Jack for hydraulic bracket, modularized cylinder bottom of jack and cylinder bottom preparation technology

A preparation process and modular technology, which is applied to mine roof supports, pillars/supports, mining equipment, etc., can solve the problems of difficulty in ensuring processing accuracy, difficult to guarantee processing accuracy, affecting the performance of jacks, etc., to reduce processing costs and reduce processing. Difficulty, easy to fix the effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

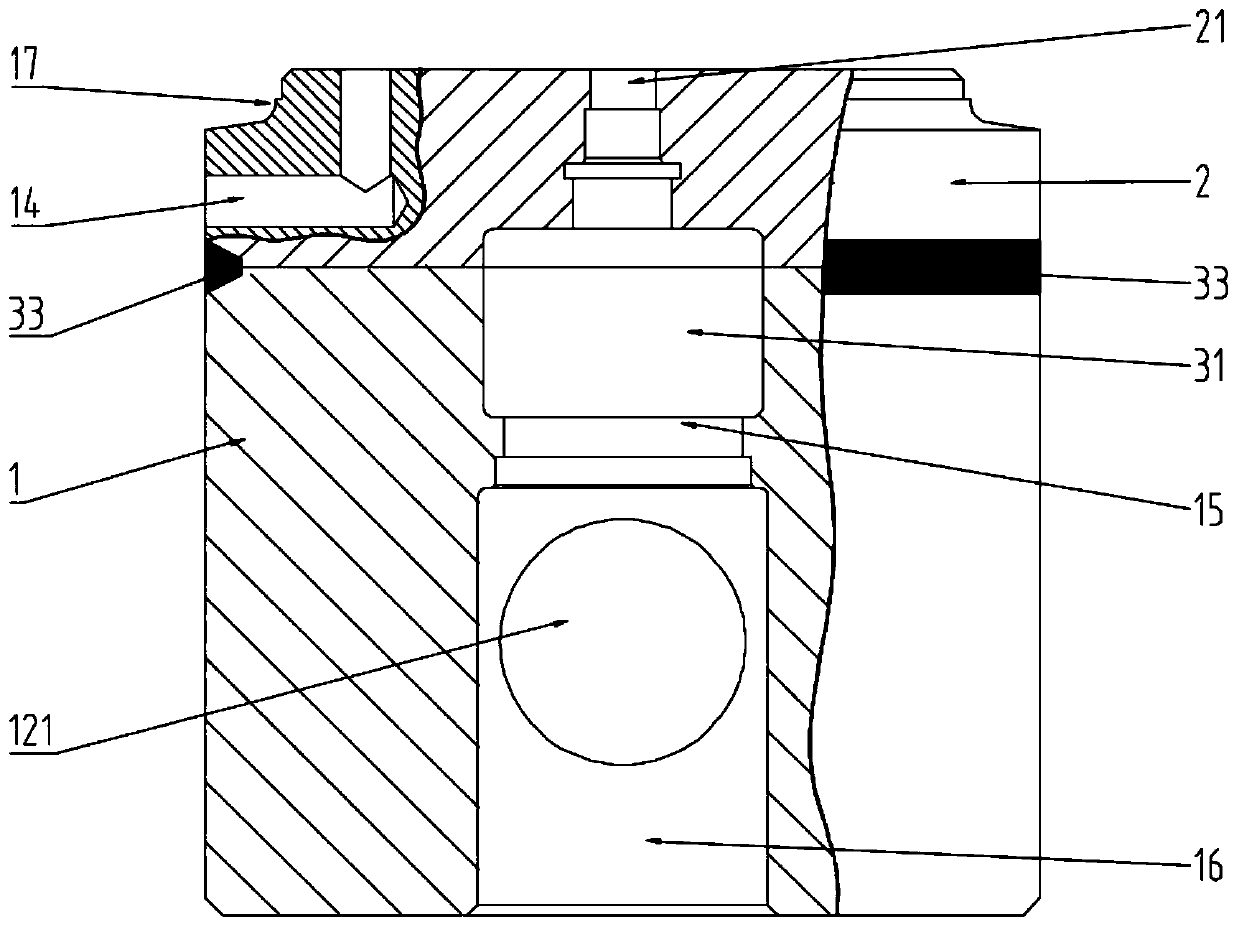

[0096] refer to Figure 1-Figure 3 , the present invention provides a modular cylinder bottom, comprising a main body module 1 and a sensor module 2 , the sensor module 2 is fixedly connected to the main body module 1 ; the sensor module 2 is provided with a sensor through hole 21 .

[0097] Using the above scheme, the sensor module 2 is used to install the stroke sensor 5, such as Figure 10 As shown, it can be replaced with different sensor modules 2 according to different stroke sensor 5 models; the main body module 1 and the sensor module 2 are assembled and fixed together to form the cylinder bottom 3 of the hydraulic support jack, which can be selected according to different support connection methods Different main modules 1; in actual production, the diversification of the overall specifications of the cylinder bottom 3 is reduced, and the optional combination of the main module 1 and the sensor module 2 can be installed into a variety of finished products to meet vari...

Embodiment 2

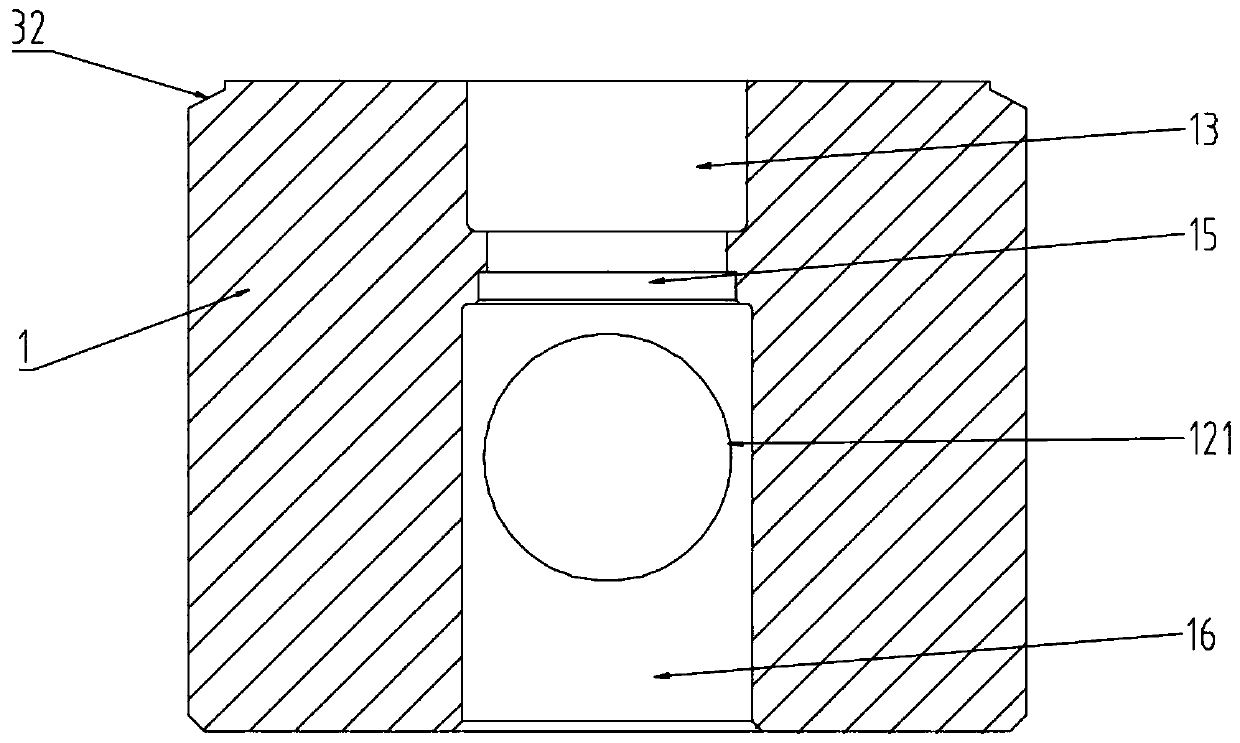

[0121] refer to Figure 4-Figure 6 , the present invention provides a modular cylinder bottom, comprising a main body module 1 and a sensor module 2 , the sensor module 2 is fixedly connected to the main body module 1 ; the sensor module 2 is provided with a sensor through hole 21 .

[0122] Using the above scheme, the sensor module 2 is used to install the stroke sensor 5, such as Figure 10 As shown, it can be replaced with different sensor modules 2 according to different stroke sensor 5 models; the main body module 1 and the sensor module 2 are assembled and fixed together to form the cylinder bottom 3 of the hydraulic support jack, which can be selected according to different support connection methods Different main modules 1; in actual production, the diversification of the overall specifications of the cylinder bottom 3 is reduced, and the optional combination of the main module 1 and the sensor module 2 can be installed into a variety of finished products to meet variou...

Embodiment 3

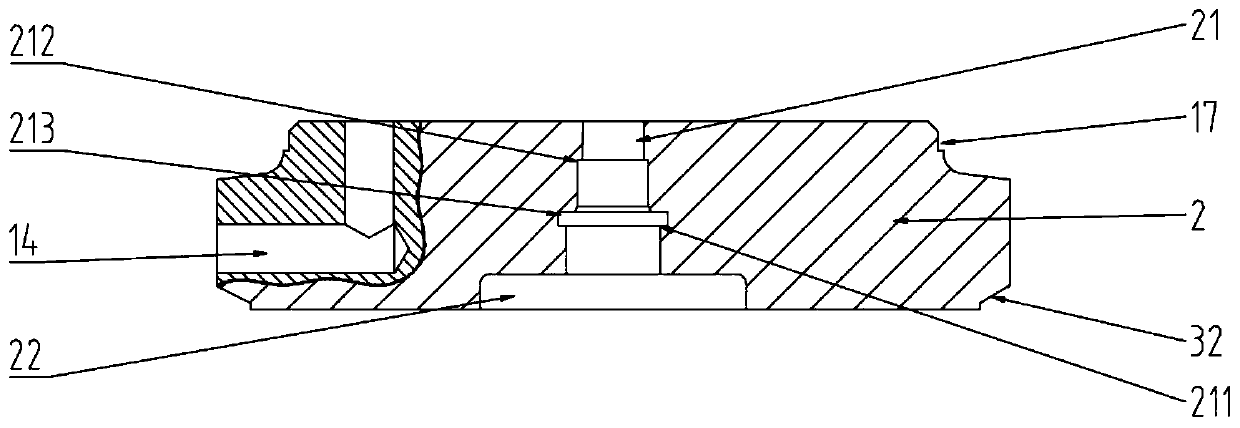

[0148] refer to Figure 7-Figure 9 , the present invention provides a modular cylinder bottom, comprising a main body module 1 and a sensor module 2 , the sensor module 2 is fixedly connected to the main body module 1 ; the sensor module 2 is provided with a sensor through hole 21 .

[0149] Using the above scheme, the sensor module 2 is used to install the stroke sensor 5, such as Figure 10 As shown, it can be replaced with different sensor modules 2 according to different stroke sensor 5 models; the main body module 1 and the sensor module 2 are assembled and fixed together to form the cylinder bottom 3 of the hydraulic support jack, which can be selected according to different support connection methods Different main modules 1; in actual production, the diversification of the overall specifications of the cylinder bottom 3 is reduced, and the optional combination of the main module 1 and the sensor module 2 can be installed into a variety of finished products to meet vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com