Autoclaved aerated concrete brick manufactured from urban industrial solid waste and manufacturing method thereof

An industrial solid waste, autoclaved gas filling technology, applied in the field of waste recycling and reuse, can solve problems such as difficult processing, complex components, environmental impact, etc., and achieve the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

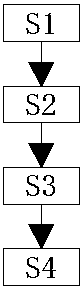

Image

Examples

Embodiment 1

[0015] Embodiment 1: A method of making autoclaved aerated concrete bricks using urban industrial solid waste, including the following components: activated carbon, blast furnace slag, steel slag, red mud, fly ash, cinder, waste gypsum, desulfurized ash, carbide slag , salt mud, cementitious material, sand, stone and additives, the mass ratio of each component is: activated carbon 20.0 parts, blast furnace slag 120.0 parts, steel slag 40.0 parts, red mud 60.0 parts, fly ash 200.0 parts, cinder 120.0 parts, waste gypsum 80.0 parts, 50.0 parts of desulfurization ash, 90.0 parts of calcium carbide slag, 70.0 parts of salt mud, 800.0 parts of cementitious material, 600.0 parts of sand, 200.0 parts of stone and 120.0 parts of additives. The mass ratio of each component is 40.0 parts of gas generating agent, 40.0 parts of regulator and 40.0 parts of bubble stabilizer.

[0016] A method for manufacturing autoclaved aerated concrete bricks by using urban industrial solid waste, compri...

Embodiment 2

[0021] Embodiment 2: A kind of autoclaved aerated concrete bricklaying made of urban industrial solid waste, including the following components: activated carbon, blast furnace slag, steel slag, red mud, fly ash, cinder, waste gypsum, desulfurization ash, carbide slag , salt mud, cementitious material, sand, stone and additives, the mass ratio of each component is: activated carbon 30.0 parts, blast furnace slag 180.0 parts, steel slag 60.0 parts, red mud 90.0 parts, fly ash 300.0 parts, cinder 180.0 parts, waste gypsum 120.0 parts, 75.0 parts of desulfurization ash, 135.0 parts of calcium carbide slag, 105.0 parts of salt mud, 1200.0 parts of cementitious material, 900.0 parts of sand, 300.0 parts of stone and 180.0 parts of additives. The mass ratio of each component is 60.0 parts of gas generating agent, 60.0 parts of regulator and 60.0 parts of bubble stabilizer.

[0022] A method for manufacturing autoclaved aerated concrete bricks by using urban industrial solid waste, c...

Embodiment 3

[0027] Embodiment 3: A kind of autoclaved aerated concrete bricklaying made of urban industrial solid waste, including the following components: activated carbon, blast furnace slag, steel slag, red mud, fly ash, cinder, waste gypsum, desulfurization ash, carbide slag , salt mud, cementitious material, sand, stone and additives, the mass ratio of each component is: activated carbon 40.0 parts, blast furnace slag 240.0 parts, steel slag 80.0 parts, red mud 120.0 parts, fly ash 400.0 parts, cinder 240.0 parts, waste gypsum 160.0 parts, 100.0 parts of desulfurization ash, 160.0 parts of calcium carbide slag, 135.0 parts of salt mud, 1600.0 parts of cementitious material, 1200.0 parts of sand, 400.0 parts of stone and 240.0 parts of additives. The mass ratio of each component is 80.0 parts of gas generating agent, 80.0 parts of regulator and 80.0 parts of bubble stabilizer.

[0028] A method for manufacturing autoclaved aerated concrete bricks by using urban industrial solid waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com