A kind of red fluorescent powder for near ultraviolet light excitation and preparation method thereof

A technology of red phosphor and near-ultraviolet light, which is applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc., and can solve undiscovered problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

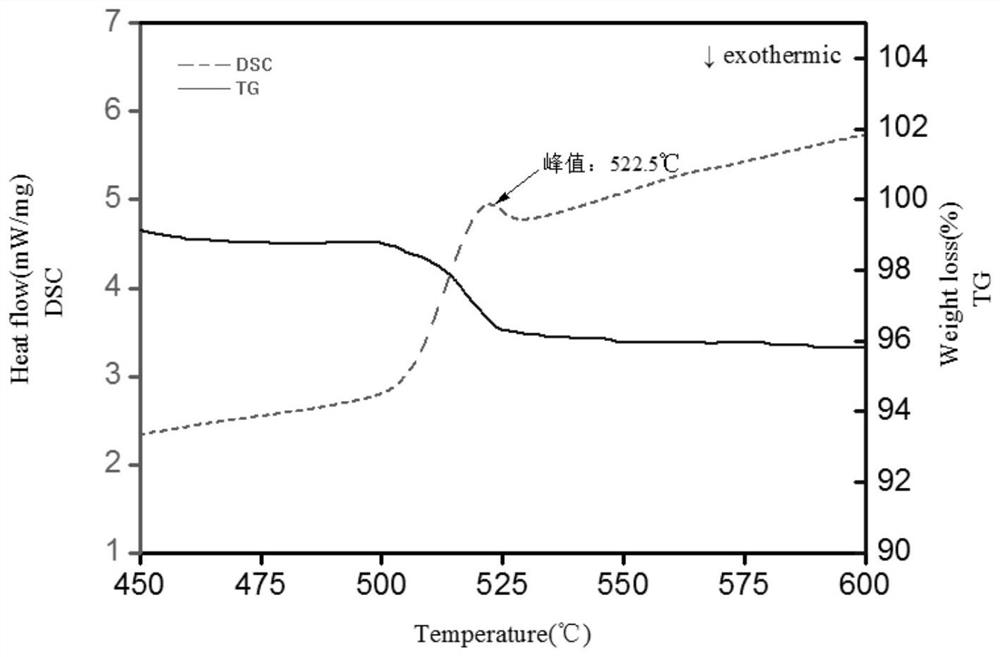

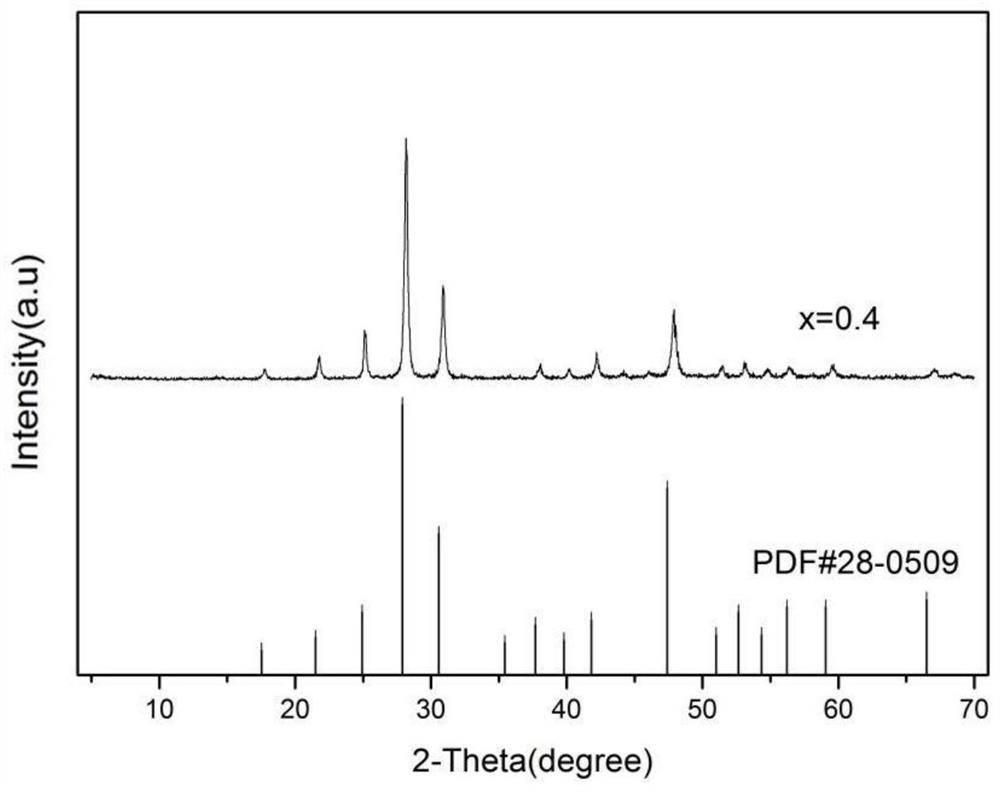

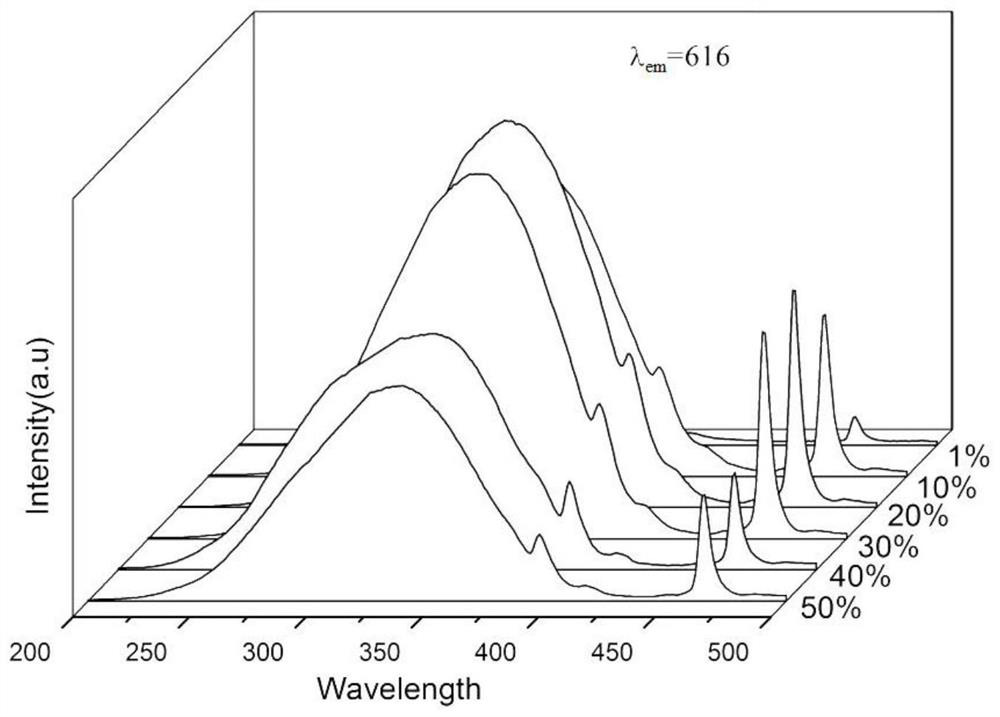

Method used

Image

Examples

Embodiment 1

[0029] Step 1, weigh 3.20mmol of La (No 3 ) 3 ·nH 2 O was dissolved in 25 mL of deionized water to form A solution, 6.40 mmol of Li2 MoO 4 Dissolve in 20mL deionized water to form solution B; stir with a magnetic stirrer for 30min;

[0030] Step 2, use a dropper to add solution A to solution B drop by drop to ensure that the solution is fully mixed, and solution B is constantly stirring during the dropwise addition, and finally a mixed solution C is formed;

[0031] Step 3: Stir the C solution for 30 minutes, adjust the pH to 9.0 with 0.1mol / L lithium hydroxide solution and 5% dilute nitric acid solution to form solution H;

[0032] Step 4, move the H solution into the p-polyphenyl liner with a filling degree of 65%, react in a stainless steel reactor at 240°C for 24 hours, and form a white precipitate;

[0033] Step 5, washing the white precipitate obtained in step 4 with deionized water and ethanol for 2 to 3 times, and centrifuging with a centrifuge at 10000r / min for 3m...

Embodiment 2

[0039] (1) Weigh 3.04mmol of La(No 3 ) 3 ·nH 2 O was dissolved in 25 mL of deionized water to form A solution, 6.40 mmol of Li 2 MoO 4 Dissolve in 20mL deionized water to form solution B; stir with a magnetic stirrer for 30min, then measure 1.6mL of Eu(NO 3 ) 3 solution;

[0040] (2) First add solution A to solution B dropwise using a dropper, during which solution B is constantly stirring to form solution C, and then add Eu(NO 3 ) 3 The solution is added to the mixed solution C drop by drop using a dropper to form a D solution;

[0041] (3) Stir the D solution for 30 minutes, adjust the pH to 9.00 with 0.1mol / L lithium hydroxide solution and 5% dilute nitric acid solution to form the precursor solution E;

[0042] (4) Move the E solution into the p-polystyrene liner with a filling degree of 67%, react in a stainless steel reactor at 240°C for 24 hours, and form a white precipitate F;

[0043] (5) Rinse the precipitate F with deionized water and ethanol for 2 to 3 tim...

Embodiment 3

[0048] (1) Weigh 2.86mmol of La(No 3 ) 3 ·nH 2 O was dissolved in 25 mL of deionized water to form A solution, 6.42 mmol of Li 2 MoO 4 Dissolve in 20mL deionized water to form solution B; stir with a magnetic stirrer for 30min, then measure 3.5mL of Eu(NO 3 ) 3 solution;

[0049] (2) First add solution A to solution B dropwise using a dropper, during which solution B is constantly stirring to form solution C, and then add Eu(NO 3 ) 3 The solution is added to the mixed solution C drop by drop using a dropper to form a D solution;

[0050] (3) Stir the solution D for 35 minutes, adjust the pH to 9.13 with a 0.15 mol / L lithium hydroxide solution and a 5% dilute nitric acid solution to form a precursor solution E;

[0051] (4) Move the precursor solution E into the p-polyphenyl liner with a filling degree of 70%, react in a stainless steel reactor at 240°C for 24 hours, and form a white precipitate F;

[0052] (5) Rinse the precipitate F with deionized water and ethanol f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com