Rotation speed regulating method for CD machine to prevent CD from producing vibration

An adjustment method and technology of optical disc drive, applied in the direction of vehicle speed control/adjustment/indication, etc., can solve the problems of large swing force, mechanical structure vibration of optical disc drive, increase of data reading time, etc., to reduce noise and data. Reading time, anti-vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

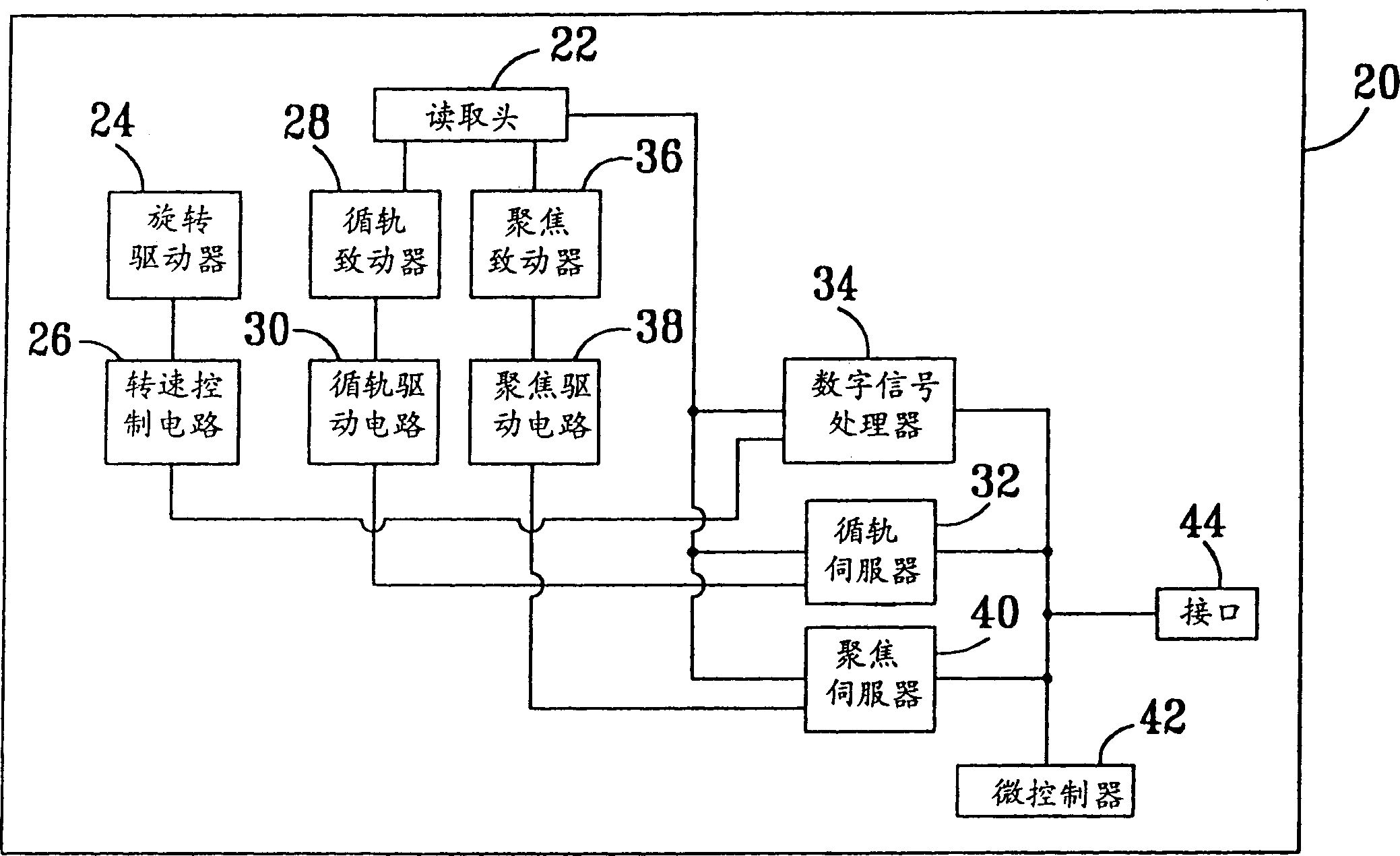

[0012] Please refer to figure 2 . figure 2 It is a functional block diagram of an optical disc drive 20 that can use the rotational speed adjustment method of the present invention. The optical disc drive 20 includes a pickup head 22 for reading data stored on a track of an optical disc and generating a data signal, a tracking servo signal and a focus servo signal. A rotary driver 24 is used to rotate the optical disk; a rotational speed control circuit 26 is used to control the rotational speed of the rotary driver 24; a track actuator 28 is used to move the pickup head 22 along the radial direction of the optical disk position; a tracking drive circuit 30, used to control the tracking actuator 28; a tracking servo 32, used to control the tracking according to the tracking servo signal generated by the read head 22 and a tracking loop gain The driving circuit 30 enables the tracking actuator 28 to radially move the pick-up head 22 to follow the track of the optical disc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com