Shield tunnel repairing reinforcing platform and reinforcing method

A technology for shield tunneling and reinforcement platforms, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems affecting the safety of subway tunnels, repair and reinforcement of subway tunnels that cannot be rounded, and wrong platforms, so as to save assembly and Debugging time, high-efficiency repair automation, and the effect of improving repair and reinforcement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

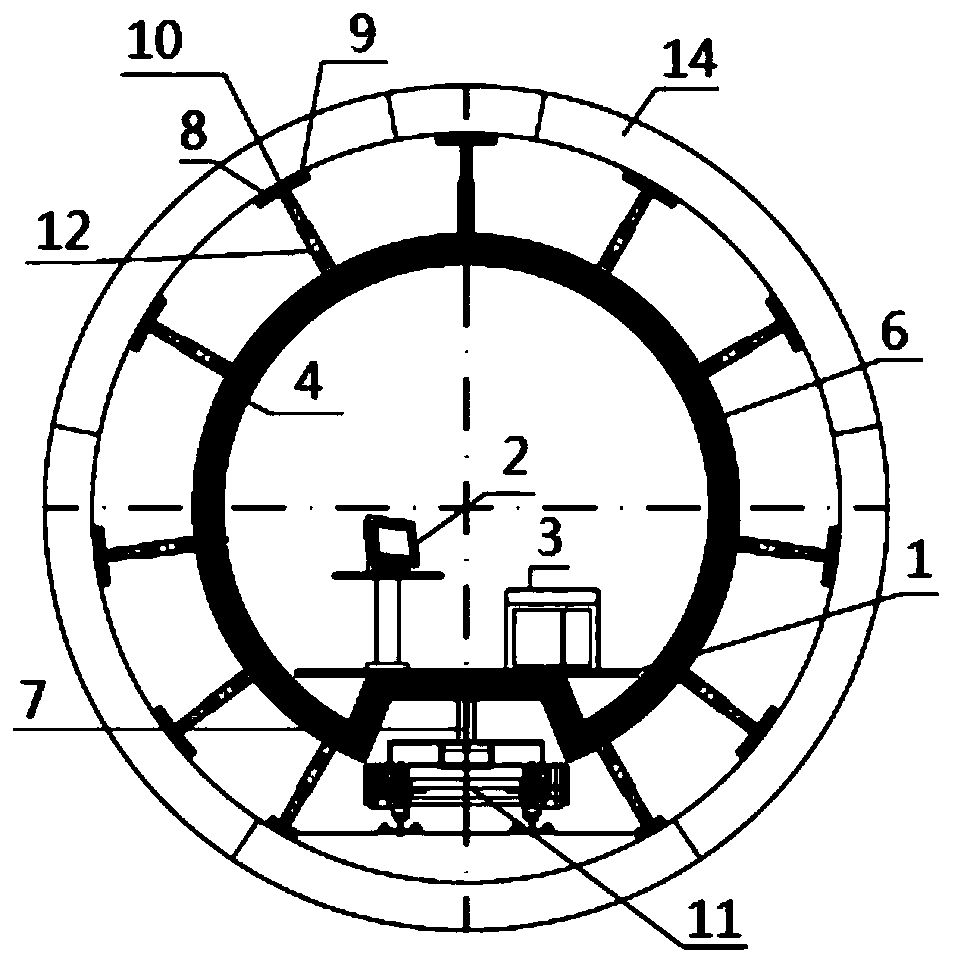

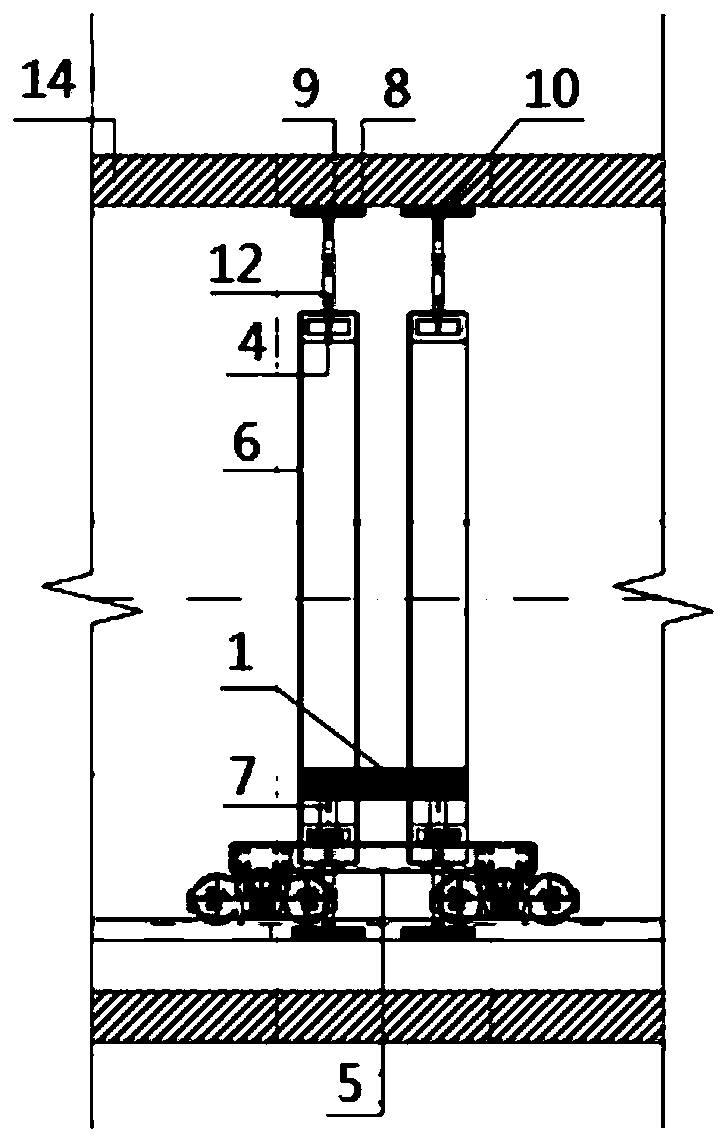

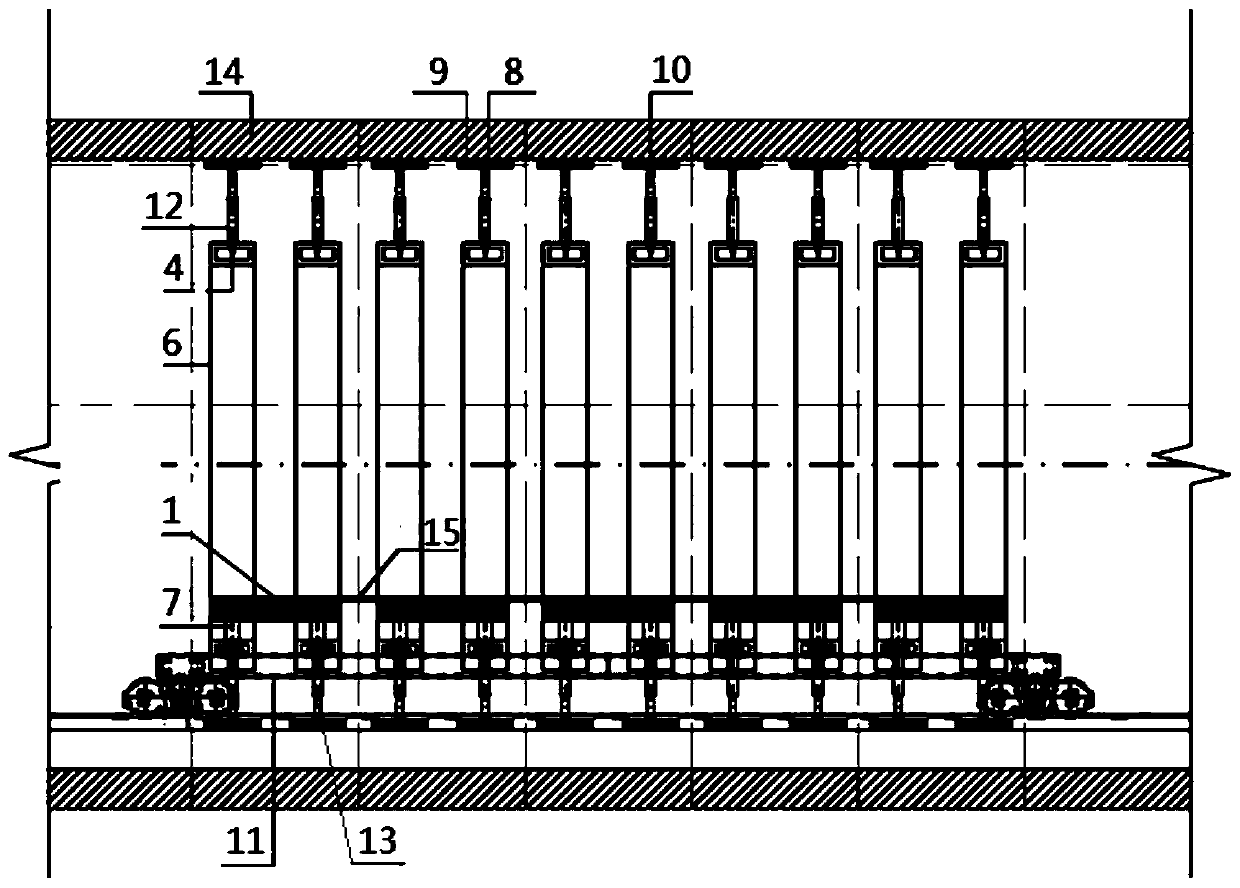

[0034] like figure 1 As shown, this embodiment provides a shield tunnel repair and reinforcement platform, which is used to solve the complexity and limitation of the repair and reinforcement operation of the rounder of the traditional shield machine, and realize the cracking, misalignment, and Rapid treatment of problems such as differential settlement and water leakage, and the method is simple, which can greatly reduce the impact on the operation of subway tunnels, including operating platform 1, control host 2, hydraulic switchboard 3, hydraulic oil pipeline 4, rod-shaped hydraulic jack 12, Frame main shaft 6, telescopic bracket 7, curved steel plate 8, rubber pad 9, universal ball 10 and platform base 11.

[0035] like figure 2 As shown, each sub-platform of the shield repair and reinforcement platform is composed of a platform base 11, a telescopic support 7 and a frame main shaft 6, and the two frame main shafts 6 are connected to form an operation platform 1 of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com