Anti-blocking aeration head

An aeration head and anti-blocking technology, applied in biological sludge treatment and other directions, can solve problems such as blockage of aeration discs, and achieve the effect of preventing sludge from entering the exhaust hole and blocking the aeration head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

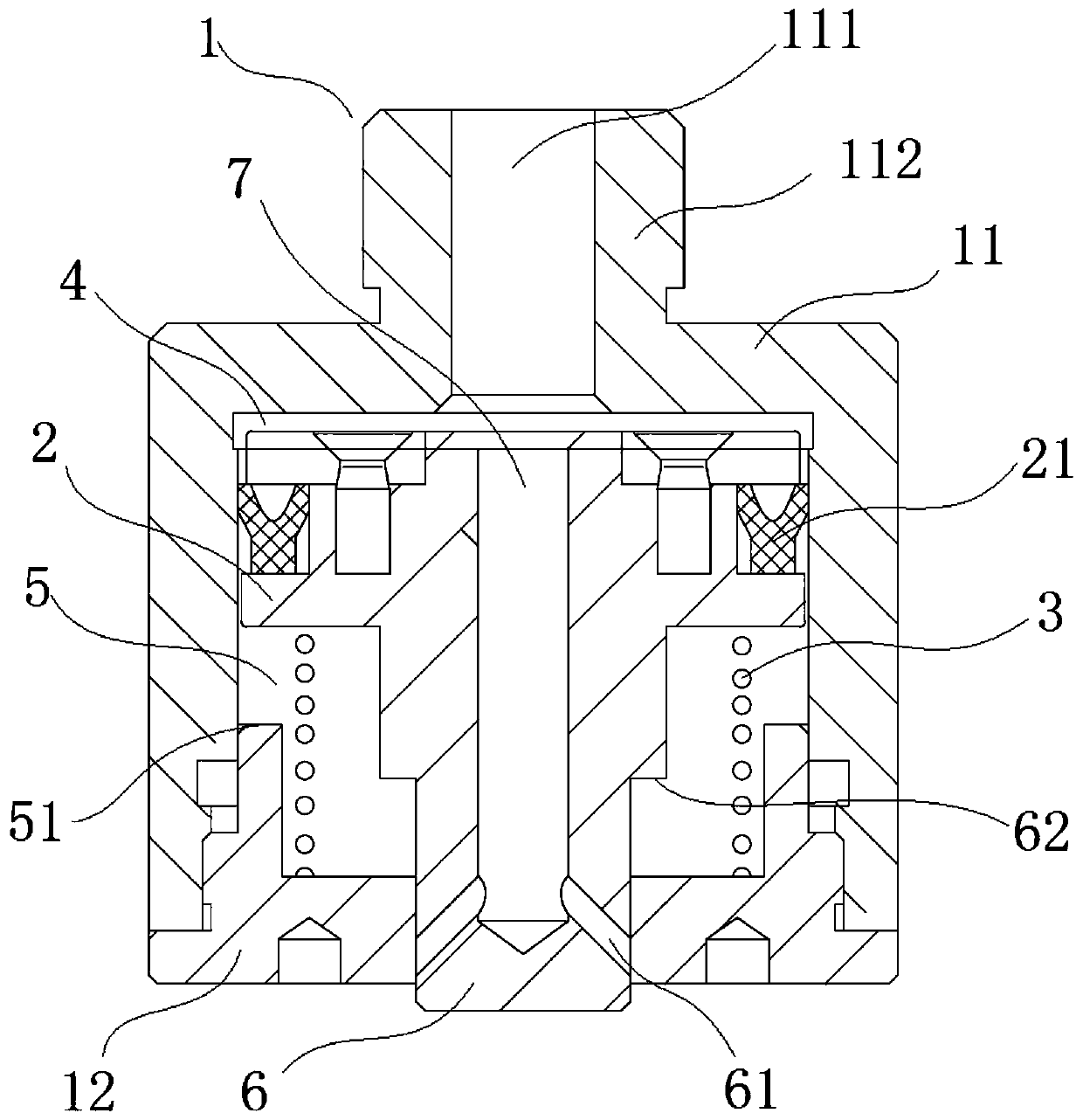

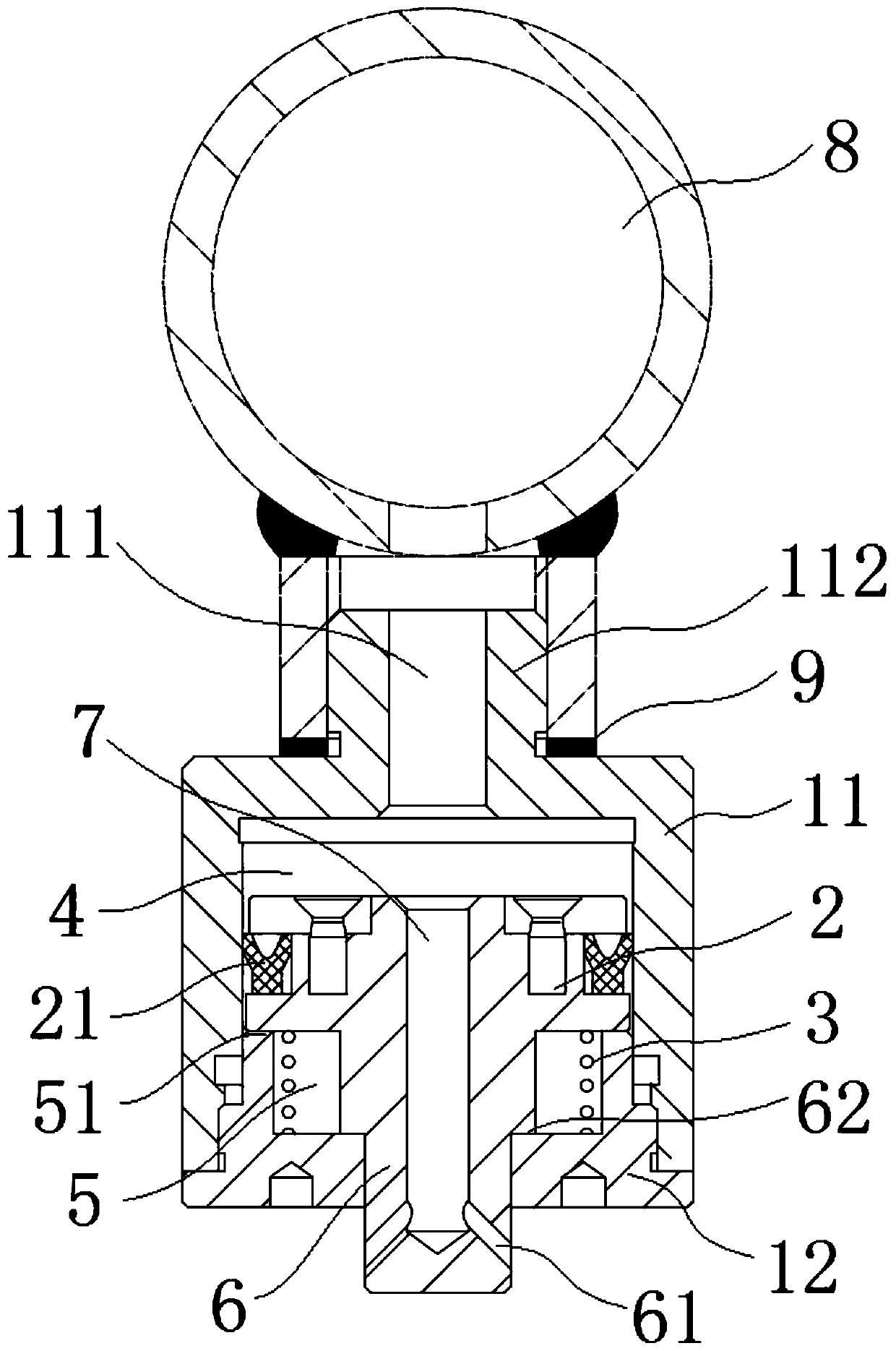

[0022] like Figures 1 to 3 As shown, an anti-blocking aeration head includes a cylinder body 1, a piston 2 and a return spring 3, the piston 2 is arranged in the cylinder body 1, and the cylinder body 1 is divided into a cavity A4 and a cavity B5, and the cavity A4 and the cavity B5 The air inlet 111 of the barrel 1 is connected, and the return spring 3 is arranged in the cavity B5; it also includes the piston rod 6 arranged in the cavity B5, and the end of the barrel 1 opposite to the air inlet 111 is provided with a piston rod for installation. 6 mounting holes, one end of the piston rod 6 is connected to the piston 2, and the other end is penetrated in the mounting hole; a blind hole channel 7 is provided from one end of the piston 2 to the other end of the piston rod 6, and the opening end of the blind hole channel 7 Located at one end of the cavity A4 , the piston rod 6 is provided with an exhaust hole 61 communicating with the blind hole channel 7 , and the exhaust hole...

Embodiment 2

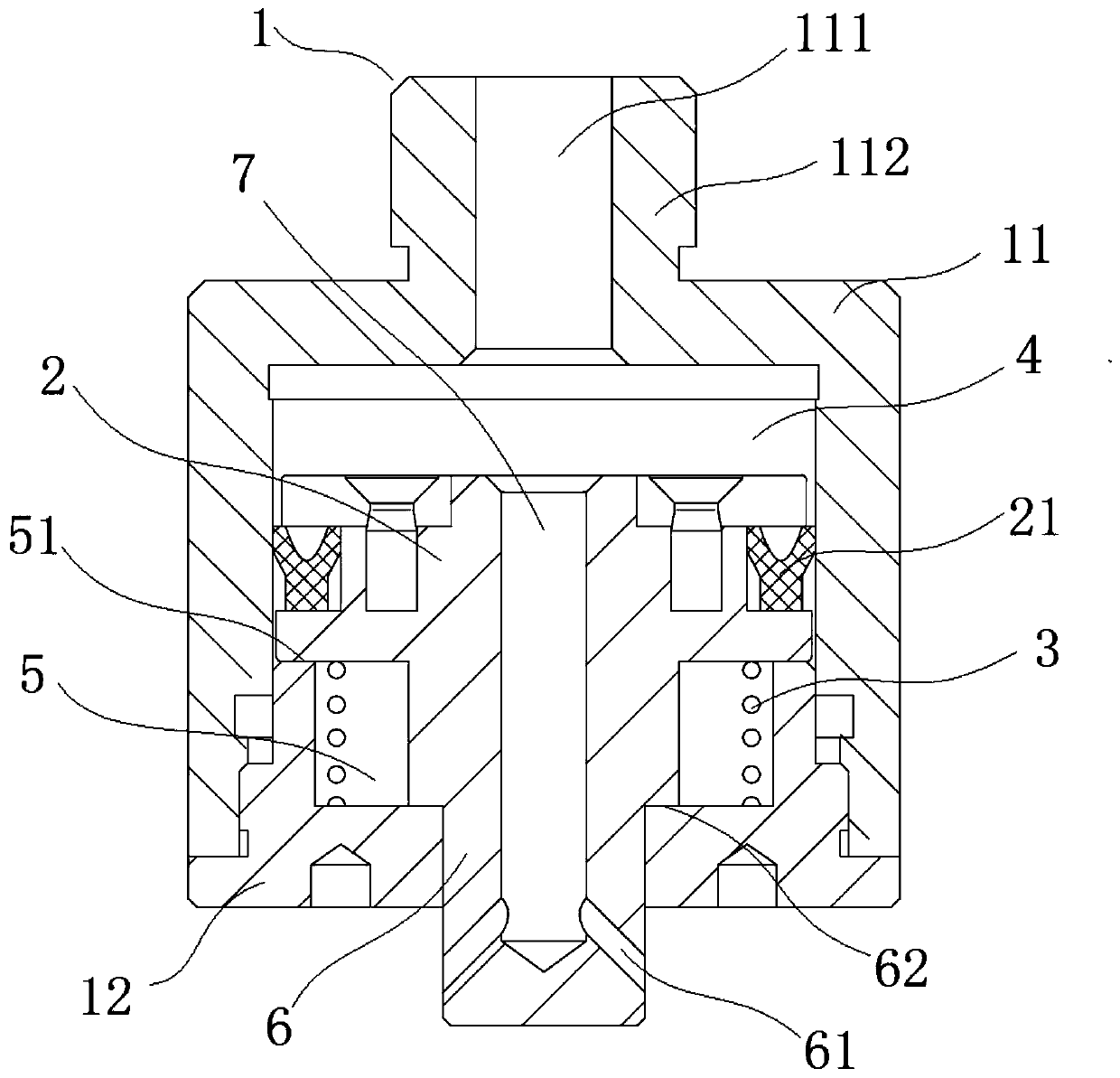

[0030] This embodiment is similar in structure to other parts of Embodiment 1, the difference is that the exhaust hole 61 is arranged obliquely, and the gas outlet end of the exhaust hole 61 is inclined towards the end away from the piston 2 . As preferably, a plurality of exhaust holes 61 are provided, and a plurality of exhaust holes 61 are arranged obliquely, that is, they are inclined toward the direction in which the piston rod 6 extends into the mud, so that the mud can be further prevented from entering the exhaust holes 61 to the blind holes. In the channel 7; when the piston rod 6 moves back to the installation hole, even if there is mud outside the vent hole 61, on the one hand, the vent hole 61 is inclined downward, and there is a surplus of compressed air at the same time, and the mud cannot enter the exhaust port. On the other hand, the silt on the outer wall of the piston rod 6 will also be scraped off by the mounting hole; through the above two obstacles, the sil...

Embodiment 3

[0032] This embodiment is similar in structure to other parts of Embodiment 2. The different cylinder body 1 includes a cylinder body 11 and an end cover 12, and the end cover 12 is connected to the cylinder body 11 through a threaded seal; the air inlet 111 is arranged on the cylinder body 11, and Holes are provided on the end cover 12 . Cylinder 1 includes cylinder body 11 and end cover 12, which is convenient for disassembly, installation and maintenance. When piston 2 or Y-shaped sealing ring 21 is damaged, open end cover 12, and piston 2 can be taken out for replacement or maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com