Production method of high-elasticity fiber

A production method and high elasticity technology, applied in fiber processing, melt spinning, conjugated synthetic polymer artificial filament, etc., can solve the problems of serious product homogeneity and isomorphism, lack of core competitiveness, etc., and achieve dye uptake High, low dyeing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

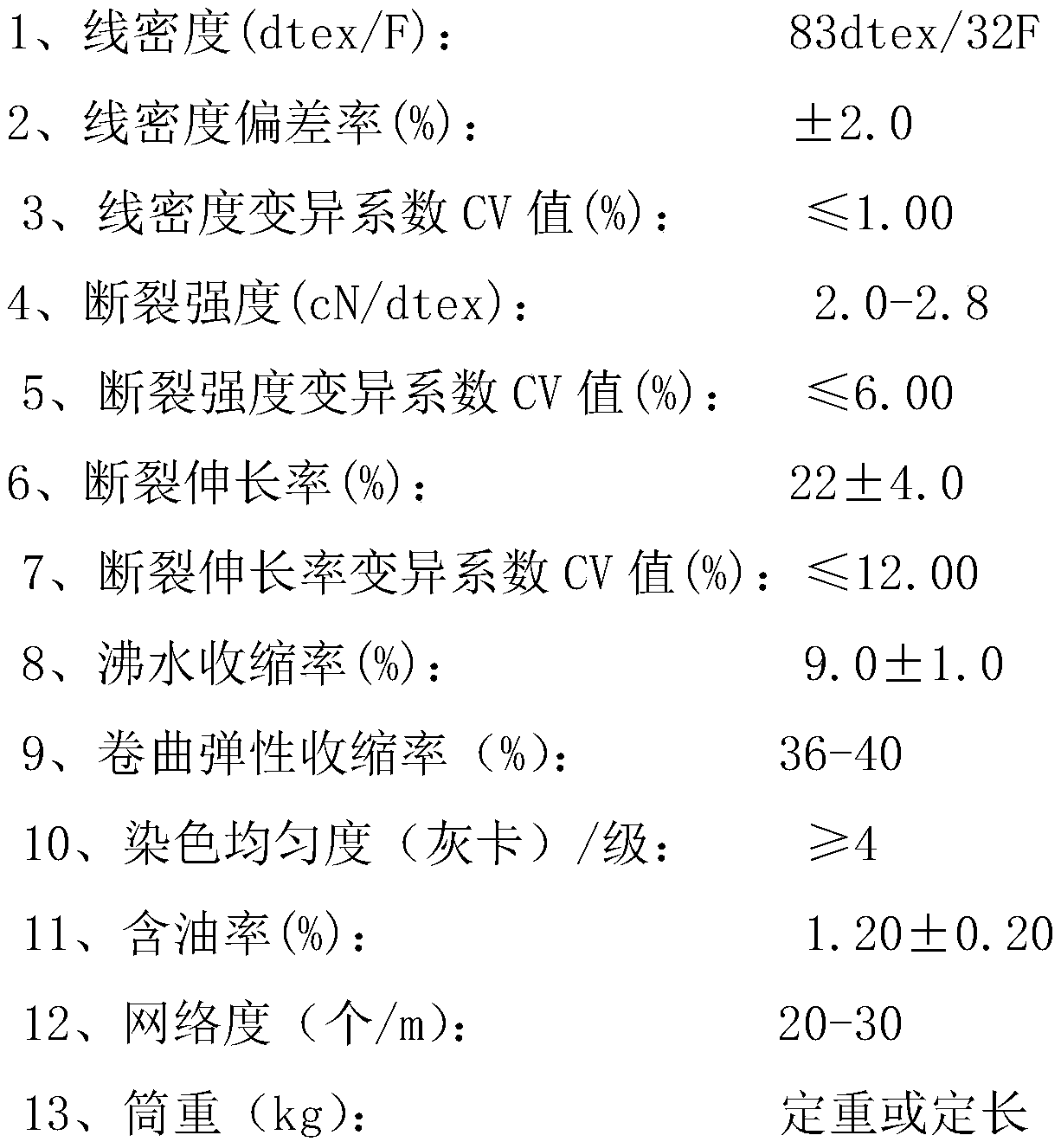

Examples

Embodiment Construction

[0018] The present invention will be further described below with regard to specific embodiment:

[0019] A production method of high elastic fiber, select PET and PBT to be transported to the spinning assembly through the twin-screw conveyor and mixed, then through side blowing, oiling, pre-network, drafting and setting, main network, winding forming, inspection, grading The packaging process is completed, in which PET enters the spinning assembly through conveying, pre-crystallization, drying, melt extrusion, filtration and box metering pump, and PBT enters the spinning assembly through conveying, drying, melt extrusion, filtration and box metering pump components. And the polyester chips used for the PBT component are specific chips with a viscosity of about 1.3dl / g from Jiangsu Hengli Group. Increase the viscosity difference between the two components; the ratio of PBT and PET components is 50:50; during the spinning process, try to reduce the PBT spinning temperature (no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com