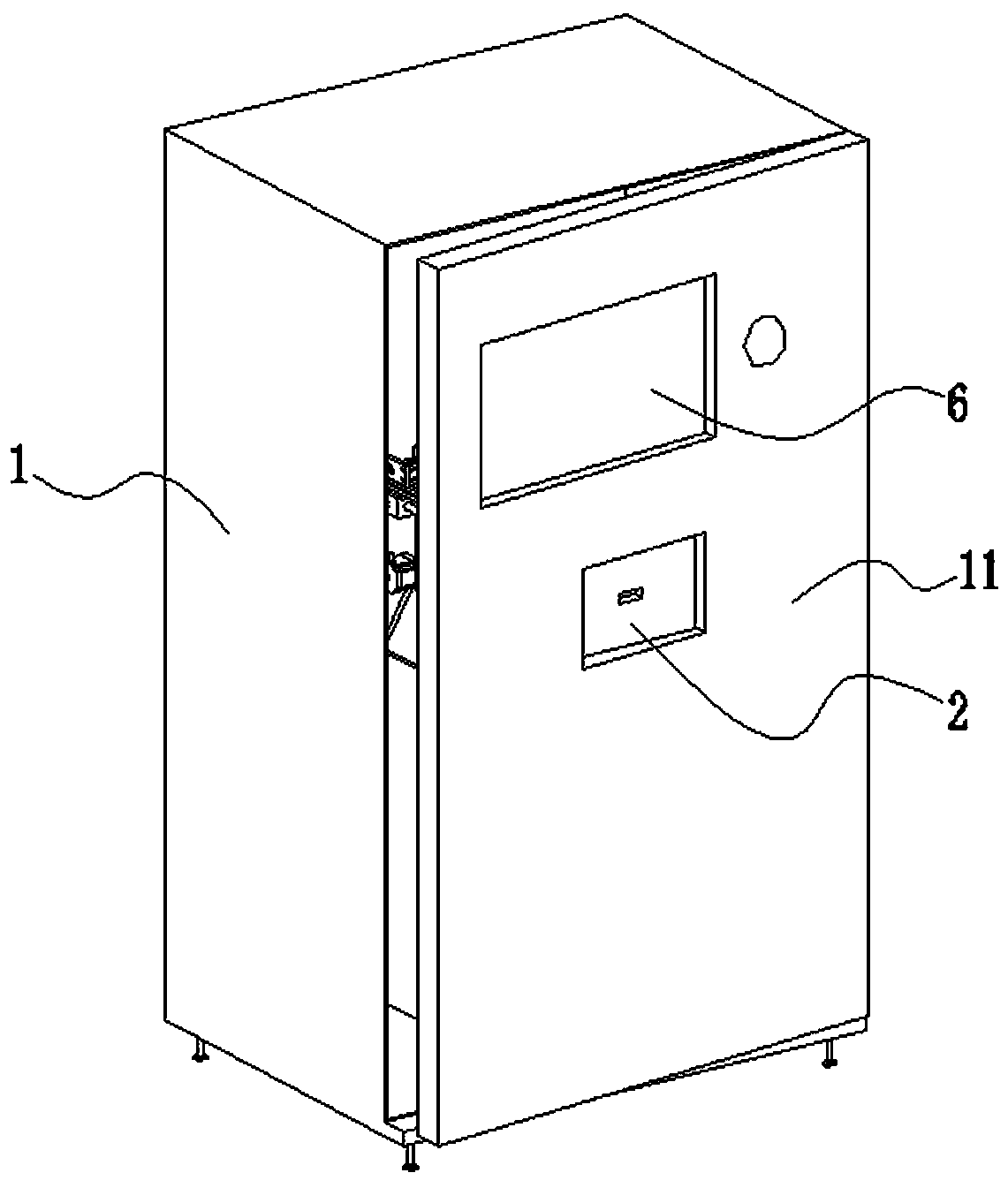

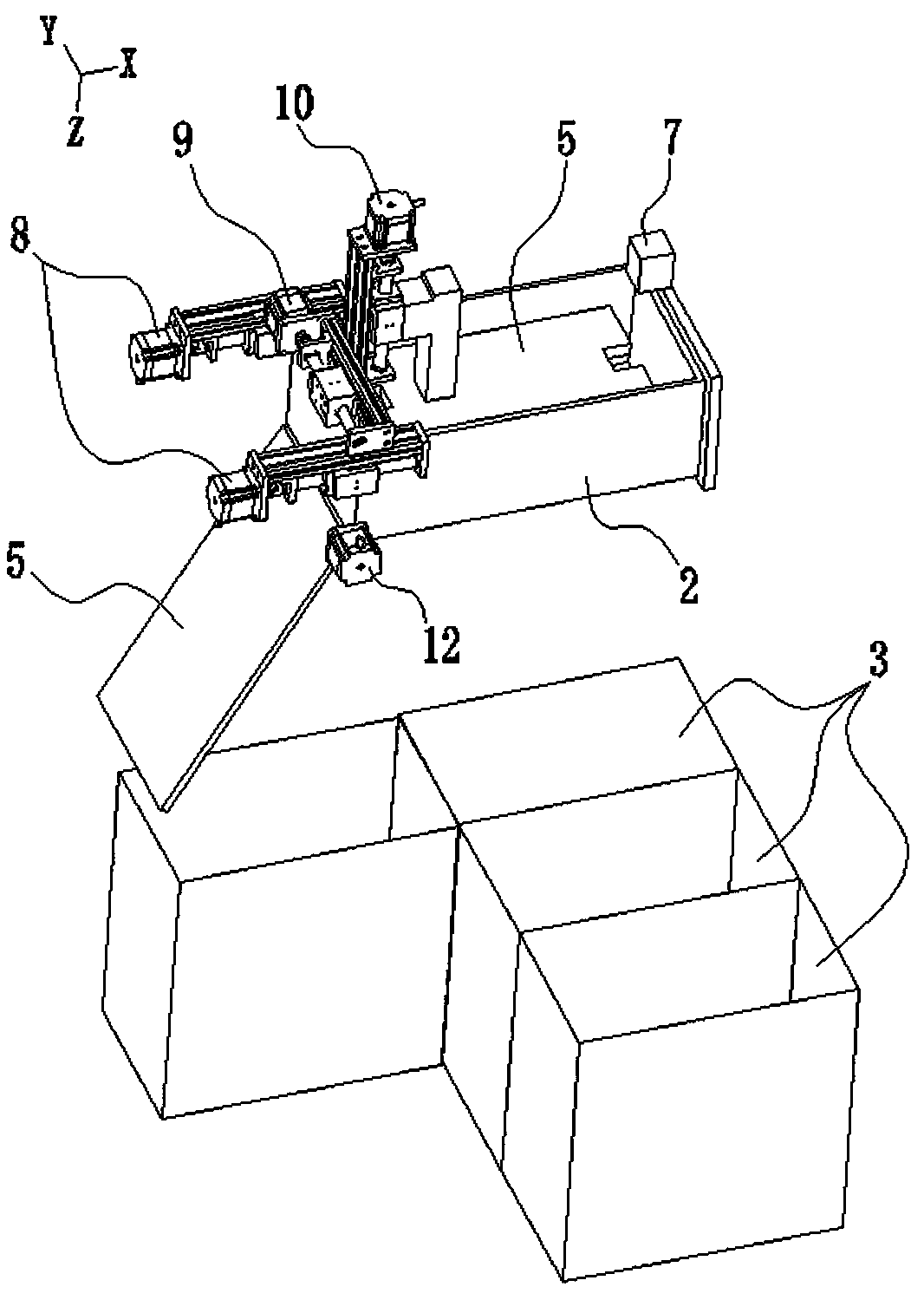

[0059] attached Figure 1-2 Example The specific embodiment of a kind of automatic sorting garbage cabinet of the present invention, refer to the attached Figure 1-2 , an automatic sorting garbage cabinet, which includes:

[0060] A cabinet body 1, the cabinet body 1 is provided with a drawer 2, the first drive device controls the drawer 2 to move outside the cabinet body 1 to open and move to the inside of the cabinet body 1 to close, the second drive device controls the drawer 2 to move to the cabinet body 1 Above the preset garbage bin 3, the third driving device controls the pressing plate 4 to descend to compress the garbage in the drawer 2 and rise to avoid the movement of the drawer 2, and the fourth driving device controls the bottom plate 5 of the drawer 2 to open to form a garbage outlet to dispose of the compressed garbage. The garbage is sent into the trash can 3 below and closed to cooperate with the pressing plate 4;

[0061] The display screen 6 is arranged o...

Embodiment 2

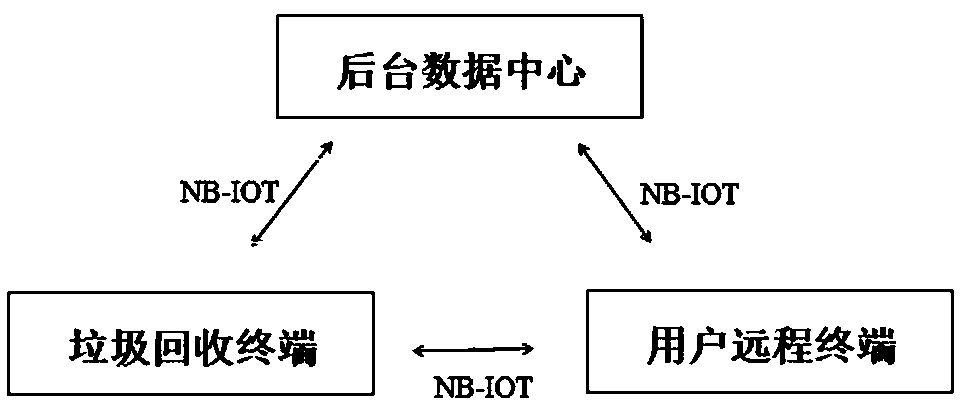

[0073] like Figure 3-4 As shown, a management system for automatically sorting garbage bins based on point rebates, which includes a background data center, a garbage recycling terminal, and a user remote terminal; the garbage recycling terminal adopts an automatic sorting garbage bin in Embodiment 1, It actually also includes a garbage weighing module, a core control module, a garbage overflow detection module, a storage module, a camera module, an advertisement and point display module, the first NB-IOT information transmission module and the first NB-IOT positioning module;

[0074] The weighing module is used to weigh the garbage placed by the user;

[0075] The core control module is responsible for controlling the operation of the entire garbage collection terminal and processing the garbage weighing module, garbage overflow detection module, storage module, camera module, advertisement and point display module, the first NB-IOT information transmission module and The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com